- Stock: In Stock

- Product code: 00-00012697

- Shipping Weight: 1,600.00kg

- SKU: F-FG-0006

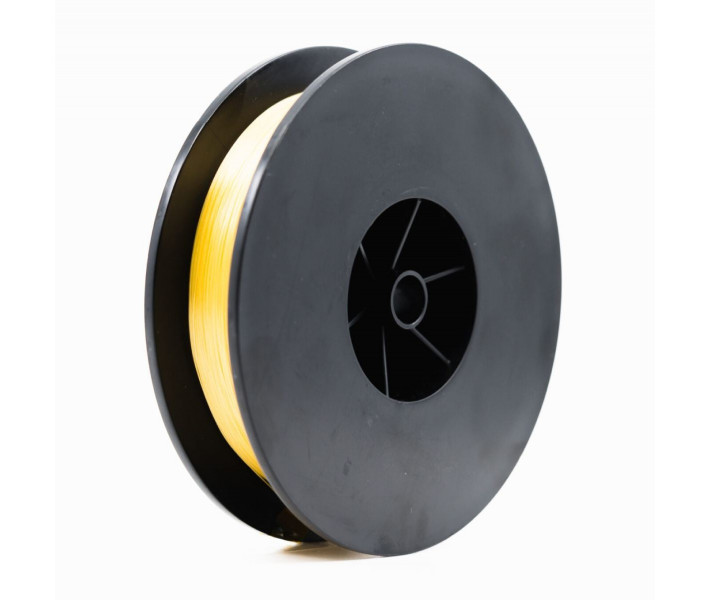

Markforged Fiberglass Kevlar CFF – Lightweight, Impact, Wear, and Warp-Resistant Parts

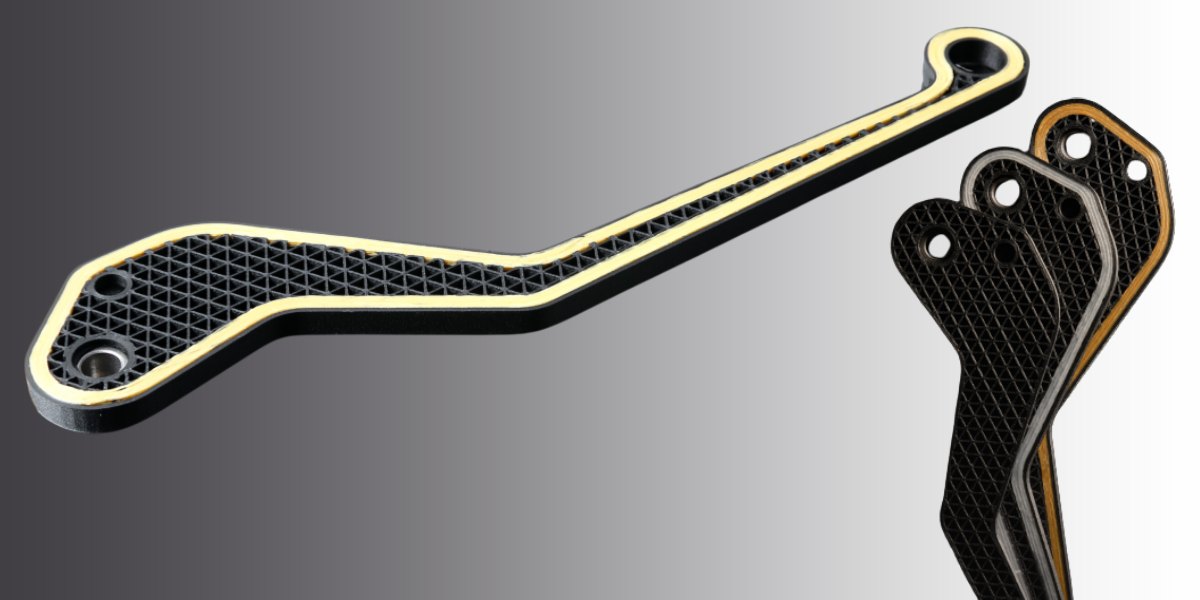

The Fiberglass Kevlar CFF 150cc composite filament is a high-strength composite material specifically designed for the Continuous Filament Fabrication (CFF) technology on Markforged 3D printers. It combines fiberglass and Kevlar, providing exceptional resistance to impact, wear, and warping while maintaining the lightness of the finished parts.

- Fiberglass Kevlar CFF is compatible with the following Markforged 3D printers: Mark Two, X7, FX20

Thanks to its unique fiber structure, the material significantly increases the stiffness, strength, and impact resistance of printed parts, making it an ideal choice for functional prototypes, production tools, housings, fixtures, and components operating under dynamic loads.

