3D Printing and Post-Processing

Any owner of a 3D printer will sooner or later think about improving the appearance of printed products. Sometimes it is needed for decorative purposes, sometimes enthusiasts just want to experiment. In any case, such experience is an integral part of mastering 3D technologies. Unfortunately, FDM 3D printing does not allow achieving a completely smooth surface of the created objects. Regardless of the accuracy of reproduction, the layering will still be visible. But what to do if a glossy surface is still needed? The conclusion is one: post-processing. There are several proven methods used to improve the appearance of products, and today we will talk about them.

Post-Processing Options

Household 3D printing is already advanced enough for 3D technology enthusiasts to master the methods of post-processing printed products. There are several common processing methods, and we will list them below.

- Manual sanding. A rather painstaking method that requires effort and time;

- Brush treatment with solvents (acetone, dichloroethane);

- Vapor treatment with acetone and dichloroethane;

- Manual polishing with solvents.

Now that we know the main methods of post-processing, let's talk about each of them in more detail. We want to immediately draw your attention to the fact that when working with solvents, safety measures must be observed. These are toxic substances, and during their use, it is advisable to use protective equipment (goggles, respirators). The room where the work is carried out should be well ventilated. It is definitely worth wearing nitrile or neoprene gloves on your hands.

3D Printing and Manual Processing

The simplest and safest post-processing method is manual sanding. For this, you should take sandpaper or a fine-grained sanding sponge. This method does not allow achieving a glossy surface but will help remove layering and make the surface smoother. In combination with priming and subsequent painting, this method allows achieving excellent results. The only drawbacks are the duration and complexity of this method. The 3D printed products in the photo below were finished using this method. After sanding, the objects were primed, painted, and varnished.

Solvent Processing

Working with solvents includes several options. This includes brush treatment, manual processing, and vapor treatment with solvents. Let us clarify immediately: acetone is used for post-processing products made of ABS plastic, and dichloroethane for objects made of PLA plastic. Dichloroethane is also used for gluing parts.

When brush processing, you should choose a brush with natural bristles. Do not take too much or too little solvent to avoid possible drips and streaks. Overall, this is a very good processing method, which, however, requires great accuracy and concentration.

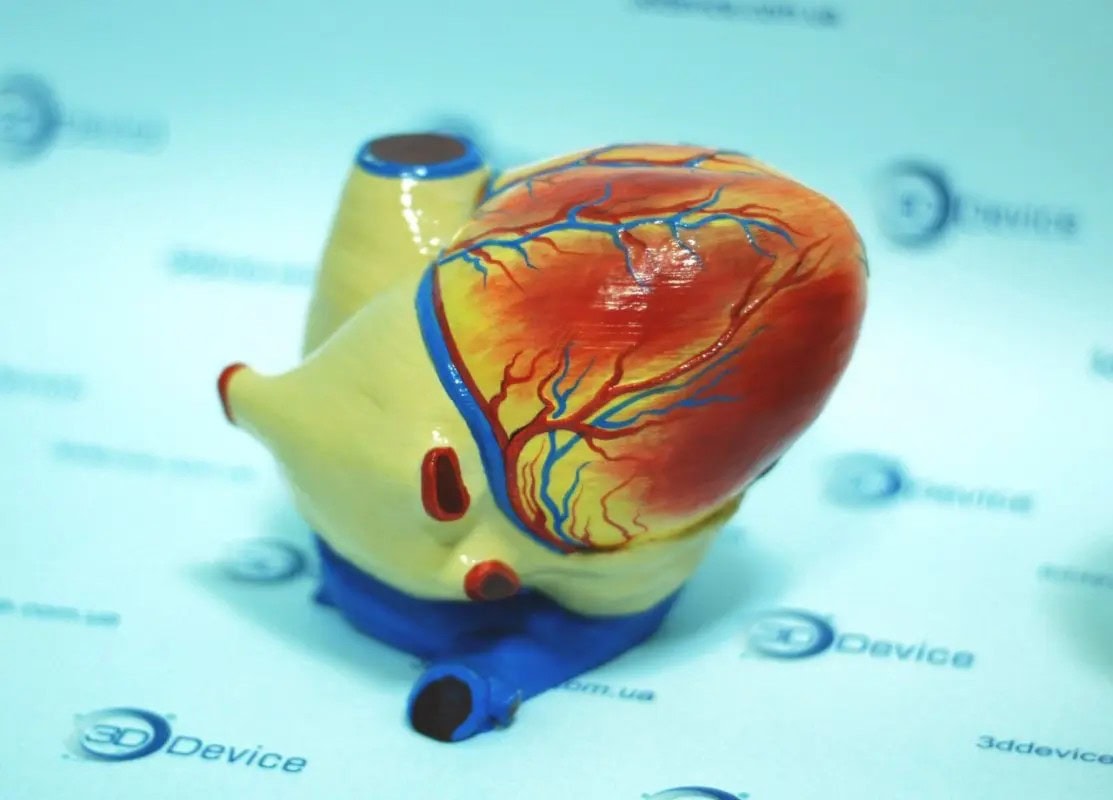

For manual polishing, a small amount of solvent and a piece of natural fabric are used. The solvent is applied to the fabric, after which the product is polished manually to smoothness. The product in the photo below was processed using this technology.

Vapor treatment with solvents should be carried out in a well-ventilated room, as their vapors are toxic. However, this method shows the best results in terms of the quality of processed products offered by FDM 3D printing. The object is placed on a non-soluble platform (metal is best) in a sealed container. Solvent is poured at the bottom of the container so that it does not touch the object. Then this container is heated, resulting in the evaporation of the solvent. Important: never put it on a strong fire, a small temperature is enough. The bust shown in the photo below was printed from ABS plastic and processed with acetone vapors.

3D Printing and Product Painting

Now let's talk about the decorative component. By itself, FDM 3D printing, especially on simple devices, is not capable of producing quality colored products. Therefore, sometimes there is a need to resort to manual painting. Acrylic paints, primers, and varnishes are perfect for this. If the product needs to be monochrome, it is better to use spray paints. It is always more convenient to take primer and varnish in spray form.

First, the model should be prepared: if necessary, sanded, cleaned of dust, and degreased. Now the primer is applied in several layers. It is very important to let it dry, as the quality of the painting depends on it. Now acrylic paint is applied, also in several layers. Let the paint dry completely, then fix the result with varnish. Post-processing is complete. Below are photos of painted products.

Order 3D Printing and Post-Processing

We want to remind you that our company offers to order 3D printing with subsequent post-processing at an affordable price. We perform all types of mechanical processing, as well as painting of any complexity. For any questions, please contact us in any way convenient for you, specified in the "Contacts" section. We look forward to cooperating with you!

Leave a Comment