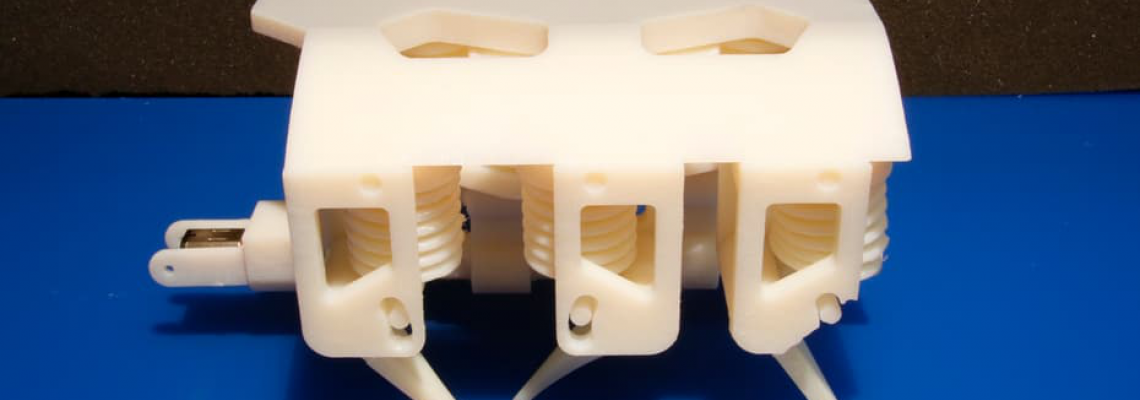

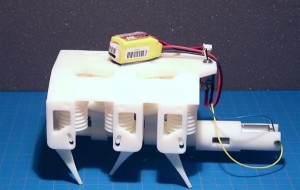

3D printing of robots — the first robot in the world has been created!

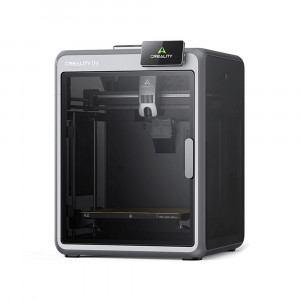

Scientists from the Computer Science and Artificial Intelligence Laboratory (CSAIL) at the Massachusetts Institute of Technology have developed a one-of-a-kind fully functional mechanism powered by hydraulics. Most interestingly, such robots can be manufactured on ordinary, commercially available 3D printers and do not require final assembly. The method, called “printable hydraulics,” solves two major challenges in additive manufacturing and advanced robotics technologies. First, until now, the inclusion of individual hydraulic components in a finished mechanism has been an extremely complex and lengthy process. Second, although many modern 3D printers are equipped with multiple extruders for use in 3D printing materials of different densities, the simultaneous use of solid and liquid substances has been very difficult.

3D printing of robots — the first robot in the world has been created!

The CSAIL project, partially funded by the National Science Foundation, eliminates these limitations and proves that 3D printing with both solid and liquid materials in a single object is not only real but also relatively simple. This printing technology was first introduced in December 2015. Its principle lies in the use of an inkjet 3D printer to deposit layer by layer individual droplets of material, 20–30 microns in diameter, which subsequently form the three-dimensional object. Each layer consists of a photopolymer, which hardens under UV light, and a liquid substance that does not solidify. In addition, the solid material can be either rigid or flexible, depending on the intended purpose.

Leave a Comment