- Stock: In Stock

- Product code: 00-00001780

- Shipping Weight: 144.00kg

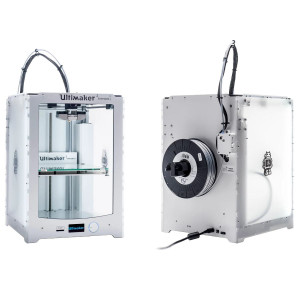

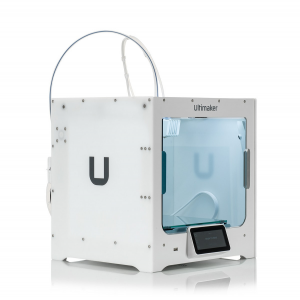

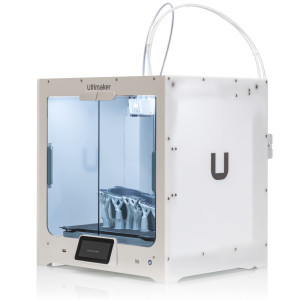

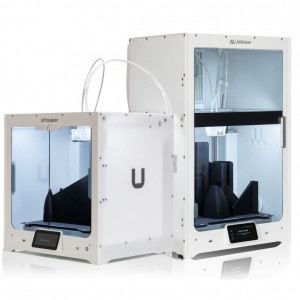

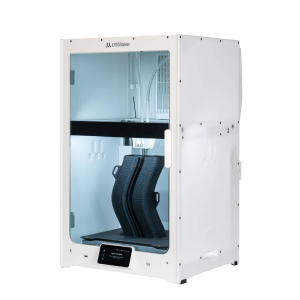

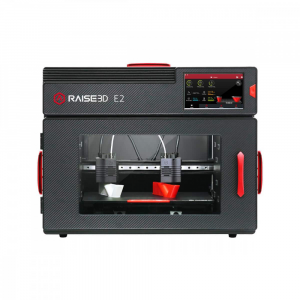

UltiMaker Factor 4 industrial 3D printer

Introducing the UltiMaker Factor 4 3D printer. A new industrial-grade 3D printer offers high reliability, repeatability and performance. Factor 4 technical capabilities will help you optimize your production, simplify your processes and ensure business continuity.

Factor 4 highlights

More than 13 years of experience in innovation, accessibility and openness have resulted in the new UltiMaker Factor 4.

