- Stock: In Stock

- Product code: 00-00013272

- Shipping Weight: 0.60kg

- SKU: F-FG-0002

Fiberglass High Temp CFF 50cc – Reinforcing Material

Markforged Fiberglass High Temp CFF 50cc is an engineering reinforcing filament created specifically to strengthen composite parts printed using Continuous Fiber Fabrication (CFF) technology. The material is used in Markforged Industrial Series systems and allows for the manufacture of components resistant to prolonged thermal loads, mechanical stress, and deformation at elevated operating temperatures.

- Compatible with Markforged 3D printers: Mark Two, X7, FX20

The high-temperature fiberglass provides a significant increase in stiffness and strength without a substantial increase in mass, making it an effective solution for designing functional products—from industrial tooling to protective mechanical elements and parts operating in heated environments.

Purpose and Key Properties of Markforged High Temp Fiberglass Filament

This reinforcing material is intended for tasks requiring stable geometry, minimal creep, and the ability to withstand thermal cycles without structural degradation. The filament performs effectively in such conditions due to high heat resistance and resistance to mechanical loads during prolonged operation.

Key Features:

- Increased heat resistance — reinforced parts retain their shape and do not soften when exposed to high temperatures.

- High elastic modulus — finished products can withstand significant loads, replacing aluminum or polymer elements.

- Low thermal deformation — minimal risk of geometry change during operation in manufacturing and laboratory environments.

- Compatibility with CFF technology — reinforcement creates a strong internal structure without losing printing accuracy.

- Optimal mass-to-strength ratio — ability to reduce product weight without compromising operational properties.

Application Areas of Markforged High-Temperature Fiberglass

Engineers and technologists use Fiberglass High Temp CFF in cases requiring a combination of reliability, durability, and heat resistance. The reinforcing material is suitable for:

- manufacturing fixtures, templates, and tools that contact heated surfaces;

- creating heat-resistant industrial tooling and measuring elements;

- manufacturing mechanically loaded parts operating under vibration or cyclic loads;

- producing components for transport, electrical engineering, and instrumentation applications;

- designing functional prototypes with required temperature stability;

- replacing aluminum or metal-polymer parts when a reduction in product mass is necessary.

Compatibility and Usage Features

Markforged Fiberglass High Temp CFF 50cc filament is designed for use with Markforged industrial 3D printers equipped with a continuous reinforcement system. The material is used in conjunction with heat-resistant base polymers and ensures the formation of reinforcing layers with high interlayer adhesion.

Usage Features:

- Compatible with Markforged Industrial Series composite printers.

- Used as a continuous reinforcing fiber.

- Does not require additional post-processing, apart from the standard finishing stage.

- Optimal for serial production of functional parts.

Package Contents

1 spool of Markforged Fiberglass High Temp CFF reinforcing filament, 50 cc volume.

