- Stock: In Stock

- Product code: 00-00000134

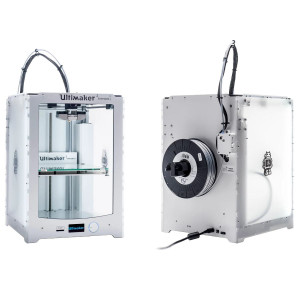

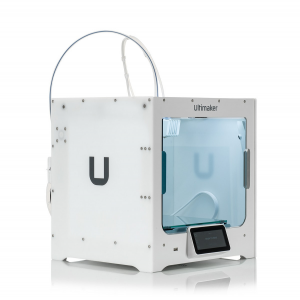

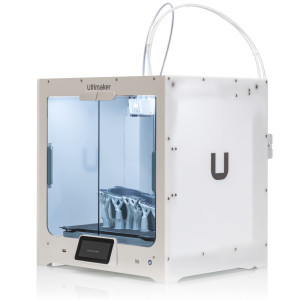

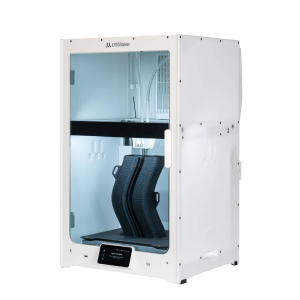

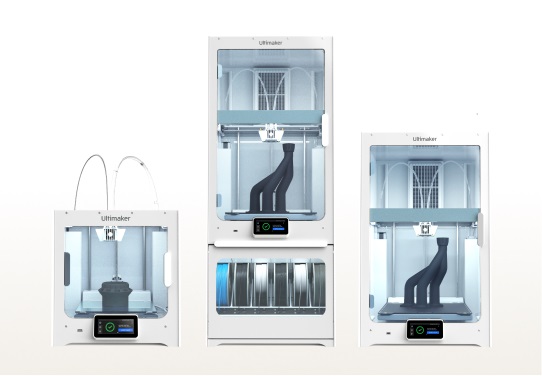

Professional UltiMaker S7 Pro Bundle 3D printer

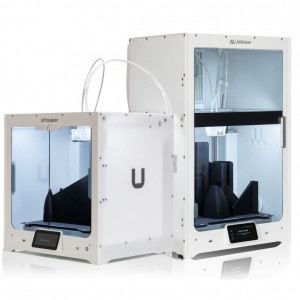

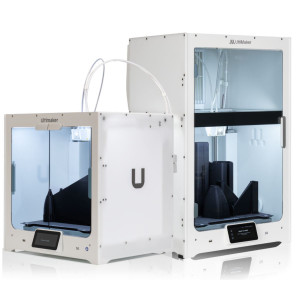

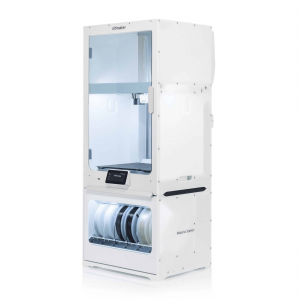

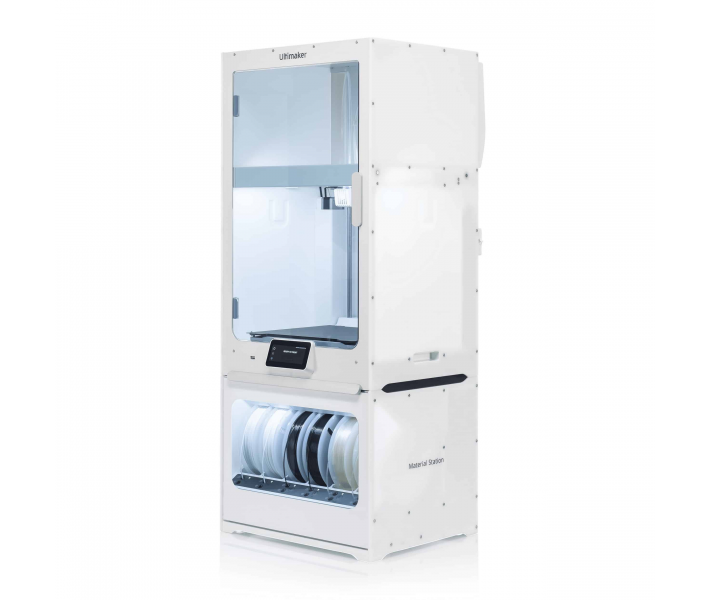

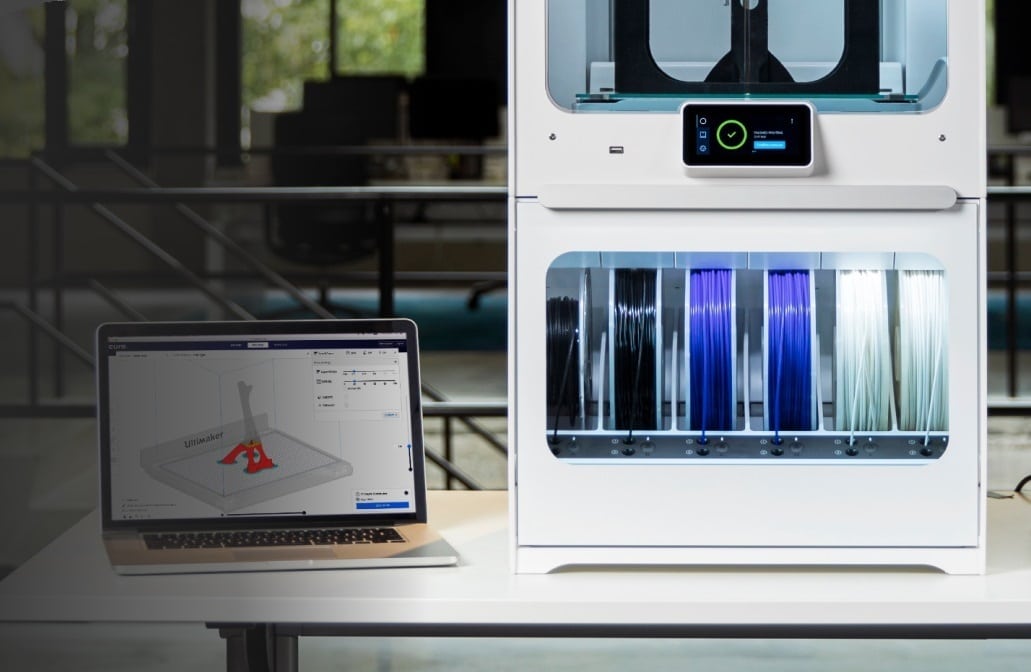

Introducing the UltiMaker S7 Pro Bundle 3D printer. A professional kit for long-term FDM printing consists of UltiMaker S7 Pro 3D Printer and the UltiMaker S7 Material Station. The Material Station turns your S7 into a powerful production hub and triples the material capacity. Automated filament processing. Humidity-controlled storage.

Printing equipment 24/7

No longer need to to constantly monitor the parameters and progress of printing, replacing materials manually, and the problem of proper humidity of raw materials, which greatly affects the printing result.

The UltiMaker S7 Pro Bundle automates these functions with the built-in Air Manager air control unit and a closed compartment for storing and automatically changing up to 6 filament spools – the Material Station.