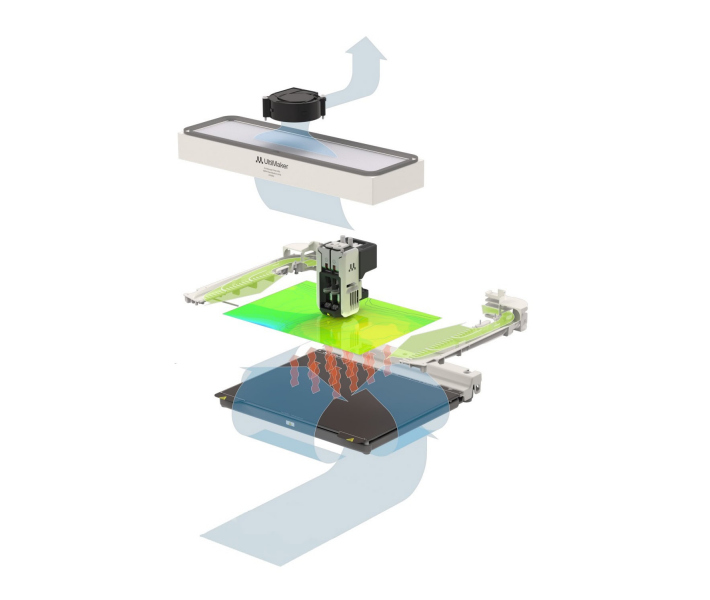

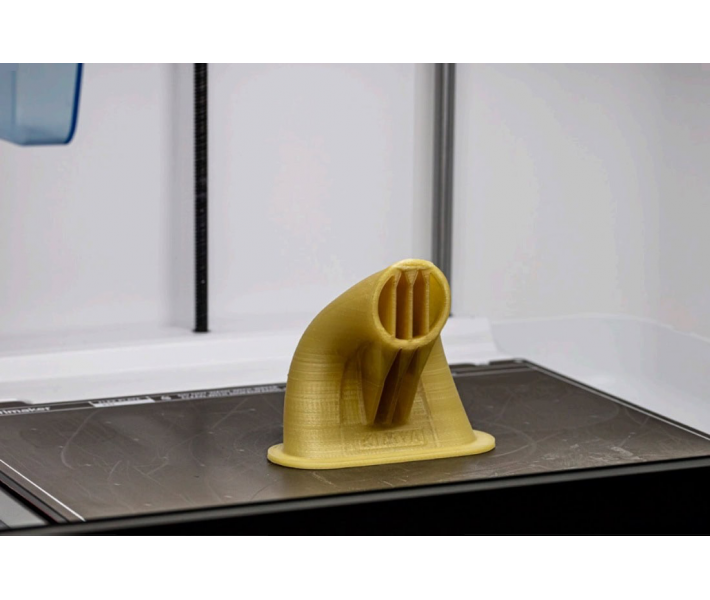

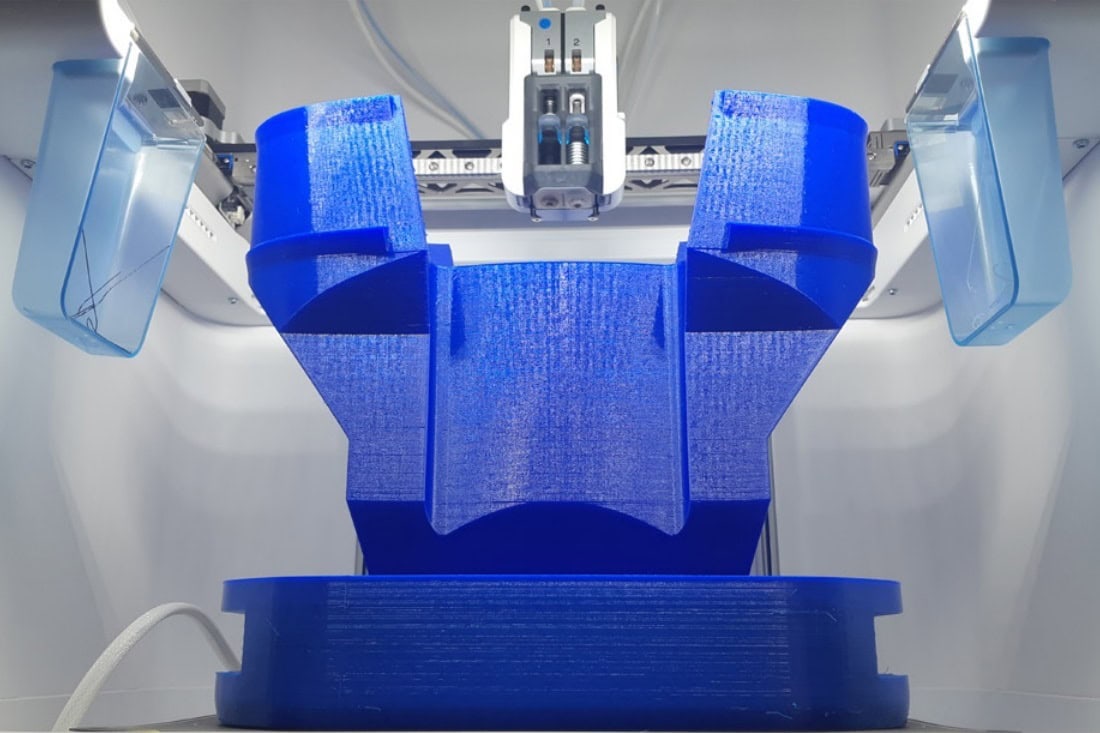

Factor 4 3D printer main benefits include versatility and quality, which means a quick return on investment. This printer improves production with its triple-insulated chamber and direct dual extrusion, as well as an automated material handling system to maintain filament quality.

