- Stock: In Stock

- Product code: 00-08800248

UltiMaker PVA water-soluble filament for 3D Printing

UltiMaker PVA filament for 3D printing support structures when creating complex geometries with popular UltiMaker materials.

UltiMaker PVA is polyvinyl alcohol, which is an ideal support material for multi-extrusion 3D printing with water-soluble support structures that can be easily removed by simply soaking the model in water for a few hours. It allows you to create complex geometries with printed elements on water-soluble supports that leave a smooth surface after removal. Using support material in printing allows for unlimited creativity during modeling and printing. Therefore, UltiMaker PVA provides additional freedom, convenience, and quality throughout the process.

- Reliable adhesion to PLA, Tough PLA, CPE, PETG, and Nylon.

- Non-toxic formula, dissolves in ordinary tap water, which can be safely disposed of.

- 100% biodegradable without hazardous byproducts.

- Good thermal stability. More resistant to degradation compared to other PVA filaments.

UltiMaker PVA Properties

- Melting temperature 163 ºC.

- Water-soluble support material.

- Non-toxic, 100% biodegradable.

- Dissolves in ordinary tap water.

Compatibility

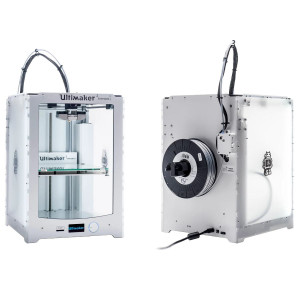

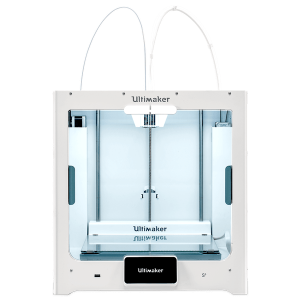

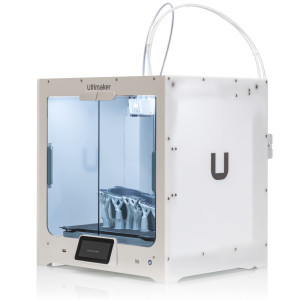

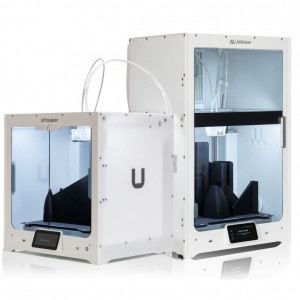

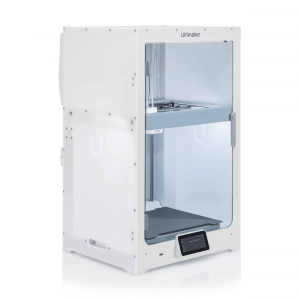

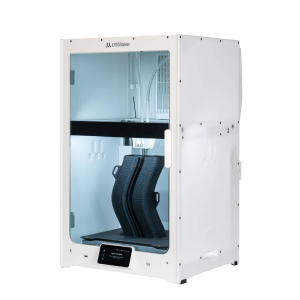

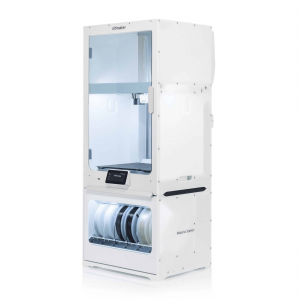

UltiMaker PVA is officially supported by 3D printers in the UltiMaker S5, UltiMaker S3, and UltiMaker 3 series using the BB print core. The material can be used for dual extrusion with the following materials: UltiMaker PLA, UltiMaker Tough PLA, UltiMaker PETG, UltiMaker Nylon, UltiMaker CPE.

UltiMaker PVA Applications

Dual extrusion for printing parts with complex geometries and internal cavities, conceptual models, molds.

- Achieve smoother surface details and complex geometries

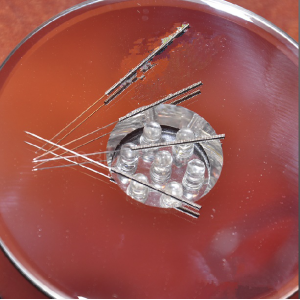

Unlike supports printed with the build material, PVA 3D printing support structures reduce the likelihood of scratches and cuts on detailed surfaces.

- Orient prints for maximum optimization

Printing preparation with PVA gives you the freedom to orient your model in any possible way to optimize its strength or aesthetic properties.

- Unlimited possibilities for mechanical parts

Multi-component applications such as ball bearings, ball and socket joints, and gear mechanisms can be 3D printed as a complete assembly in a single cycle.