The Material Station enables long and continuous FDM 3D printing without manual intervention: this one-of-a-kind upgrade further simplifies the 3D printing process by automatically switching up to 6 filament spools. It also controls the humidity inside the filament compartment and ensures that the material is delivered in perfect condition for high-quality 3D prints.

The printer’s huge build capacity and humidity-controlled material handling system increases print success rates, print quality, and uptime. This unlocks reliable production 24 hours a day, 7 days a week – while minimizing human error, print time, and operator time.

Main features

- Large working volume of 330*240*300 mm.

- Automatic material replacement during printing.

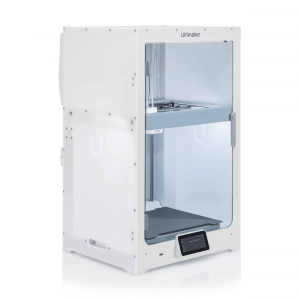

Material Station for storing and automatically replacing 6 spools at once – designed to be unattended and print 24/7. To load material into the Material Station, simply open the door and drop the spool into the compartment. During printing, any spool that is not in use can be turned off.

- Store materials in a controlled environment of up to 40% relative humidity.

Each spool is stored at 40% relative humidity, making it easy to implement more 3D printing applications with almost any combination of polymers and abrasive composites. Each of the Material Station bays has NFC readers and enhanced pre-feed devices for integration with UltiMaker Cura and Digital Factory.

