- Stock: In Stock

- Product code: 00-00012692

- Shipping Weight: 1,600.00kg

- SKU: F-FG-0003

Markforged Fiberglass CFF – High-Strength Dielectric Filament

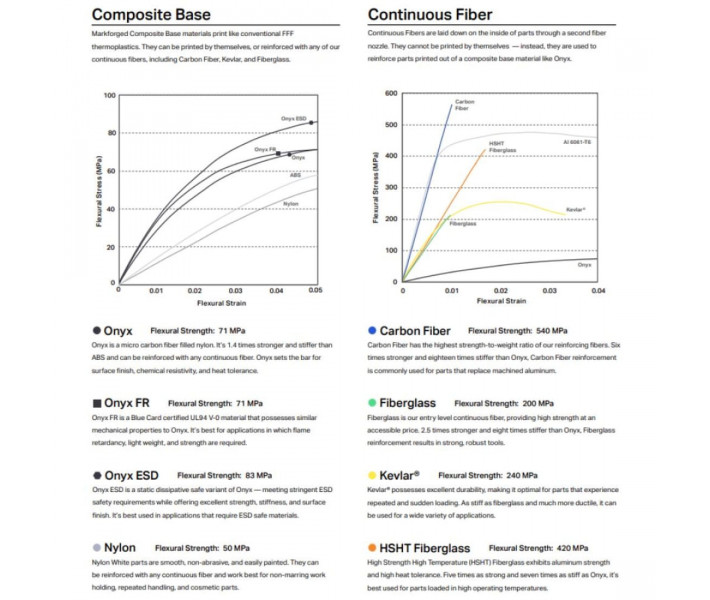

Markforged Fiberglass CFF 150cc (Continuous Fiber Fabrication) filament is a critical material for creating high-strength, reinforced composite parts on Markforged 3D printers. This material is a continuous fiberglass that is used in combination with thermoplastics (Onyx, Nylon) to enhance the mechanical properties of finished products. It is designed for users who require increased stiffness, strength, and impact resistance of parts while needing to maintain dielectric properties.

Fiberglass CFF 150cc is compatible with the following Markforged 3D printers: Onyx Pro, X5, Mark Two, X7

The use of fiberglass allows for the creation of parts that can rival aluminum in terms of strength characteristics, yet possess less weight and do not conduct electricity. This makes the material ideal for functional prototyping and manufacturing final, load-bearing parts. Markforged Fiberglass CFF filament is a continuous, not chopped, fiber, which ensures maximum strength.

Fiberglass CFF Characteristics

| Characteristic | Value/Description |

| Material Type | Continuous Fiberglass |

| Volume | 150 cm³ |

| Printers | Compatible with Mark Two, Onyx Pro, X5, X7 models |

| Flexural Stiffness | Reaches up to 22 GPa when used in a composite |

| Key Properties | High strength, stiffness, impact resistance, dielectric properties |

Key Advantages

Improvement of Mechanical Properties

The main advantage of Fiberglass CFF is the reinforcement of the plastic matrix.

- Increased Tensile Strength and Stiffness: Fiberglass-reinforced parts demonstrate much higher strength and stiffness metrics compared to parts printed only from thermoplastic (e.g., Onyx).

- Impact Resistance: Fiberglass effectively absorbs impact energy, making parts more resistant to brittle fracture.

- Dimensional Stability: Reinforcement helps to reduce thermal deformation and shrinkage during the printing process, ensuring high accuracy of finished products.

Dielectric Properties

Unlike carbon fiber, fiberglass is an electrical insulator. This is critically important for electronic and electrical components where current conduction is unacceptable.

Cost-Effectiveness

Fiberglass is a more accessible material for reinforcement compared to Kevlar or carbon fiber. This allows for cost optimization when high strength is required, but the extreme stiffness of carbon fiber is not mandatory.

CFF Technology and Operational Features

Continuous Fiber Fabrication (CFF) Technology

- The filament is used within the patented Continuous Fiber Fabrication (CFF) technology, available only on Markforged 3D printers. Printing occurs through two extrusion heads: one for the thermoplastic matrix (Onyx), and the second for laying down the continuous fiber.

- Strategic Reinforcement: The engineer can selectively reinforce only those layers and sections of the part where maximum strength is required, which allows for material savings and weight control.

- Quality Control: The filament is supplied in special cartridges that ensure airtight storage and automatic feeding, guaranteeing optimal print quality.

Ideal Combination with Onyx

Fiberglass is most often printed in a matrix of Markforged Onyx (nylon reinforced with chopped carbon fiber). This combination creates a high-quality composite where Onyx provides excellent surface finish and chemical resistance, and fiberglass provides structural integrity.

Areas of Use

Mechanical Engineering and Manufacturing

- Jigs and fixtures: Manufacturing of elements requiring high stiffness and resistance to mechanical stress, but which do not conduct electricity.

- Moderately loaded parts: Creation of brackets, housings, and other functional components requiring reliability and durability.

Electronics and Robotics

- Housings and insulators: printing protective casings for electronic components where electrical insulation and strength are critically important.

- Holders and mounts: manufacturing elements for robots and automated systems that must be strong, light, and not interfere with electronics.

Automotive Industry

- Functional prototypes: Creation of prototypes of parts that require a realistic assessment of mechanical performance.

- Tools and fixtures: Printing assembly tools and measuring templates used on assembly lines.

Markforged Fiberglass CFF 150cc filament is the optimal choice for engineers and manufacturers who need to obtain strong, stiff, and impact-resistant composite parts with essential dielectric properties. By using it on Markforged printers, users quickly create functional tools and final products that demonstrate superior mechanical characteristics at a cost-effective price.

Do you want to order a dielectric filament in Kyiv from an official Markforged representative? You are at the right place: we have original products, and direct deliveries guarantee favorable prices – call us!

3D Printers

- Metal X

- FX10

- FX20

- X7 (Gen 2)

- X7 (Gen 2) Field Edition

- X7 (Gen 2) Field Edition Brochure

- Mark Two (Gen 2)

- Onyx Pro (Gen 2)

Additional Equipment

Materials

Metal

Markforged Metal Filaments combine the simplicity and safety of FFF printing with the superior properties of advanced metals, bringing metal 3D printing to your benchtop.

- 17-4PH Stainless Steel

- 316L Stainless Steel

- Copper

- H13 Tool Steel

- Inconel 625

- A2 Tool Steel

- D2 Tool Steel

Plastics

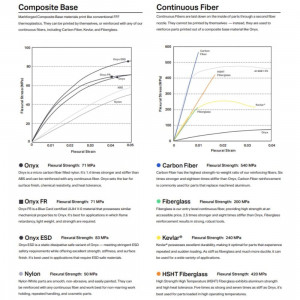

Composite Base filaments are engineering-grade materials that print using a conventional FFF (FDM-style) process. Print with them alone or with Continuous Fibers to yield strong parts. The ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries.

Continuous Fiber

Continuous Fibers enable Markforged composite printers to print metal-strength parts. They cannot be used alone — however, when printed with a Composite Base, they form the backbone of a strong printed part.