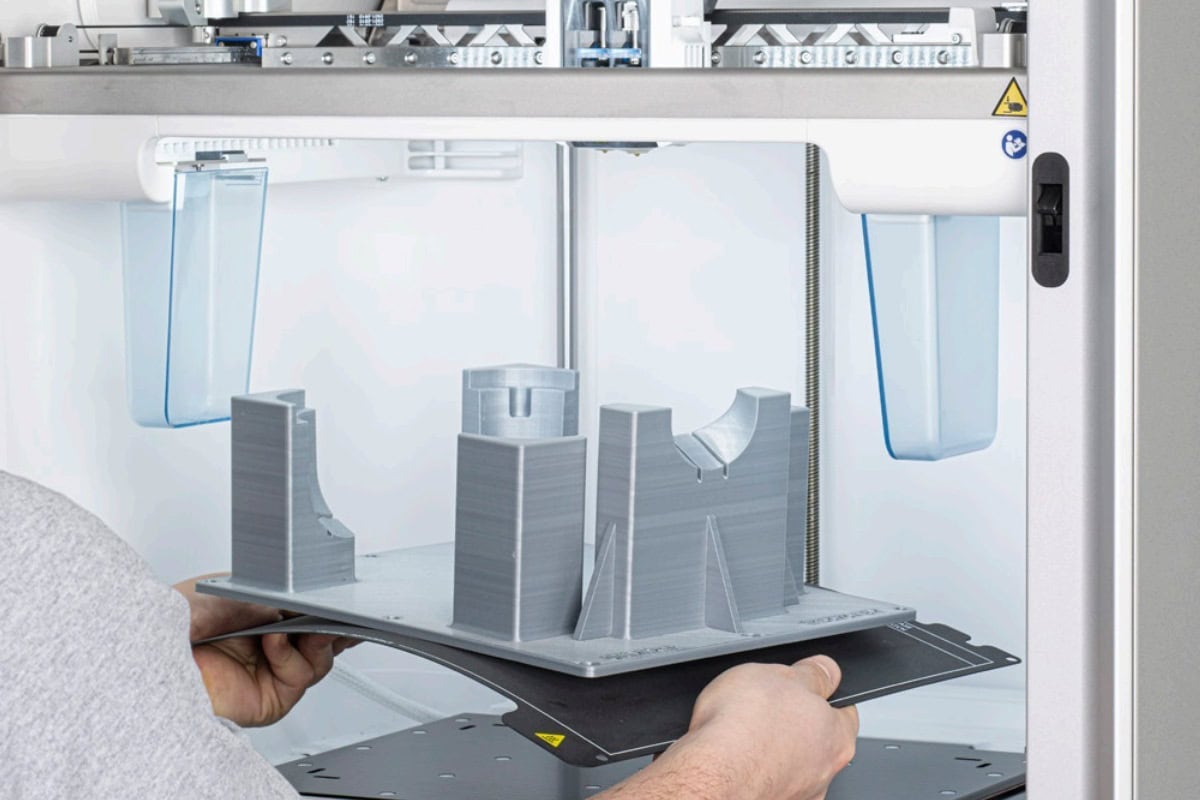

The Factor 4 also delivers high quality results every time, regardless of the size of the project. With built-in technologies, it delivers the highest print accuracy of any UltiMaker printer.

- Designed for industrial production.

- The print volume is 330*240*300 mm.

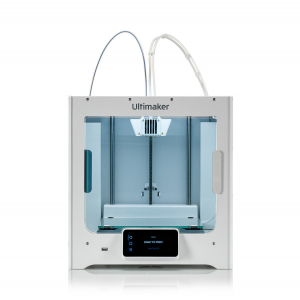

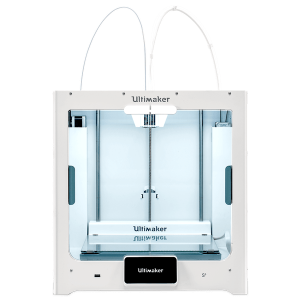

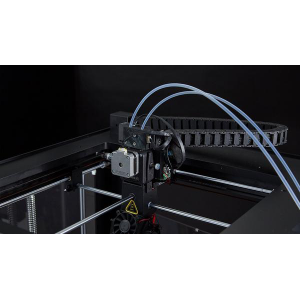

- Double extrusion with direct drive.

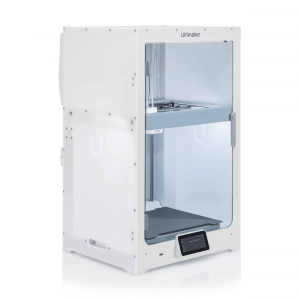

- Actively controlled temperature of the print chamber, chamber with three-layer thermal insulation.

- Reliability, repeatability of results and verification.

- Wide availability of materials: 14+ UltiMaker filaments, open support for 200+ third-party technical materials.

- High temperature printing range up to 340 °C.

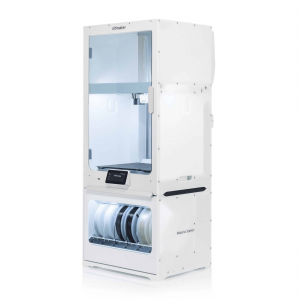

- Automated material supply system with low relative humidity support.

