Description

3D printer Markforged X7 Field Edition

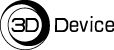

3D printer Markforged X7 Field Edition is a field version of the industrial printer X7. The device can be quickly assembled and launched in any conditions. Off-road delivery of the 3D printer will not affect its performance. The manufacturer Markforged has taken care of reliable protection of the device from vibrations, shocks, and impacts during transportation.

What distinguishes the Markforged X7 FE from conventional 3D printers?

Autonomous 3D printer with shock protection will withstand any tests. X7 Field Edition has a protective casing: Pelican AL3232 case with 1 lid. Individual foam modules and movable locking joints soften shocks during transportation and operation in extreme conditions. The X7 FE solution was included in MIL-STD-810 testing in support of the DoD Program of Record and showed excellent results. Field repairs with quick replacement of parts become a reality thanks to the industrial innovative 3D printer.

What areas is the field version of Markforged X7 FE suitable for?

The Markforged X7FE 3D printer will help to establish an uninterrupted supply of spare parts for the armed forces, for agricultural companies working in remote fields, for geological exploration expeditions, for factories and plants located far from industrial centers.

Increase the resilience of the supply chain in critical areas with the help of printing tools. Adapters and replacement parts for equipment are available as soon as they are needed.

The Markforged X7 FE will provide dimensional accuracy for the most critical tolerances with the help of a built-in laser micrometer and adaptive table leveling. 3D printing on site at gas production or sowing work will significantly increase the efficiency of work processes several times.

Print easily and quickly anywhere

A simple user interface for easy print setup, with built-in utilities for guided calibration and printer maintenance. The X7 FE mobile 3D printer can be fully configured and ready to print in minutes. It includes the materials, parts, and tooling you need to maintain production between restocking opportunities.

A lightweight, one-piece design, precision machined gantry, and laser calibration ensure consistent performance wherever you are.

Markforged X7FE Field Edition Features

- Pound for pound, watt for watt, Markforged printers are the most productive 3D printers on the planet.

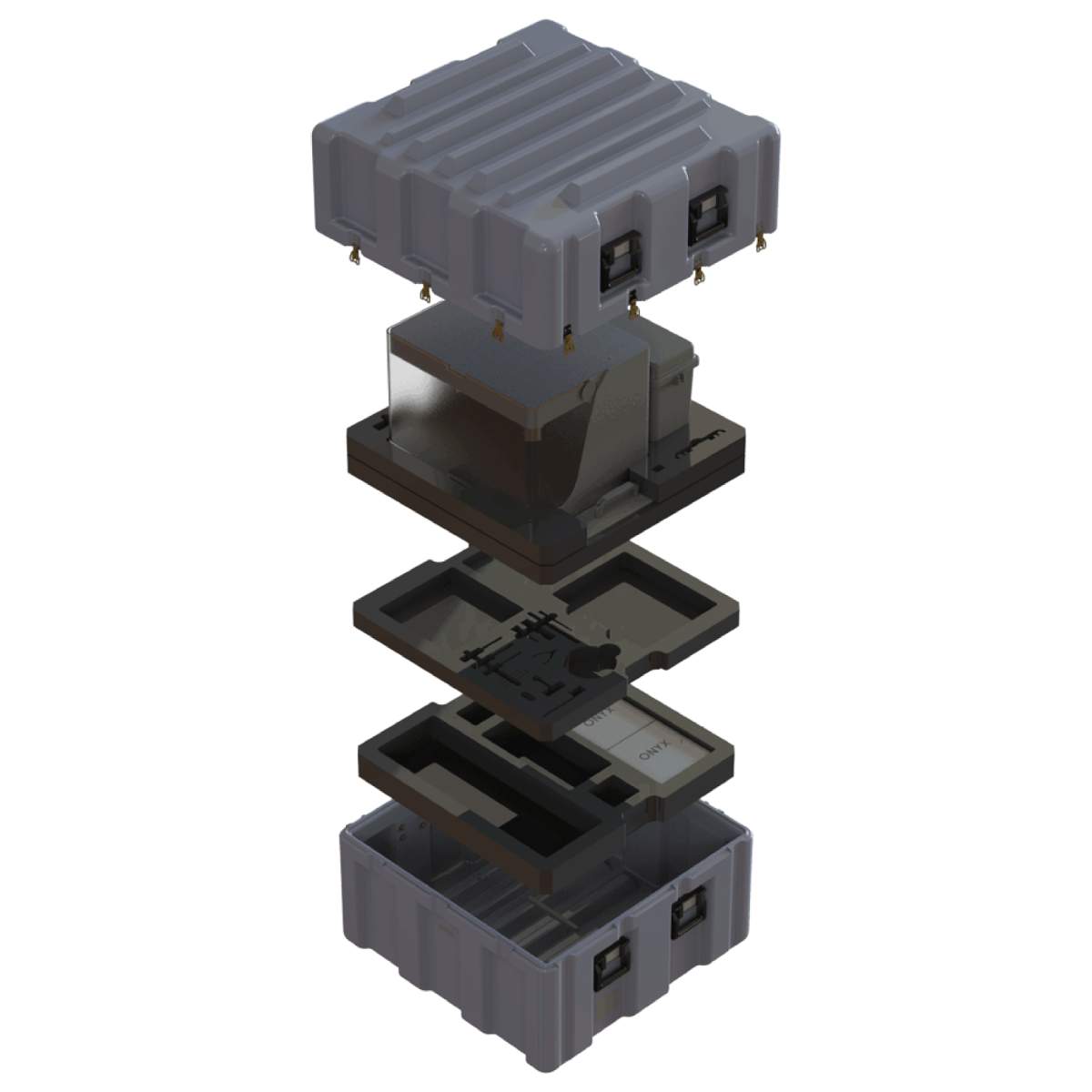

- Printed parts are stronger than aluminum with unique continuous carbon fiber reinforcement. No bulky heated chamber required, saving space, weight, and energy.

