Three-Dimensional Bioprinting of Tubular Structures

The creation of blood vessels and arteries from real living tissue using a 3D bioprinter is gradually gaining momentum and transforming into a separate branch of 3D biotechnology. Three-dimensional bioprinting is rapidly developing, and its application in creating various tubular structures is becoming an increasingly popular practice. However, its widespread adoption is hindered by numerous limitations imposed by the very principles of 3D printing.

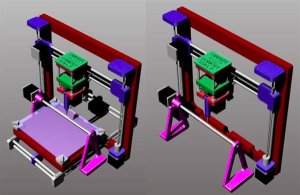

Naturally, researchers are looking for ways to overcome existing challenges and sometimes find very original solutions to the problems at hand. For example, a team of Argentine scientists decided to optimize a standard 3D bioprinter by adding a fourth axis. According to the developers, three-dimensional bioprinting on such a device will remove many limitations when reproducing hollow, tubular structures of various configurations.

Optimized 3D Printer

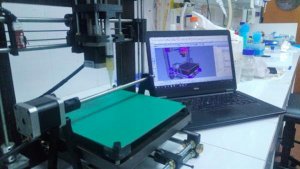

This unique development belongs to a team of researchers from CONICET and the National University of La Plata, led by Dr. Guillermo R. Castro. Their initial goal was the creation of hollow tubular structures. Facing difficulties and limitations when working with standard bioprinting, the scientists decided to develop their own method for reproducing volumetric structures. This required optimizing existing equipment. So, what is the essence of this original improvement?

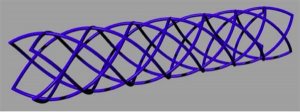

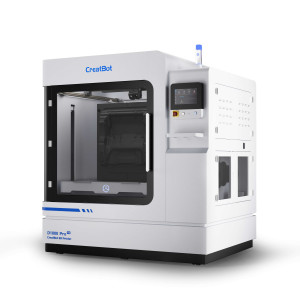

Traditional three-dimensional bioprinting is performed using standard devices with three XYZ axes. The researchers’ idea was to equip a standard 3D printer with a rotating fourth axis. Essentially, this is not even a true axis, but rather a cylindrical, rotating build surface. The printing material is applied directly to its surface. The axis rotates both clockwise and counterclockwise, allowing for the reproduction of various structural combinations.

Three-Dimensional Bioprinting Using the New Method

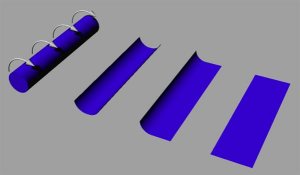

As the developers explain, standard FDM 3D printing requires each new layer of material to be applied on top of the previous one, which inevitably creates difficulties in producing complex elements. The researchers focus particularly on cylindrical, tubular, and spiral structures. The three-dimensional bioprinting method they developed allows for the reproduction of all necessary elements on a 3D printer equipped with an injector with interchangeable nozzles.

Regarding materials, the team is considering the use of various biopolymer blends containing alginate, pectin, chitosan, and hydrogel. Depending on specific goals, these compositions are adjusted and modified. Ultimately, the developers aim to find the optimal mixture for the growth of living cells within 3D-printed scaffolds. In the future, this method could be successfully used to fabricate replicas of blood vessels and other tubular structures of the human body.

Leave a Comment