- Stock: In Stock

- Product code: 00-00013296

- Shipping Weight: 2.60kg

- SKU: F-MF-1005

Markforged Inconel 625 Filament – Superalloy for Extreme Conditions

Markforged Inconel 625 filament is a high-tech material based on nickel and chromium, designed to work in the most challenging environments. It combines exceptional corrosion resistance with high strength at elevated temperatures, making it indispensable for industrial applications.

This corrosion-resistant Markforged filament meets the chemical requirements of ASTM B443 and retains a tensile strength of 500 MPa even at 600 °C. The delivery format is a 200cc Inconel 625 spool, compatible with Metal X 3D printers.

Why Choose Nickel Superalloy Inconel 625?

In traditional manufacturing, this material is difficult and expensive to process, but thanks to 3D printing technology with superalloys using the Metal X system, you can produce complex geometric parts faster and at lower costs.

Main Advantages:

- resistance to aggressive environments (acids, seawater, chemical compounds)

- retention of strength at extreme temperatures

- ability to manufacture functional prototypes and finished parts

- ease of printing with high quality of the final result

Technical Specifications

Markforged Inconel 625 filament provides a balance between durability and machinability:

- tensile strength at 600 °C – 500 MPa

- compatibility – Inconel 625 for Metal X

- format – 200 cc (1 spool)

- compliance with ASTM B443 standard

This makes the material ideal for components that operate under high temperature and chemical exposure conditions.

Applications

The material for high-temperature 3D printing Inconel 625 is chosen for parts that must withstand loads in extreme conditions. It is used in the production of:

- high-temperature fasteners

- corrosion-resistant fittings

- crucibles

- turbine components

- industrial equipment for the chemical and oil and gas industries

This material is also actively used in aerospace engineering, energy, and the marine industry.

Why Choose Inconel 625 for 3D Printing?

Unlike traditional metals, the nickel superalloy Inconel 625 combines high strength, elasticity, and exceptional resistance to thermal and chemical effects. It is ideal for elements operating in aggressive environments and requiring durability.

Thanks to 3D printing, parts with complex geometries become accessible for rapid prototyping and mass production.

3D Printing with Superalloys – An Advantage for Industry

Using Inconel 625 for Metal X significantly reduces the costs of manufacturing complex metal components. Combined with additive manufacturing technology, this solution provides:

- flexibility in design and manufacturing

- reduced production time

- decreased waste

- ability to adapt production to specific tasks

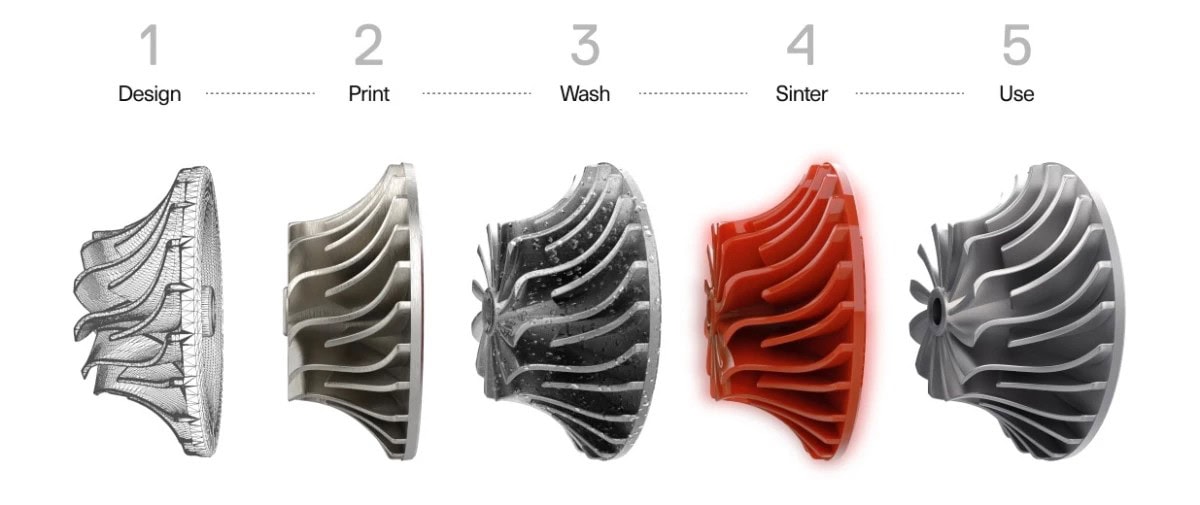

ADAM Manufacturing Technology

The process of manufacturing parts from this material is based on ADAM (Atomic Diffusion Additive Manufacturing) technology. The essence of the technology is that stainless steel powder is contained in a polymer binder, which is fed into the nozzle based on the principle of classic FDM printing. The subsequent sintering process leads to atomic diffusion, resulting in a fully metallic part with excellent mechanical properties.

Buy Markforged Nickel Alloy Filament in Ukraine

By purchasing Inconel 625 200cc Markforged at 3DDevice, you receive a guarantee of an original product from the official representative in Ukraine. We have been working in the field of additive technologies for over 10 years, providing professional consultations and assistance in selecting materials for specific tasks and budgets. By collaborating with us, you gain confidence in the result and support from experts.

3D Printers

- Metal X

- FX10

- FX20

- X7 (Gen 2)

- X7 (Gen 2) Field Edition

- X7 (Gen 2) Field Edition Brochure

- Mark Two (Gen 2)

- Onyx Pro (Gen 2)

Additional Equipment

Materials

Metal

Markforged Metal Filaments combine the simplicity and safety of FFF printing with the superior properties of advanced metals, bringing metal 3D printing to your benchtop.

- 17-4PH Stainless Steel

- 316L Stainless Steel

- Copper

- H13 Tool Steel

- Inconel 625

- A2 Tool Steel

- D2 Tool Steel

Plastics

Composite Base filaments are engineering-grade materials that print using a conventional FFF (FDM-style) process. Print with them alone or with Continuous Fibers to yield strong parts. The ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries.

Continuous Fiber

Continuous Fibers enable Markforged composite printers to print metal-strength parts. They cannot be used alone — however, when printed with a Composite Base, they form the backbone of a strong printed part.