- Stock: In Stock

- Product code: 00-08800243

Ultimaker ABS 3D printer filament

Ultimaker ABS (acrylonitrile-butadiene-styrene) 3D printer filament is an excellent choice for creating functional prototypes and complex end-use parts. It is designed to minimize warping and provide stable interlayer adhesion.

It is an excellent choice for creating functional prototypes and complex end-use parts.

ABS filament can be combined with Breakaway support filaments.

- Good adhesion between layers, especially when printing in a closed print chamber.

- Withstands temperatures up to 85 °C.

- Achieve aesthetic details that rival injection molded parts.

- Double extruded with a choice of 10 ABS colors or with Breakaway support material.

ABS material characteristics

Below are some of the main mechanical properties of ABS from Ultimaker:

- Tensile modulus – 1681.5 MPa.

- Elongation at break – 3.5%.

- Elongation at break – 4.8%.

- Good bending strength – 70.5 MPa.

- Flexural elastic modulus – 2070 MPa.

- High impact strength of Izod – up to 10.5 kJ/m².

- High hardness – Shore 76D.

- High melting point – from 225 °C.

- Vick’s softening point is 97 °C.

- Melting point – 225-245 °C.

Printing parameters

- Nozzle temperature – 225 – 260 °C

- Table temperature – 80 – 90 °C

- Desktop surface – glass + thin layer of glue

- Closed chamber – required

Compatibility

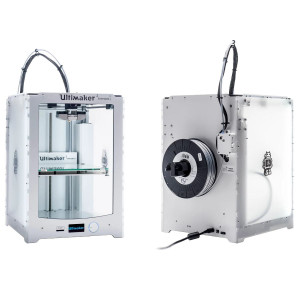

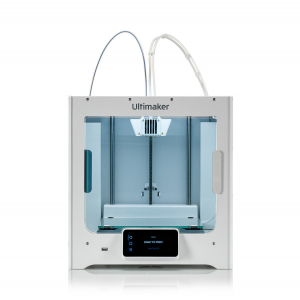

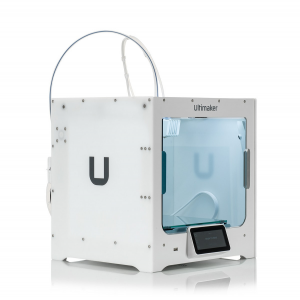

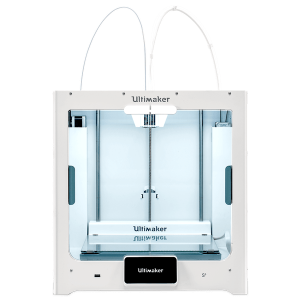

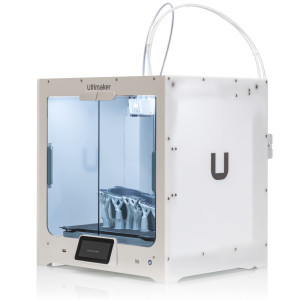

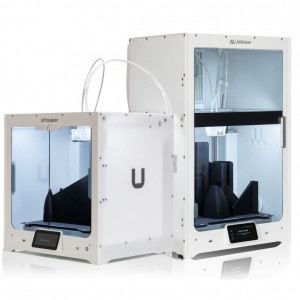

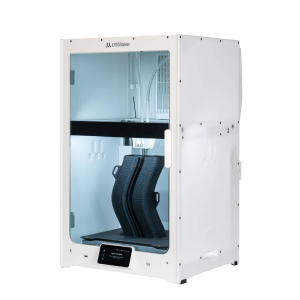

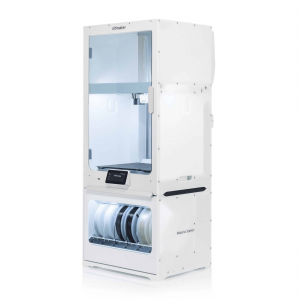

UltiMaker ABS filament can be printed on UltiMaker 3D printers that have a heated build plate, although it will print most reliably on the UltiMaker S Series, UltiMaker 3 and UltiMaker 2+ (Connect) due to the ability to close the printer. To print ABS on the UltiMaker S and 3 Series, you will need an AA print core.

On the UltiMaker S and Ultimaker 3 Series, you can use UltiMaker Breakaway as an ABS support material, and you can also make two-color ABS prints. Other combinations are not supported as ABS does not adhere well to other materials.

Applications

The excellent mechanical properties of ABS filament are perfect for 3D printing in the engineering field for visual and functional prototyping, suitability testing, printing tools, end-use parts, concept models, specialty components, and small batch production.

- Prototype testing

ABS provides engineers with a low-cost approach to development cycles, allowing them to quickly design, print, and test prototypes before going into full production.

- Fit testing

With ABS 3D printing, you can accurately simulate the shape, fit, and operation of the final part, giving you confidence in the final design.

- Multiple possibilities

Go from conceptual design to production in a few days thanks to the ability of ABS yarn to create functional and mechanically robust products.