- Stock: In Stock

- Product code: 00-00012698

- Shipping Weight: 0.60kg

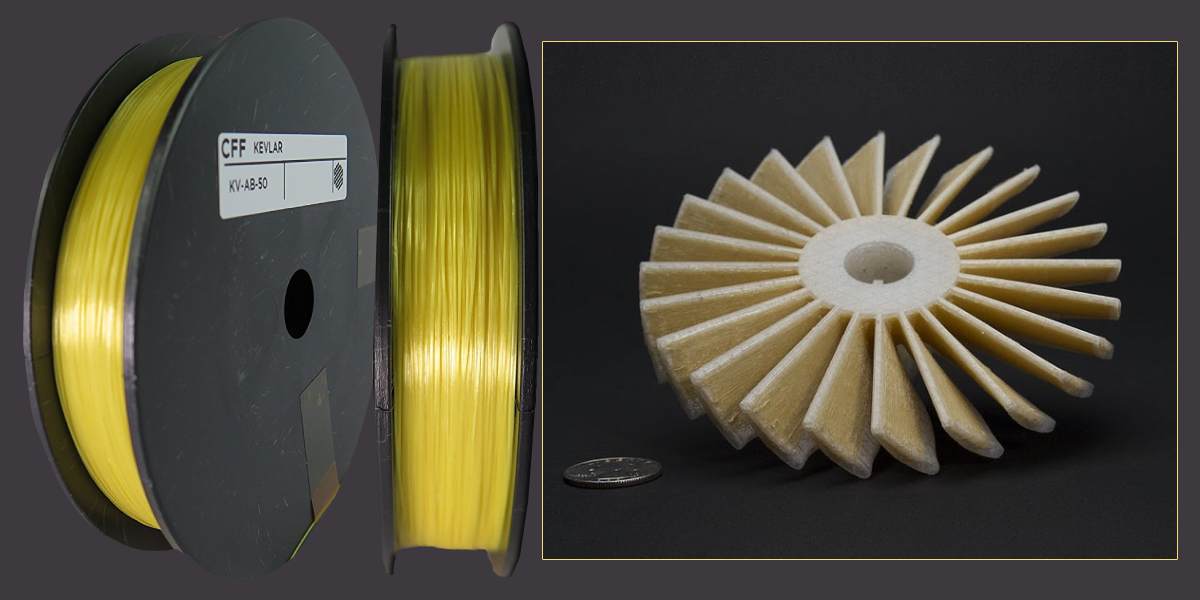

- SKU: KV-AB-50

Markforged Kevlar CFF: Strength and Shock Absorption for High-Stress Parts

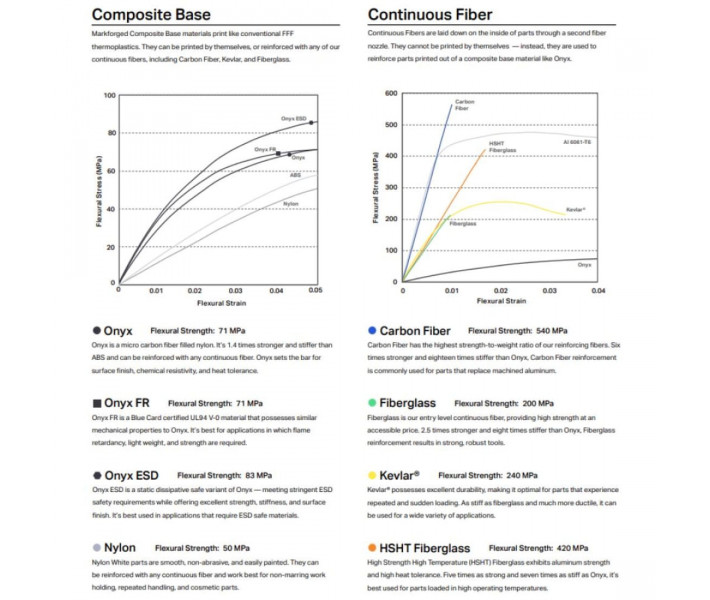

Markforged Kevlar CFF 50cc filament is a highly specialized material designed to reinforce parts 3D printed on Markforged printers using Continuous Fiber Fabrication (CFF) technology. It consists of a continuous aramid fiber based on Kevlar® (DuPont™ Kevlar® fiber). When integrated into a base composite material (such as Onyx), Kevlar imparts outstanding impact resistance and fracture toughness to the final product. The filament is optimal for creating parts operating in demanding conditions, subjected to repetitive or sudden loads.