Technical Specifications and Mechanical Properties

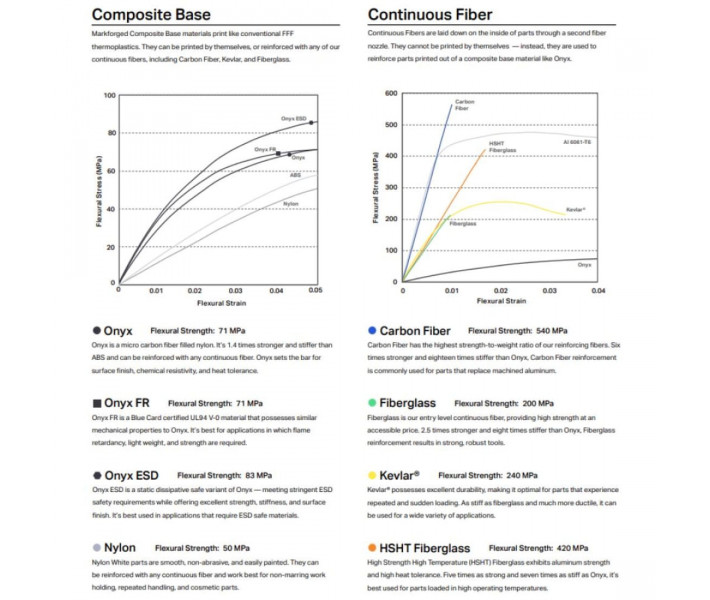

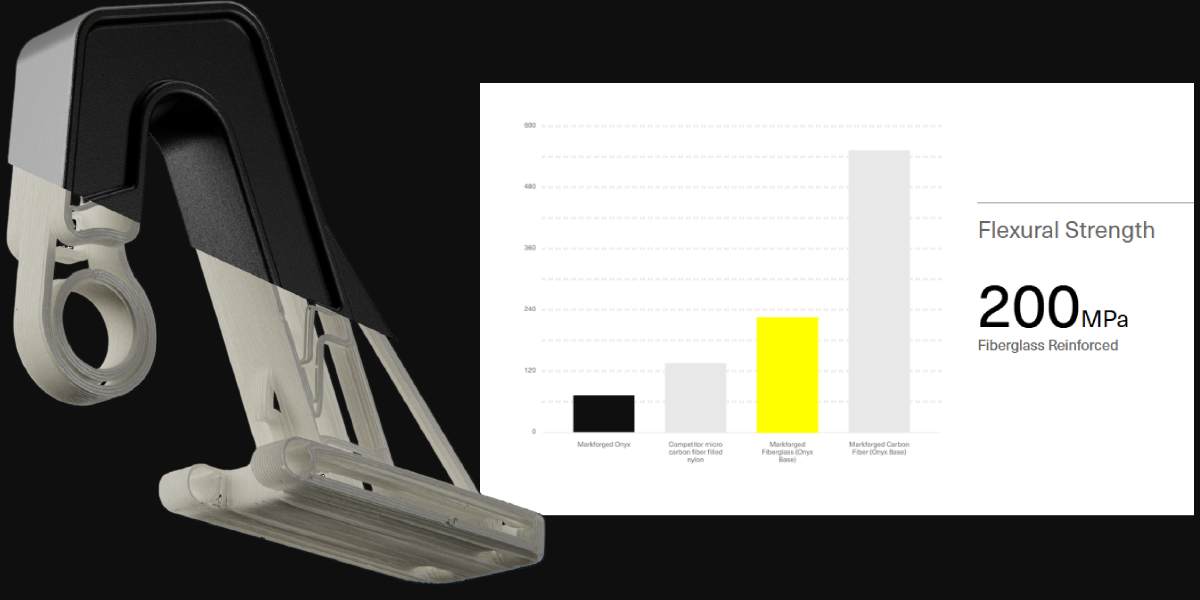

HSHT Fiberglass provides parts with mechanical properties that approach aluminum alloys, but with the advantage of weight and ease of manufacturing.

| Characteristic | Value | Comparison |

| Strength and Stiffness | Up to 5 times stronger and up to 7 times stiffer | Then parts printed only from Onyx (without reinforcement) |

| Flexural Modulus (Stiffness) | 21 GPA | |

| Flexural Strength | 420 MPA | |

| Spool Format | 50 cc |

Why Engineers Choose Markforged Fiberglass High Temp CFF

This material provides the most stable structure within a composite part and allows for characteristics comparable to traditional industrial materials. Engineers value it for:

- Stability under prolonged temperature exposure.

- High stiffness with minimal mass.

- The ability to manufacture strong elements without metalworking.

- Predictable behavior throughout the entire cycle of part creation and use.

- Broad integration into manufacturing processes.

Video about Markforged Filaments

Finished parts reinforced with Markforged Fiberglass High Temp CFF 50cc demonstrate stability, reliability, and high performance even in the most demanding engineering tasks. If you require a composite material that will ensure confident results and withstand real working loads, then High Temp CFF will be the optimal choice. To implement its capabilities in your projects and elevate the quality of printing to a new level, simply place an order — and evaluate the benefits of professional composite reinforcement in your very next project!

3D Printers

- Metal X

- FX10

- FX20

- X7 (Gen 2)

- X7 (Gen 2) Field Edition

- X7 (Gen 2) Field Edition Brochure

- Mark Two (Gen 2)

- Onyx Pro (Gen 2)

Additional Equipment

Materials

Metal

Markforged Metal Filaments combine the simplicity and safety of FFF printing with the superior properties of advanced metals, bringing metal 3D printing to your benchtop.

- 17-4PH Stainless Steel

- 316L Stainless Steel

- Copper

- H13 Tool Steel

- Inconel 625

- A2 Tool Steel

- D2 Tool Steel

Plastics

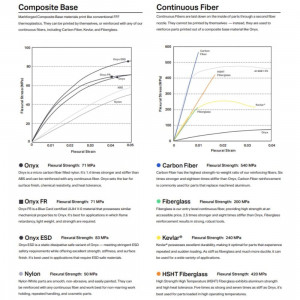

Composite Base filaments are engineering-grade materials that print using a conventional FFF (FDM-style) process. Print with them alone or with Continuous Fibers to yield strong parts. The ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries.

Continuous Fiber

Continuous Fibers enable Markforged composite printers to print metal-strength parts. They cannot be used alone — however, when printed with a Composite Base, they form the backbone of a strong printed part.