- Stock: Price on request

- Product code: 123

- Shipping Weight: 40.00kg

- SKU: F-FG-0010

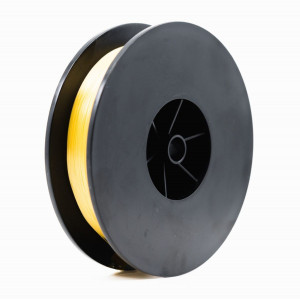

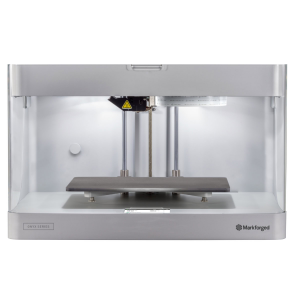

Onyx Kit (10x800cc) for Industrial 3D Printing

This offer is available only to Success Plan customers.

In the world of additive manufacturing, the choice of material determines not only the appearance of the product but also its functional durability. The Onyx spool kit, which includes 10 units of 800 cubic centimeters each, represents a basic building block for the Markforged ecosystem. This set is available exclusively to customers with a valid Success Plan contract, emphasizing the product's focus on uninterrupted professional use on an industrial scale.

Onyx material has revolutionized the industry by combining the stiffness of nylon with the strength of carbon fiber. Using a kit of 10 spools allows enterprises to ensure a stable production cycle, minimize downtime, and optimize logistics costs for the purchase of consumables.

Technical Specifications and Material Properties

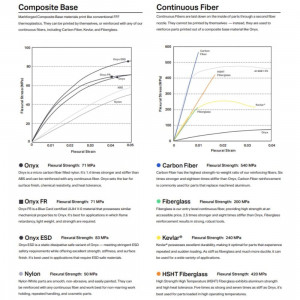

Onyx is a micro-carbon reinforced nylon fiber. Unlike standard thermoplastics, this composite possesses a unique combination of physical and mechanical properties:

- Thermal Resistance: The heat deflection temperature under load is up to 145°C, allowing parts to be used in high-temperature environments.

- Dimensional Stability: Due to the integration of micro-carbon fibers, the material is virtually resistant to deformation (warping) during printing, ensuring tight tolerances.

- Chemical Resistance: Onyx parts are resistant to oils, greases, and common solvents.

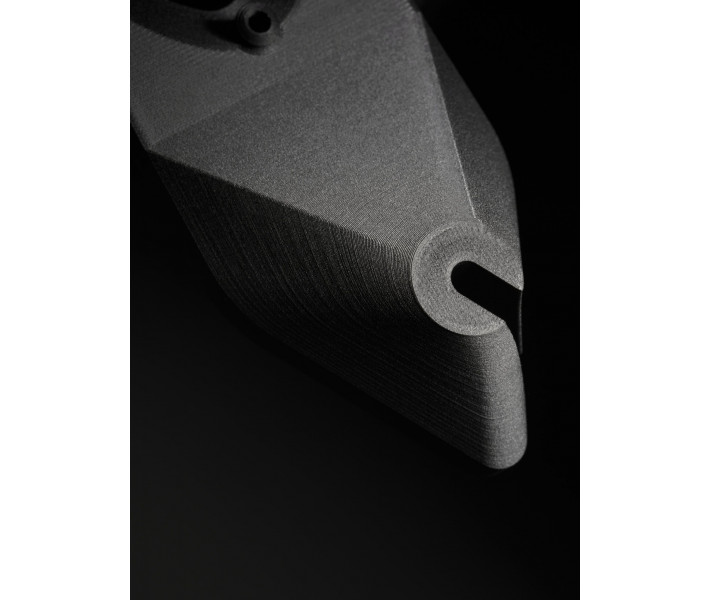

- Surface Quality: The matte black finish hides print layers, giving products the appearance of molded parts that do not require complex finishing.

Each 800 cubic centimeter (cc) spool is carefully vacuum-packed with a desiccant, as the nylon base is hygroscopic. Operating within the Success Plan ensures that you receive fresh batches of material with maximum layer adhesion.

Key Features of the Onyx Kit for Success Plan

The main feature of this offer is scalability. Purchasing a kit of 10 spools is not just about volume; it is an investment in the stability of the workflow.

Perfect Combination with Continuous Fiber

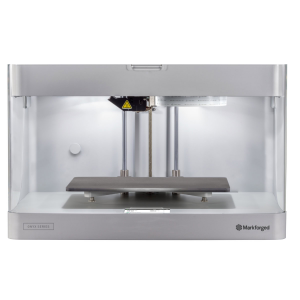

Onyx serves as the primary matrix for Continuous Fiber Reinforcement (CFR) technology. When using Markforged 3D printers (such as the Desktop or Industrial series), continuous fibers of carbon, fiberglass, or Kevlar can be laid inside the Onyx. In such a combination, the strength of the final part can exceed the strength of 6061-T6 aluminum alloy.

Intelligent Print Management

Each spool is equipped with a chip that communicates with the Eiger software. The system automatically tracks the remaining material, recommends optimal print settings, and prevents errors associated with using an incorrect profile.

Advantages of Using a 10-Spool Kit

Switching to bulk kits within a service plan provides the user with several strategic advantages:

- Economic Efficiency: The cost per cubic centimeter of material in the kit is lower than when purchasing individual spools at retail. This reduces the total cost of ownership (TCO) of the equipment.

- Quality Assurance: The Success Plan program provides priority support. Using original Onyx guarantees the preservation of the warranty on print heads and mechanical components of the printer.

