Description

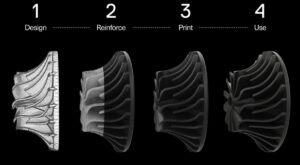

Markforged X7 – 3D printer with continuous fiber reinforcement

Markforged X7 – 3D printer with continuous fiber reinforcement, combines advanced printing technologies, high precision and reliability. The device is an ideal solution for the production of functional and durable parts in various industries. This is a 3D printer, the cost of which pays off very quickly. Depending on the features of use, the device begins to generate profit in 6-12 months.

Benefits of using Markforged X7

High strength of parts: products printed using carbon fiber can replace processed aluminum 6061, reducing costs and weight.

Fire resistance and antistatic: special materials allow you to create parts for use in conditions of increased safety requirements.

Production flexibility: support for various materials and the ability to print complex geometries expand the range of applications.

Integration with digital systems: Eiger software provides easy control of 3D printing and integration with existing workflows.

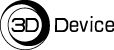

Markforged X7 Printing Technology

The Markforged X7 industrial 3D printer uses the continuous fiber reinforcement (CFR) process. By combining base filaments with continuous fibers, it is possible to obtain lightweight but durable products. This technology provides high product strength, superior to traditional manufacturing methods. You can buy a plastic 3D printer immediately with a set of necessary materials. This will allow you to start printing on the day of purchase.

Build area and accuracy of the X7 industrial 3D printer

The Markforged X7 printer has a working print area of 330 mm x 270 mm x 200 mm, which allows you to manufacture large components.

The layer thickness is adjustable from 50 μm to 250 μm. This ensures high detail and a smooth surface of the products.

Materials for printing a 3D printer with continuous fiber reinforcement. The surface quality of the finished product depends not only on the printer settings, but also on the quality of the 3D printing materials used in the process.

Markforged X7 is compatible with a wide range of materials:

- Onyx®: Nylon reinforced with micro carbon fibers for high stiffness and heat resistance.

- Onyx FR™: A flame-retardant version of Onyx with a UL 94 V-0 rating.

- Onyx ESD™: An anti-static material for electronic applications.

- Nylon: A versatile plastic with good strength and flexibility.

- Precise PLA: An easy-to-use material for prototyping.

- Smooth TPU 95A: A flexible material for flexible parts.

- Carbon Fiber: Provides maximum strength and stiffness.

- Carbon Fiber FR: A flame-retardant version of carbon fiber.

- Fiberglass: Increases strength and stiffness.

- Aramid Fiber (Kevlar®): Provides high impact resistance.

- HSHT Glass Fiber: Withstands high temperatures and mechanical stress.

Eiger Software

The intuitive Eiger software allows you to manage the printing process via a web browser. It supports automatic version updates, real-time fleet management, and cloud collaboration, simplifying production and increasing efficiency.

Laser scanning for precision

The built-in laser micrometer scans the print bed with an accuracy of 1 µm, creating a contour map of the surface. This ensures perfect alignment of the first layer and high dimensional accuracy of the finished parts. Thanks to the high resolution and precision, you can use the 3D printer to print miniatures.

Reliability and productivity

The printer is equipped with a reinforced, precisely machined frame and a precision print table that can be removed and installed with a repeatability of 10 µm. This ensures consistent print quality and high productivity in industrial conditions.

Dimensions and weight of Markforged X7

The printer’s dimensions are 584 mm x 483 mm x 914 mm, and its weight is 48 kg, which makes it compact and convenient for placement in production facilities.

Connection interfaces

The Markforged X7 supports USB, Wi-Fi and Ethernet connections, providing flexibility in integrating with various systems and ease of use. If you are looking for a 3D printer for home use, it is better to buy a simpler model, such as the Markforged Mark Two. Although, with space and proper connection, the device can be placed in an apartment.

The Markforged X7 3D printer combines advanced printing technologies with continuous reinforcement, high accuracy and reliability, making it an ideal solution for the production of functional and durable parts in various industries.

Technical specifications Markforged X7:

| Printing Technology | Continuous Fiber Reinforcement (CFR) |

| Build Field (mm) | 330*270*200 mm |

| Ø Of Plastic (mm) | 1,75 |

| Number Of Extruders | 2 |

| Chamber Type | Closed |

| Heating The Chamber | Yes |

| Autocalibration | Yes |

| Feeder Type | Direct |

| Layer Height (micron) | 50 – 250 |

| Extruder Construction Type | Second generation extruder, detection of plastic absence |

| Leveling System | Kinematic connection of the printing platform – flat with an accuracy of up to 80 µm Laser leveling of the platform, active calibration of the print |

| Maximum Chamber Temperature (°C) | 60 |

| Automatic Filament Switching | Yes |

| Platform Material | Precision ground print platform |

| Internal Part Geometry | Closed Cell or Solid Infill |

| Supported Materials | Plastic: Onyx, Onyx FR, Onyx ESD, Nylon White, P-PLA, S-TPU Available Fibers: Carbon Fiber, Carbon Fiber FR, Fiberglass, Aramid Fiber (Kevlar®), Fiberglass HSHT |

| Features | Precision design Continuous fiber reinforcement (CFR) Filling: solid or closed cells |

| Software | Eiger Cloud |

| Connectivity | Wi-Fi, Ethernet |

| Power Requirements | 100–240 VAC, 150 W (2 A peak) |

| Manufacturer Country | USA |

| Weight Netto (kg) | 48 |

| Dimensions Netto (mm) | 584 x 483 x 914 |

Reviews

There are no reviews yet.