Description

Industrial 3D printer Markforged X3 – fast printing with high accuracy

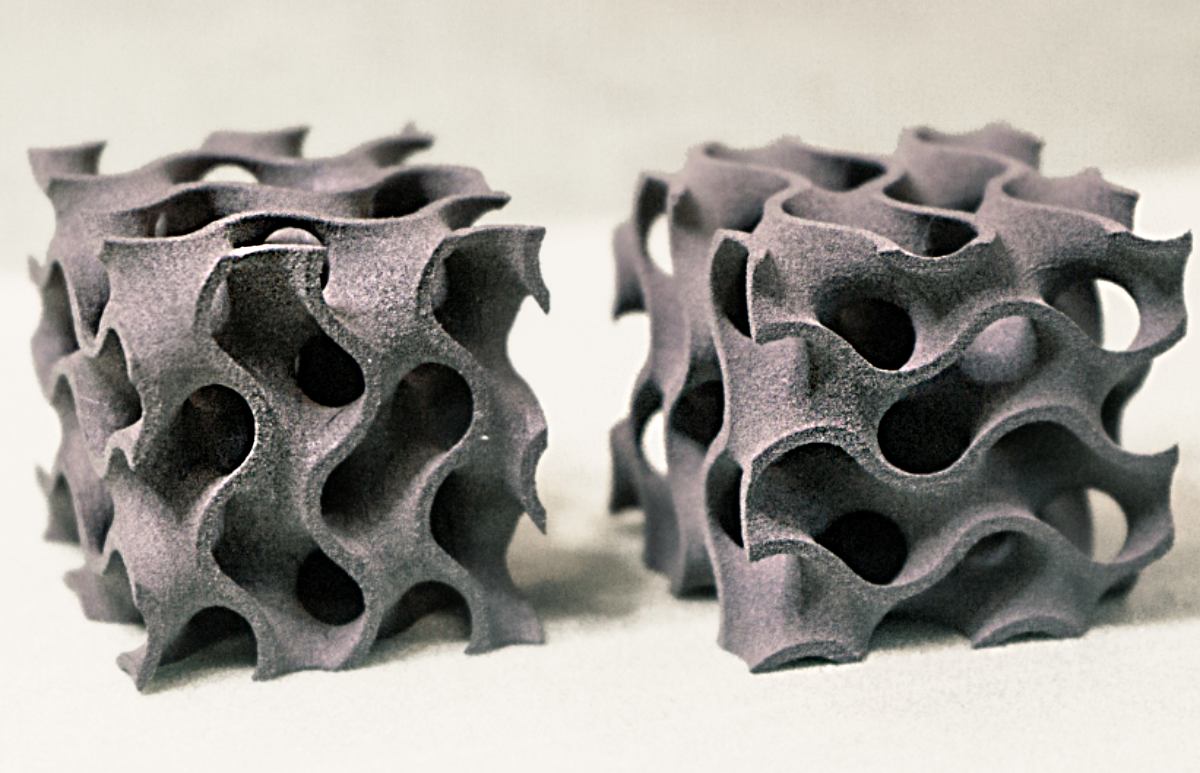

Industrial 3D printer Markforged X3 is an advanced productive and reliable printer, designed for intensive use. Thanks to precise mechanical processing, modern sensors and unique software, this printer provides exceptional reliability and the highest accuracy.

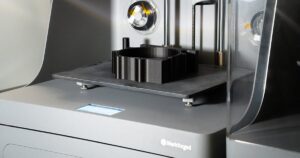

High detail and smooth surface – the result of the 3D printer Markforged X3

Innovative printing and control technologies allow you to create products with an almost perfectly smooth surface. The device supports several printing modes, which makes it universal for performing tasks of varying complexity. High resolution (from 50 microns) ensures the creation of parts with unrivaled accuracy and minimally noticeable layers.

The fusion printing process guarantees a uniform structure, high strength and an aesthetic appearance. Industrial 3D printer Markforged X3 supports the function of printing with filling of closed cells, which by default have a triangular shape, but other geometry options are also available.

A wide range of high-quality materials for different types of products

Markforged X3 works with three types of nylon materials reinforced with micro-carbon fibers, using Fused Filament Fabrication (FFF) technology. The printer is capable of working without interruptions, which allows you to produce any volume of products without limiting production capabilities.

The second-generation extruder is equipped with plastic feed sensors and a laser for scanning. This system dynamically adjusts the parameters of the first layers, providing excellent adhesion to the platform. Markforged X3 creates durable and lightweight parts from modern materials that are suitable for a wide range of applications: from prototyping to finished products.

Powerful, reliable and productive 3D printer Markforged X3 is always ready to print

This 3D printer is not just a device, but a powerful tool for the implementation of your wildest ideas. With its help, you can quickly and economically produce prototypes, equipment, tools and finished products of any complexity. The large 330 x 270 x 200 mm build plate provides ample space for printing large parts. All major components, including the extruder, guides and table, are easily replaceable, but thanks to the high resource of the equipment, you will have many hours of flawless operation before they need to be replaced.

Markforged X3 is your reliable assistant for creating high-precision and durable products, saving time and resources.

Technical specifications:

| Printing Technology | FFF filament fusion method |

| Build Field (mm) | 330*270*200 mm |

| Ø Of Plastic (mm) | 1,75 |

| Number Of Extruders | 2 |

| Chamber Type | Closed |

| Heating The Chamber | Yes |

| Autocalibration | Yes |

| Feeder Type | Direct |

| Layer Height (micron) | 50 – 200 |

| Extruder Construction Type | Second generation extruder, detection of plastic absence |

| Leveling System | Kinematic connection of the printing platform – flat with an accuracy of up to 80 µm Laser leveling of the platform, active calibration of the print |

| Maximum Chamber Temperature (°C) | 60 |

| Automatic Filament Switching | Yes |

| Platform Material | Precision ground print platform |

| Internal Part Geometry | Closed Cell or Solid Infill |

| Supported Materials | Onyx, Onyx FR, Onyx ESD, Nylon White, P-PLA, S-TPU |

| Features | Precision design FFF filament fusion printing Filling: solid or closed cells |

| Software | Eiger Cloud |

| Connectivity | Wi-Fi, Ethernet |

| Power Requirements | 100–240 VAC, 150 W (2 A peak) |

| Manufacturer Country | USA |

| Weight Netto (kg) | 46 |

| Dimensions Netto (mm) | 584 x 483 x 914 |

Reviews

There are no reviews yet.