- Readiness for Large Projects: With a reserve of 8000 cc of material, the engineering department can launch production of large batches of tooling or oversized prototypes without fear of running out of filament suddenly.

- Result Repeatability: All 10 spools in the kit usually belong to the same production batch, which eliminates even minimal deviations in color shade or physical properties between different parts of the same project.

Applications of Onyx Composite

Due to its characteristics, Onyx parts find application where conventional plastic (PLA or ABS) fails.

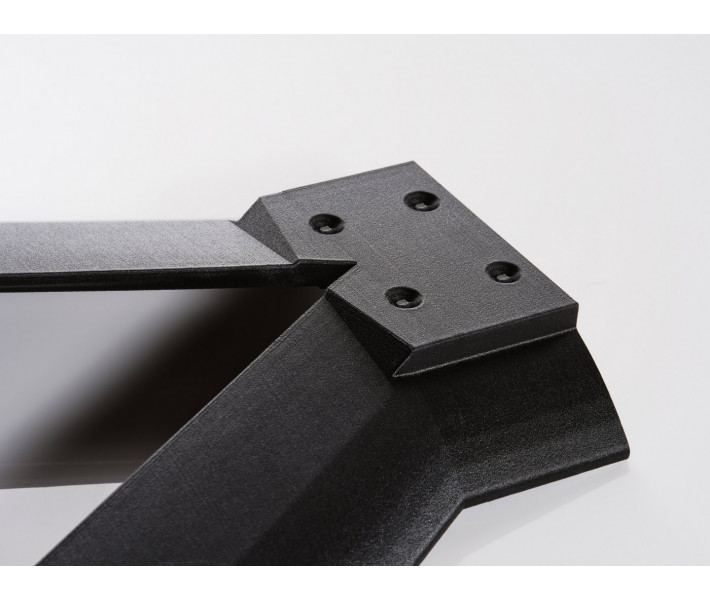

Industrial Tooling and Clamping Devices

This is the primary area of application. Soft jaws for vices, drilling jigs, welding templates, and positioners are printed from Onyx. The material does not scratch the workpieces but withstands significant mechanical loads.

Functional Prototyping

For testing ergonomics and the assembly of complex mechanisms, Onyx is the benchmark. Parts can be tested under real operating conditions by installing them on engines or industrial equipment.

End-Use Part Production

Many companies use Onyx to produce small-batch end-use parts: brackets, sensor housings, air ducts, and interior elements for specialized machinery.

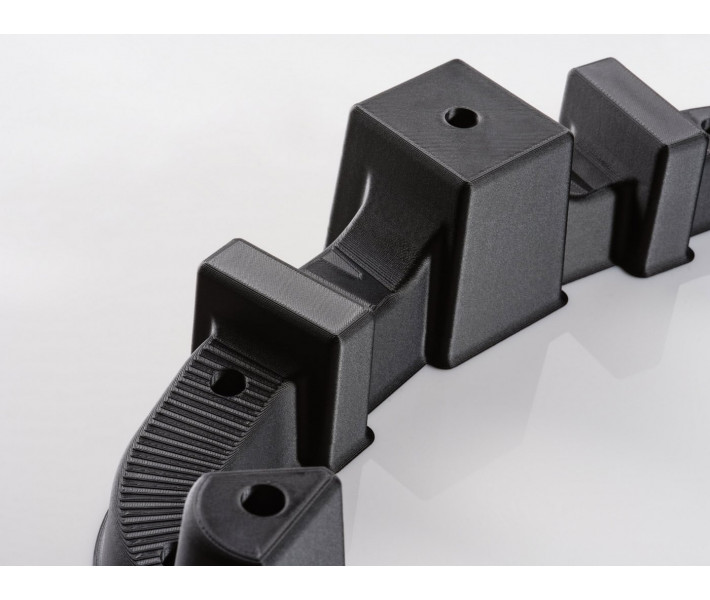

Robotics and Automation

The lightness of the material combined with its stiffness makes it ideal for creating robot end-effectors. Reducing the weight of the tool at the end of the manipulator increases its speed and reduces wear on the drives.

Why Choose Original Markforged Onyx

Choosing the original Onyx kit (10x800cc) is a choice in favor of predictability. Unlike third-party composite filaments, Onyx is designed specifically for the kinematics and temperature regimes of Markforged printers. This eliminates the risk of nozzle clogging and ensures that the strength characteristics set in the Eiger simulator will match the actual performance of the printed part.

Using this kit within the Success Plan is the highest standard of additive manufacturing organization, ensuring maximum return on your investment in 3D technologies. Call us, and we will help you choose materials for 3D printing for any task!

3D Printers

- Metal X

- FX10

- FX20

- X7 (Gen 2)

- X7 (Gen 2) Field Edition

- X7 (Gen 2) Field Edition Brochure

- Mark Two (Gen 2)

- Onyx Pro (Gen 2)

Additional Equipment

Materials

Metal

Markforged Metal Filaments combine the simplicity and safety of FFF printing with the superior properties of advanced metals, bringing metal 3D printing to your benchtop.

- 17-4PH Stainless Steel

- 316L Stainless Steel

- Copper

- H13 Tool Steel

- Inconel 625

- A2 Tool Steel

- D2 Tool Steel

Plastics

Composite Base filaments are engineering-grade materials that print using a conventional FFF (FDM-style) process. Print with them alone or with Continuous Fibers to yield strong parts. The ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries.

Continuous Fiber

Continuous Fibers enable Markforged composite printers to print metal-strength parts. They cannot be used alone — however, when printed with a Composite Base, they form the backbone of a strong printed part.