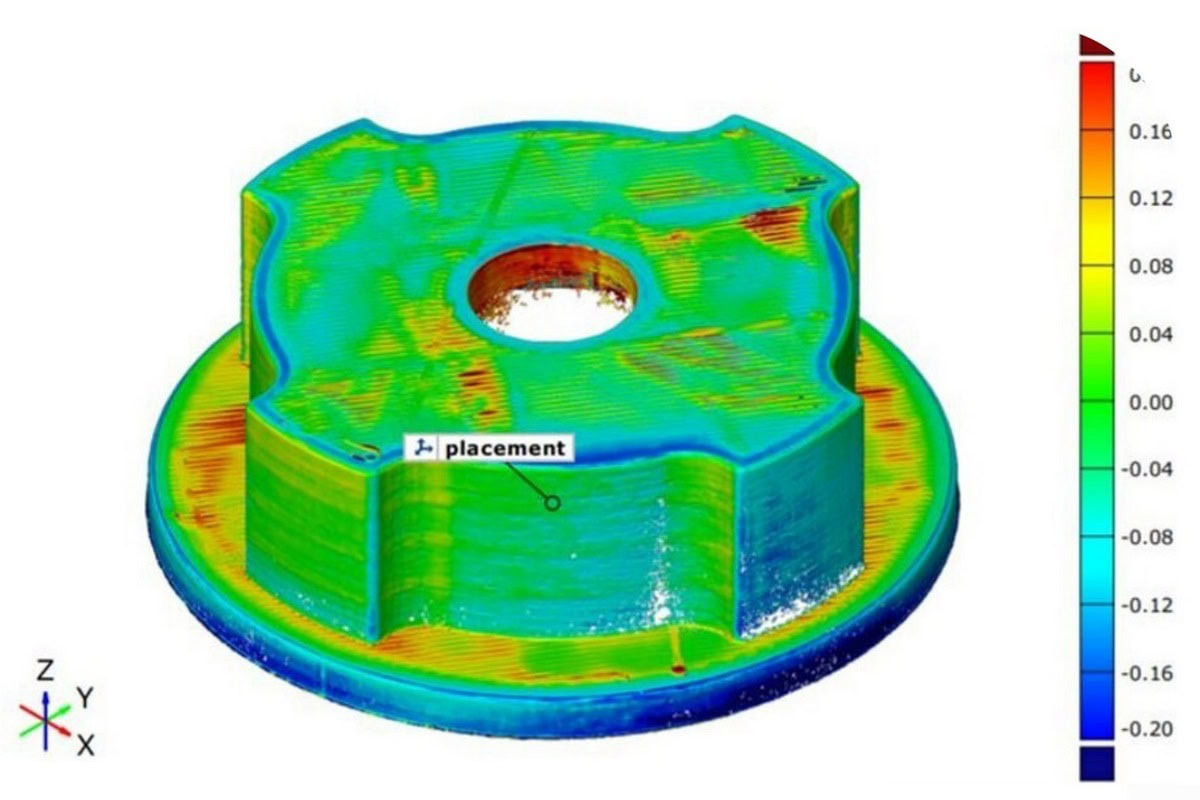

- Built-in print process report.

- An investment in the future – versatility and quality for a fast return on investment.

- Highly modular design for quick and easy repairs.

UltiMaker Factor 4: the next level of industrial 3D printing

The Factor 4 is built for production – it delivers reliability, repeatability and verification with every print. With support for technical materials, direct dual extrusion, and built-in print process reporting, this printer achieves unmatched predictability and minimal variance.

Additionally, the Factor 4 supports direct-drive extrusion for flexible materials, enabling you to quickly transition from highly flexible materials to strong composites. Its rigid H-bridge design and direct-drive printhead enable fast two-material printing with high temperatures of up to 340 °C.

Engineering printing with more than 300 materials

- Extensive material support. 14+ UltiMaker filaments, plus an open platform to support 200+ third-party engineering materials.

- Direct double extrusion. For creating complex parts from a variety of materials: engineering, flexible from TPU 95A to TPU 70A, UltiMaker PLA, Tough PLA, PETG, PET CF, new PPS CF, etc.

- Controlled temperature inside the fully enclosed chamber. Ensures consistent print quality even with high-strength materials.

- High accuracy. ± 0.2 mm or ± 0.2% of the nominal length.