Kevlar CFF offers high resilience and excellent resistance to fatigue loads, while fiberglass adds extra stiffness with minimal weight increase. This balance of properties ensures an optimal ratio of strength, flexibility, and durability.

Key Advantages of Kevlar CFF

- Maximum Strength — continuous reinforcement with Kevlar and fiberglass to create parts comparable in characteristics to metal.

- High Impact Resistance — ideal for items subjected to vibrations and shock loads.

- Lightweight — strong yet light components for engineering tasks.

- Resistance to Wear and Fatigue — the material maintains its shape and functionality even during prolonged use.

- Compatibility with Markforged Mark Two, X7 series 3D printers and other CFF-supported devices.

Main Characteristics of Kevlar CFF from Markforged

- Material Type: Continuous Composite Fiber (CFF)

- Base: Kevlar + Fiberglass

- Volume: 150 cc

- Purpose: part reinforcement, increased strength and stiffness

- Application: industrial manufacturing, prototyping, mechanical components, assembly tools, and tooling

Who is Fiberglass Kevlar CFF Suitable For

- The material will be especially useful for:

- engineers and manufacturing companies;

- developers of functional prototypes;

- service centers working with load-bearing components;

- manufacturers of tooling and fastening elements.

Video about Markforged Filaments

By choosing Markforged Fiberglass Kevlar CFF 150cc, you get not just a filament, but a high-tech composite that creates parts with outstanding impact resistance, wear resistance, and minimal mass. The unique structure of Kevlar reinforcement provides an optimal balance of flexibility and strength, making the material ideal for functional prototypes and critical assemblies.

Buying Kevlar from the official Markforged representative in Ukraine means guaranteed access to original certified material, stable print quality, technical support, and confidence that every spool meets the manufacturer's strict standards. Choose reliability, choose the official source.

3D Printers

- Metal X

- FX10

- FX20

- X7 (Gen 2)

- X7 (Gen 2) Field Edition

- X7 (Gen 2) Field Edition Brochure

- Mark Two (Gen 2)

- Onyx Pro (Gen 2)

Additional Equipment

Materials

Metal

Markforged Metal Filaments combine the simplicity and safety of FFF printing with the superior properties of advanced metals, bringing metal 3D printing to your benchtop.

- 17-4PH Stainless Steel

- 316L Stainless Steel

- Copper

- H13 Tool Steel

- Inconel 625

- A2 Tool Steel

- D2 Tool Steel

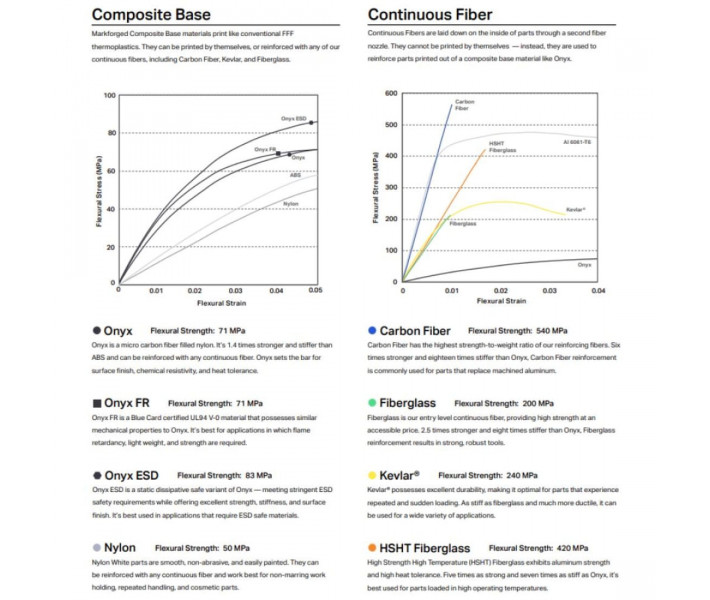

Plastics

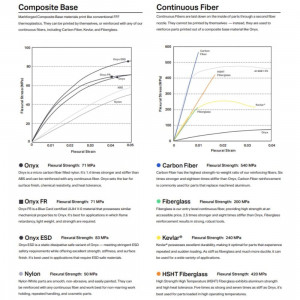

Composite Base filaments are engineering-grade materials that print using a conventional FFF (FDM-style) process. Print with them alone or with Continuous Fibers to yield strong parts. The ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries.

Continuous Fiber

Continuous Fibers enable Markforged composite printers to print metal-strength parts. They cannot be used alone — however, when printed with a Composite Base, they form the backbone of a strong printed part.