- Stock: In Stock

- Product code: 14028-00012692

- Shipping Weight: 1,600.00kg

Fiberglass High Temp (HSHT) – Continuous Fiberglass 3D Printing

Markforged High Temp Fiberglass (HSHT) is a high-strength, high-temperature continuous fiberglass created for Continuous Fiber Fabrication (CFF) technology on Markforged 3D printers.

The material allows the creation of composite parts that can withstand significant mechanical loads at elevated temperatures – where standard polymers and conventional fiberglass already lose stiffness and fail.

Compatible with the following 3D printers Markforged: Mark Two, X7, FX20.

Important to know! Not a standalone filament: HSHT Fiberglass is not a standalone filament, but a continuous reinforcing fiber for 3D printing durable, high-temperature-resistant parts. It is embedded within the layers of the model, dramatically strengthening the base plastic material.

Key Advantages

The HSHT prefix (High Strength High Temperature) clearly defines its purpose: the material maintains strength and stiffness in conditions where most plastic and composite parts soften and deform.

- Operating temperature: up to 105 °C.

- Heat Deflection Temperature (HDT): up to 140 °C.

- Thus, HSHT fiberglass is the optimal choice for critical parts operating near heat sources or under load in a high-temperature environment.

Technical Specifications and Mechanical Properties

HSHT Fiberglass provides parts with mechanical properties that approach aluminum alloys, but with the advantage of lighter weight and ease of manufacturing.

| Characteristic | Value | Comparison |

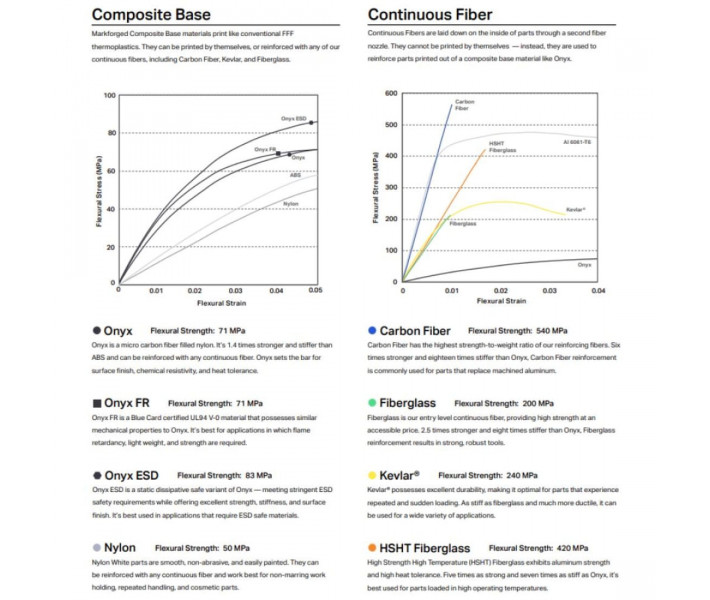

| Strength and Stiffness | Up to 5 times stronger and up to 7 times stiffer | Than parts printed only from Onyx (without reinforcement) |

| Flexural Modulus (Stiffness) | 21 GPa | |

| Flexural Strength | 420 MPa | |

| Spool Format | 150 cc |

Applications and Use Cases

Usage: used exclusively as a reinforcing layer, in conjunction with Markforged composite materials (Onyx, Nylon).

HSHT Fiberglass material is ideal for creating:

- Parts subjected to constant exposure to elevated temperatures.

- Production tooling and fixtures that come into contact with heated surfaces.

- Critical functional elements requiring high dimensional stability and stiffness.

- Tools and tooling operating under conditions of simultaneous load and heat.

- Prototypes and serial products that require the mechanical properties of aluminum, but with lower weight and better cost.

Compatibility: supported exclusively by Markforged 3D printers with CFF technology.

Video about Markforged Filaments

Markforged Fiberglass High Temp CFF 150cc filament is not just a consumable, but a strategic component for creating high-strength, heat-resistant, and lightweight parts. Its unique combination of fire resistance, high flexural strength, and excellent dimensional stability guarantees the durability and reliability of your 3D-printed components, surpassing the characteristics of standard plastics.

By purchasing Markforged Fiberglass High Temp CFF 150cc from the official Markforged representative in Ukraine, you receive not only a guaranteed original product of the highest quality, but also a full range of expert support. This includes professional consultations on application, print setup, and integration of the material into your manufacturing processes, which ultimately ensures the maximum efficiency of your investments in advanced composite 3D printing technologies.

3D Printers

- Metal X

- FX10

- FX20

- X7 (Gen 2)

- X7 (Gen 2) Field Edition

- X7 (Gen 2) Field Edition Brochure

- Mark Two (Gen 2)

- Onyx Pro (Gen 2)

Additional Equipment

Materials

Metal

Markforged Metal Filaments combine the simplicity and safety of FFF printing with the superior properties of advanced metals, bringing metal 3D printing to your benchtop.

- 17-4PH Stainless Steel

- 316L Stainless Steel

- Copper

- H13 Tool Steel

- Inconel 625

- A2 Tool Steel

- D2 Tool Steel

Plastics

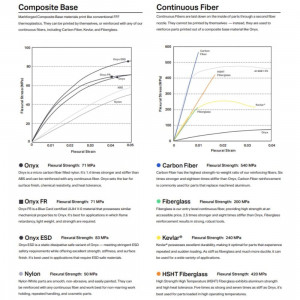

Composite Base filaments are engineering-grade materials that print using a conventional FFF (FDM-style) process. Print with them alone or with Continuous Fibers to yield strong parts. The ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries.

Continuous Fiber

Continuous Fibers enable Markforged composite printers to print metal-strength parts. They cannot be used alone — however, when printed with a Composite Base, they form the backbone of a strong printed part.