- Rugged and lightweight aluminum one-piece construction with precision machined gantry. Measures 584 x 483 x 914 mm (22.3 x 18.3 x 36.5 in) and weighs 48 kg (108 lbs).

- Uses less energy than a pair of incandescent bulbs. Uses standard AC power: 100-240 VAC, 150 watts (2 amp peak).

- Lightweight one-piece construction, precision machined gantry, and laser calibration ensure consistent performance wherever you are.

- Laser calibration helps operators maintain the machine in good working order under harsh conditions, transportation, and temperature fluctuations.

- The X7 FE extends the capabilities of Digital Forge, helping you produce parts with minimal effort at all times.

- The Markforged X7FE has an impressive build envelope of 330 mm x 270 mm x 200 mm. This allows you to print large components. Layer thicknesses range from 50 µm to 250 µm, ensuring parts are highly detailed and have a perfectly smooth surface.

- Carbon fiber-reinforced printed parts easily replace machined 6061 aluminum, reducing product weight and costs.

- Flame retardant and anti-static: special materials are suitable for creating safe parts for use in harsh environments.

- The ability to work with a variety of materials and complex geometries expands the range of applications.

- User-friendly Eiger software simplifies process management and integration into work systems.

Markforged X7FE Printing Technology

This industrial 3D printer uses the continuous fiber reinforcement (CFR) method. The technology combines basic composite materials with continuous fibers, which allows for the production of lightweight and durable products. This technology outperforms traditional manufacturing methods in terms of strength characteristics. By purchasing the printer together with a set of materials, you can start printing immediately after installation.

Working area and accuracy

Markforged X7FE has impressive dimensions of the working area – 330 mm x 270 mm x 200 mm. This allows you to print large components. Layer thicknesses range from 50 microns to 250 microns, providing products with high detail and a perfectly smooth surface.

Print Materials

Markforged X7FE supports the following materials:

- Onyx®: Nylon with micro carbon reinforcement for strong, heat-resistant parts.

- Onyx FR™: Flame-retardant version of Onyx with UL 94 V-0 rating.

- Onyx ESD™: Material for anti-static parts.

- Nylon: General-purpose plastic with good flexibility.

- Precise PLA: Easy-to-use prototyping material.

- Smooth TPU 95A: Flexible material for flexible parts.

- Carbon Fiber: Maximum strength and stiffness.

- Carbon Fiber FR: Flame-retardant version of carbon fiber.

- Glass Fiber: Increases stiffness and strength.

- Kevlar® (aramid fiber): High impact resistance.

- HSHT Glass Fiber: Withstands high temperatures.

Eiger Software

Eiger software helps you conveniently manage your prints directly from your web browser. The app automatically updates, allows you to organize the work of several devices in real time, and provides cloud access for collective work. This simplifies the printing process and increases productivity.

Laser scanning

The printer is equipped with a built-in laser micrometer that scans the platform with an accuracy of up to 1 μm. This ensures a perfectly flat first layer and high dimensional accuracy of finished products. Thanks to this level of accuracy, the printer is suitable for printing complex miniature objects.

Reliability and productivity

The printer is equipped with a robust frame and a precision removable table with a repeatability of 10 μm. This ensures consistent print quality and high reliability in production conditions.

Connections and protection

The printer is compact enough for industrial equipment and is conveniently placed in limited space. Connection is via USB, Wi-Fi or Ethernet, autonomous work is possible.

Markforged X7 FE is an advanced 3D printer with continuous fiber reinforcement. High accuracy, reliability, and a variety of supported materials make it ideal for creating durable and functional parts in industry and other fields.

Thanks to the unique solution for protection against vibrations and shocks, the 3D printer can be transported to any location. Printing in the field can be provided within minutes after the 3D printer is delivered.

Technical specifications Markforged X7 FE:

| Printing Technology | Continuous Fiber Reinforcement (CFR) |

| Build Field (mm) | 330*270*200 mm |

| Ø Of Plastic (mm) | 1,75 |

| Number Of Extruders | 2 |

| Chamber Type | Closed |

| Heating The Chamber | Yes |

| Autocalibration | Yes |

| Feeder Type | Direct |

| Layer Height (micron) | 50 – 250 |

| Extruder Construction Type | Second generation extruder, detection of plastic absence |

| Leveling System | Kinematic connection of the printing platform – flat with an accuracy of up to 80 µm Laser leveling of the platform, active calibration of the print |

| Maximum Chamber Temperature (°C) | 60 |

| Automatic Filament Switching | Yes |

| Platform Material | Precision ground print platform |

| Internal Part Geometry | Closed Cell or Solid Infill |

| Supported Materials | Plastic: Onyx, Onyx FR, Onyx ESD, Nylon White, P-PLA, S-TPU Available Fibers: Carbon Fiber, Carbon Fiber FR, Fiberglass, Aramid Fiber (Kevlar®), Fiberglass HSHT |

| Features | Precision design Continuous fiber reinforcement (CFR) Filling: solid or closed cells |

| Software | Eiger Cloud |

| Connectivity | Wi-Fi, Ethernet |

| Power Requirements | 100–240 VAC, 150 W (2 A peak) |

| Manufacturer Country | USA |

| Weight Netto (kg) | 86 |

| Dimensions Netto (mm) | 914 x 914 x 762 |

Reviews

There are no reviews yet.