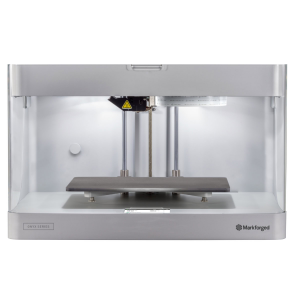

- The material is compatible with the following Markforged 3D printers: Mark Two, X7, FX20

Key Characteristics and Features

- Material Type: Continuous Aramid Fiber (Kevlar®)

- Impact Resistance: Extremely high, best among Markforged fibers

- Wear Resistance: Best among Markforged reinforcing fibers

- Toughness/Flexibility: High, prevents brittle failure

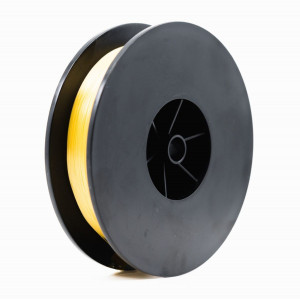

- Format: 50cc (compact, for testing and small parts)

Continuous Aramid Fiber

The main feature is the use of continuous Kevlar® fiber, which is laid along a specified path within the plastic matrix. This ensures even load distribution and prevents brittle failure. Unlike chopped fibers, continuous fiber allows for strength comparable to some metals, at a significantly lower weight.

High Impact Resistance and Toughness

Aramid fiber is known for its ability to absorb impact energy, making it extremely resistant to cracking and catastrophic failure. Parts reinforced with Kevlar CFF can withstand strong and repeated impacts, which is critical for tooling and components operating under dynamic loads. Kevlar is one of the toughest reinforcing fibers offered by Markforged.

Excellent Resistance to Wear and Abrasion

Kevlar® has the best abrasion resistance among all Markforged reinforcing materials. This property makes the filament an ideal choice for manufacturing wear-resistant parts such as guides, stops, or working surfaces subjected to friction.

50cc Composite Plastic Volume

The 50cc spool volume format (50 cubic centimeters) is a compact format that is convenient for: testing new designs or materials; printing small or single critically important parts; controlling and optimizing the consumption of expensive reinforcing material.

Compatibility and Technical Specifications

Material: Continuous Aramid Fiber (Kevlar®). Printing Technology: Continuous Fiber Fabrication (CFF). Spool Volume: 50 cc. Filament Diameter: 1.75 mm (standard for Markforged). Printer Compatibility: Mark Two, X7, FX20 (when used in conjunction with a base material, such as Onyx).

Benefits for Users and Application Areas

The use of Markforged Kevlar CFF 50cc filament opens up broad opportunities for engineers and manufacturing companies who require functional and durable components.

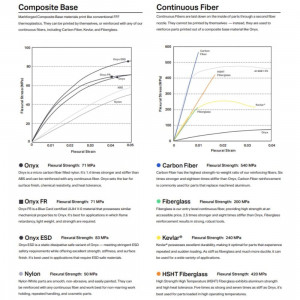

Superiority over Traditional Materials

Parts reinforced with Kevlar CFF demonstrate strength that is many times greater than ordinary thermoplastics (up to 10 times stronger than ABS when used with Onyx). Furthermore, they are significantly lighter than analogous metal parts, which is important for weight reduction in moving mechanisms or in the aerospace industry.

Reliability in Dynamic Conditions

The key advantage for the user is the reliability of the part under conditions of repetitive loads and high impact stresses. Kevlar CFF helps avoid unexpected, brittle failure. This allows for the creation of safer and more durable tools, reducing equipment downtime.

Appropriate Application of Kevlar CF

Kevlar CFF 50cc is ideally suited for areas where strength, resilience, and protection against wear are critical:

- Manufacturing Tooling: end-of-arm tooling for robots subjected to impacts, guides, and stops; Automotive and Aerospace Industry: lightweight yet strong protective housings, panels, components subjected to vibrations and impacts;

- Sports Equipment: elements of protective gear where the ability to absorb energy is important;

- Mechanical Components: parts replacing Delrin® or other plastics where increased wear resistance and shock absorption are required.

Video Review of Markforged Filaments

If you are looking for a material that allows your 3D-printed parts to withstand repeated impacts, high wear, and last longer in the most demanding conditions, Markforged Kevlar CFF 50cc filament is the optimal choice. Add this unique reinforcing filament to your printing arsenal to create truly invulnerable components. Call us – our managers will select the perfect printing material for any task!

3D Printers

- Metal X

- FX10

- FX20

- X7 (Gen 2)

- X7 (Gen 2) Field Edition

- X7 (Gen 2) Field Edition Brochure

- Mark Two (Gen 2)

- Onyx Pro (Gen 2)

Additional Equipment

Materials

Metal

Markforged Metal Filaments combine the simplicity and safety of FFF printing with the superior properties of advanced metals, bringing metal 3D printing to your benchtop.

- 17-4PH Stainless Steel

- 316L Stainless Steel

- Copper

- H13 Tool Steel

- Inconel 625

- A2 Tool Steel

- D2 Tool Steel

Plastics

Composite Base filaments are engineering-grade materials that print using a conventional FFF (FDM-style) process. Print with them alone or with Continuous Fibers to yield strong parts. The ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries.

Continuous Fiber

Continuous Fibers enable Markforged composite printers to print metal-strength parts. They cannot be used alone — however, when printed with a Composite Base, they form the backbone of a strong printed part.