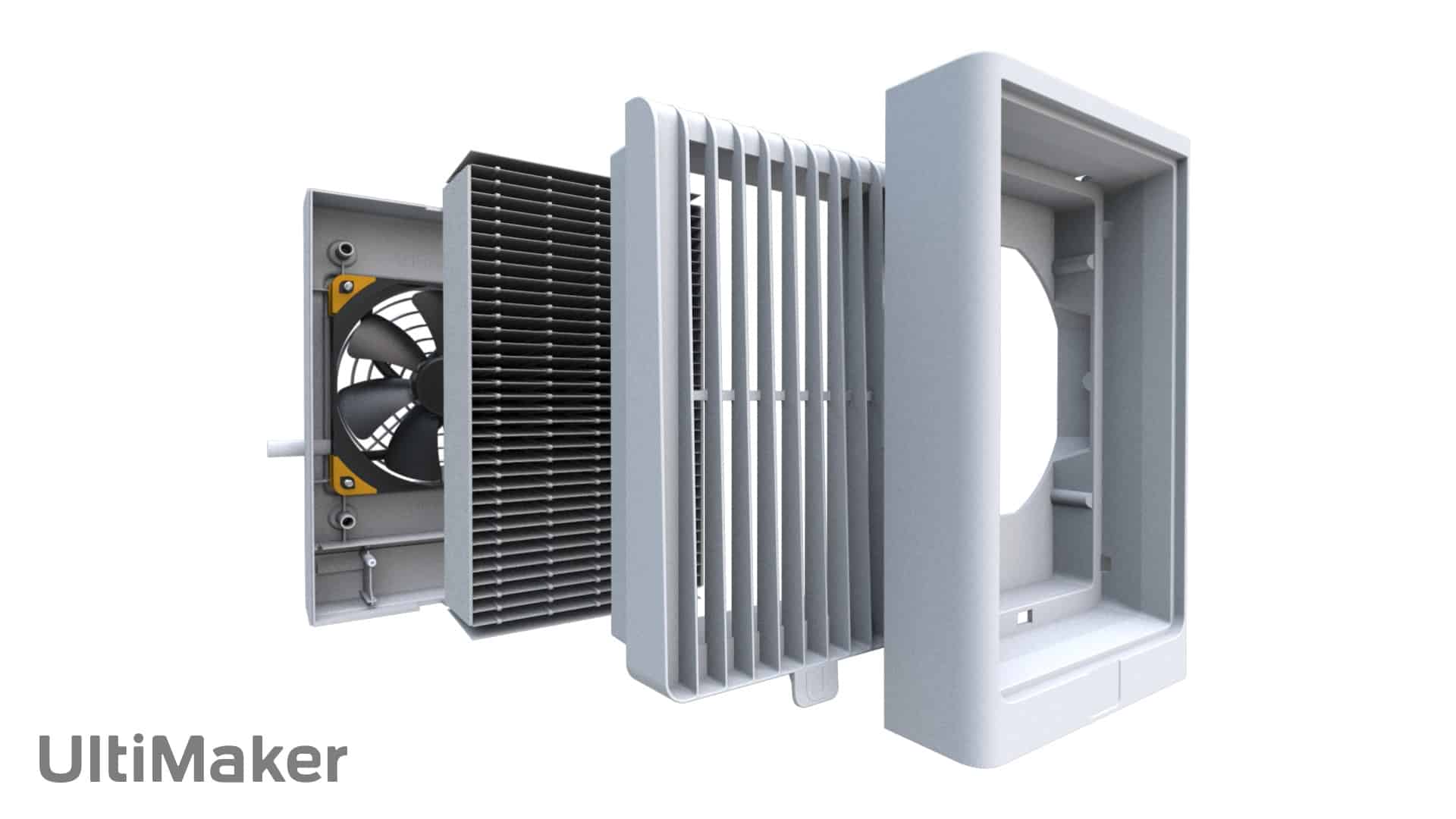

- Air Manager – built-in air control manager.

Independent testing has shown that up to 95% of the particles generated during the printing process are removed and released into the air. Cleaner indoor air and better print results in a closed print chamber.

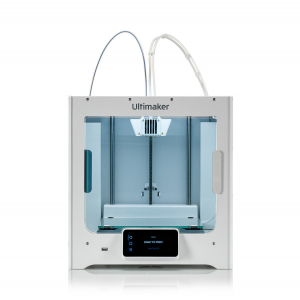

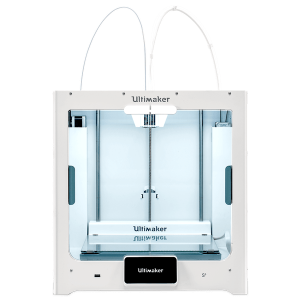

UltiMaker S7 Pro Bundle 3D Printer

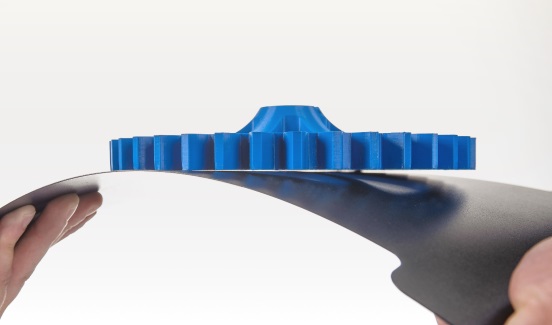

- Flexible PEI-coated print plate.