- Low dispersion. < 10% in extrusion speed and mechanical properties.

- Built-in report on the printing process. A detailed report on the deviation of extrusion parameters from the nominal values, their

- location and severity in the 3D model – after each print job. For detailed inspection and quality control.

- Modular design. For easy maintenance and minimal downtime.

- Open system. Compatible with a wide range of materials and software.

- Air purification. Independently tested to remove up to 95% of ultrafine particles for improved air quality.

Factor 4 advantages

- Increased productivity. Increase production speed and efficiency with a dual extruder, utilizing the entire work surface for dual printing.

- Improved quality. Create reliable and repeatable parts.

- Reduced costs. Reduced downtime and material costs.

- Expanded capabilities. Access to a wider range of materials and applications.

- An investment in the future. Modular design and regular updates ensure durability and relevance.

Factor 4 is used for:

- Production of small series of auxiliary components.

- Creation of production tools and fixtures.

- Production of reliable spare parts.

- Development of functional engineering prototypes.

Factor 4 is the perfect choice for:

- Manufacturers looking for a reliable and productive 3D printer for mass production.

- Engineers who design complex parts and need to print with a wide range of materials.

- Research laboratories that need a 3D printer with high accuracy and repeatability.

Interchangeable print cores to match your application and material

UltiMaker print cores feature a quick-change design and an EEPROM chip. They are Cura recognized and can be quickly replaced without tools to meet the requirements of any print job, increasing efficiency and reducing downtime.

| Type | Nozzle diameter | Max. temperature | Materials |

| AA | 0.25, 0.4, 0.8 | 280 °C | For Polyamide 6, TPU, PC, ABS, PETG |

| BB | 0.4, 0.8 | 280 °C | PVA and other water-soluble materials |

| CC | 0.4, 0.6 | 300 °C | Composites, metal |

| DD | 0.4 | 280 °C | Ultrafuse support materials, ceramics |

| HT | 0.6 | 340 °C | High temperature composites, PPS CF, PEKK-A |

Specifications

| Printing technology | FDM |

| Construction field (mm) | 330*240*300 |

| Construction field for double printing (mm) | 330*240*300 |

| Plastic diameter (mm) | 2.85 |

| Number of extruders | 2 |

| Maximum nozzle temperature (°C) | 340 |

| Printing camera type | Closed |

| Camera heating | Yes |

| Plastic drying | Yes |

| Feeding mechanism type | Direct |

| Layer height (micron) | Nozzle 0.25 mm: 150 – 60 / Nozzle 0.4 mm: 200 – 20 / Nozzle 0.6 mm: 300 – 20 / Nozzle 0.8 mm: 600 – 20 |

| Extruder construction type | Replaceable print cores, automatic nozzle lift system and flood detection |

| Nozzle diameter (mm) | 0.25 / 0.4 / 0.6 / 0.8 |

| Positioning accuracy (μm) | XY: 6.9; Z: 2.5 |

| Print accuracy (μm) | 200 |

| Platform heating | Yes |

| Maximum platform temperature (°C) | 120 |

| Material of the platform | Flexible steel plate with PEI coating |

| Supported materials | 14+ UltiMaker materials, 250+ Marketplace materials |

| Operating noise, dB | < 50 |

| Air filter | Replaceable HEPA 13 filter |

| Management | 7″ color touch screen |

| Features | Dual Extruder, Interchangeable Print Cores, Automatic Nozzle Lift System, Flood Detection, Red Stop Button, Open Door Sensor |

| Supported file types | STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG, G, GCODE, GCODE.gz, UFP |

| Software | UltiMaker Cura, UltiMaker Digital Factory. Integration of plugins: SolidWorks, Siemens NX, Autodesk Inventor |

| Connection | Wi-Fi (2.4 and 5 GHz), Ethernet, USB |

| Power requirements | 100-240 V AC, 50-60 Hz, 6A |

| Output power | 600 W |

| System requirements | Windows 7 (64-bit), MacOS X 10.12, OpenGL 2.1, 4 GB RAM (8 GB recommended) |

| Warranty period (months) | 12 |

| Net weight (kg) | 120,0 |

| Weight Brutto (kg) | 137,0 |

| Assembled dimensions (mm) | 695×605×1287 |

| Package dimensions (mm) | 760×800×1587 |

| Working environment temperature range (°C) | 18 – 34 |

| Humidity range of the working Environment (%) | 30 – 70 |

| Storage temperature (°C) | 5 – 40 |