The unique PEI coating allows for quick and easy removal of the print without the use of adhesives. Then securely fasten it in place for a significant increase in productivity.

- More accurate inductive sensing.

The inductive sensor senses the build plate with less electrical noise and greater accuracy. Now you can really start printing and go – confident in a perfect first layer.

- Easily print from over 180+ materials at the touch of a button.

- Cura integration.

Get access to UltiMaker Cura features that speed up your workflow and improve print success, such as intent profiles, easy remote printing, and more.

- Backward file compatibility.

If you have an UltiMaker S5, your entire digital library of S5 print files will work seamlessly on the S7 – no re-cutting required.

- Nozzle blockage sensor.

The redesigned print head detects potential nozzle blockages earlier. It also contains stronger magnets to ensure that the print core door stays closed.

Professional 3D printing with the S7 Pro Bundle

The UltiMaker S7 Pro Bundle optimizes the storage and replacement of 3D printing materials, eliminating the need for manual labor. It has a closed, humidity-controlled chamber that keeps filaments in perfect printable condition. And during 3D printing, it reliably detects when one filament spool is running low and automatically switches to another. This helps to avoid human error and achieve better print quality even at night when you are not around.

Material Station integrates with UltiMaker S7, Cura and Digital Factory. With six front-loading NFC material bins and a simple, maintenance-free design, it’s never been easier to load, insert, and print with virtually any combination of polymers and abrasive composites to unlock more 3D printing applications.

Specifications

| Printing technology | FDM |

| Minimum layer height (micron) | 20 |

| Construction field (mm) | 330*240*300 |

| Plastic diameter (mm) | 2.85 |

| Maximum nozzle temperature (°C) | 280 |

| Number of extruders | 2 |

| Printing camera type | Closed |

| Camera heating | Passive |

| Plastic drying | Yes |

| Auto calibration | Yes |

| Feeding mechanism type | Bowden |

| Layer height (micron) | Nozzle 0.25 mm: 150 – 60 / Nozzle 0.4 mm: 200 – 20 / Nozzle 0.6 mm: 300 – 20 / Nozzle 0.8 mm: 600 – 20 |

| Nozzle diameter (mm) | 0.25 / 0.4 / 0.6 / 0.8 |

| Nozzle heating time (min) | 2 |

| Positioning accuracy (μm) | XY: 6.9; Z: 2.5 |

| Maximum platform temperature (°C) | 140 |

| Platform heating time (min) | Up to 5 (from 20 to 60 °C) |

| Platform material | Flexible steel plate with PEI coating |

| Supported materials | PLA, Tough PLA, Nylon, ABS, CPE, CPE+, PC, TPU95A, PP, PVA, Breakaway, more than 180 materials available |

| Material recognition | Automatic – NFC scanner |

| Operating noise, dB | >51 |

| Air filter | Replaceable HEPA filter |

| Management | 4.7″ color touch screen |

| Availability of a video camera | Yes |

| Features |

|

| Supported file types | STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG, G, GCODE, GCODE.gz, UFP |

| Software | UltiMaker Cura, UltiMaker Digital Factory, UltiMaker Essentials. Integration of plugins: SolidWorks, Siemens NX, Autodesk Inventor |

| Connection | Wi-Fi (2.4 and 5 GHz), Ethernet, USB |

| Input power | 100-240 V AC, 50-60 Hz |

| Output power | 500 W |

| System requirements | Mac OS, Windows, Linux |

| Certificates | CE, FCC, VPAT, RoHS, REACH, CB, BIS, KC, PSE, RCM, SRRC, MIC, NCC, safe professional use without supervision. ISO/IEC 27001 certificate. |

| Net weight (kg) | 29.1 |

| Assembled dimensions (mm) | 495×585×800 |

| Working environment temperature Range (°C) | 15 – 32 |

| Humidity range of the operating environment (%) | Up to 70 |

| Storage temperature (°C) | 0 – 32 |