- Stock: In Stock

- Product code: 00-00012670

- Shipping Weight: 1,600.00kg

- SKU: F-FG-0007

Markforged 150cc Carbon Fiber FR-A: Flame-Retardant Carbon Fiber

Markforged Carbon Fiber FR-A 150cc is a flame-retardant composite material designed for reinforcing parts on Markforged industrial 3D printers (X7, FX10, FX20). The material provides strength comparable to aluminum, but with significantly less weight.

The material is compatible with the following Markforged 3D printers: X7, FX10, FX20.

Key Characteristics of Carbon Fiber FR-A 150cc

- Material Type: Continuous Carbon Fiber (CCF).

- Feature: Enhanced flame resistance (Flame-Retardant, FR-A).

- Continuous Fiber Fabrication (CFF) Technology

Flame Resistance (FR-A)

Advantages of Carbon Fiber FR-A

- Highest strength-to-weight ratio. Bending and tensile strength are 8 times higher than ABS plastic and comparable to the strength of aluminum. This allows designers to replace metal components with lightweight and quickly manufactured composite analogs.

- Mass optimization. Weight reduction is critically important for robotics (increasing accuracy and reducing inertia) and the transportation industry (improving fuel efficiency).

- Thermal and chemical resistance. The material is resistant to aggressive environments and demonstrates high dimensional stability at elevated temperatures, which is important for manufacturing tooling.

- Speed and cost-effectiveness. Continuous fiber 3D printing technology shortens the product development cycle and minimizes reliance on expensive traditional machining.

Application Areas of Carbon Fiber FR-A

- Carbon Fiber FR-A is ideal for creating parts that must be simultaneously strong, lightweight, and flame-resistant:

- Aerospace industry: interior elements, brackets, and tooling requiring flame resistance.

- Automotive industry: lightweight components for motorsports, tooling for assembly lines.

- Defense industry: strong and lightweight elements for UAVs and robotics.

- Industrial manufacturing: high-strength grippers, jigs, and fixtures subjected to high loads.

- Robotics: rigid and lightweight manipulator elements where low inertia is critical.

Integration into the Markforged Ecosystem

- Manufacturing Process. Requires a Markforged printer with a CFF head. Printing is two-stage: first, a polymer shell (Onyx) is created, then the CFF head lays down continuous fiber precisely along the paths specified by the engineer in the Eiger software.

- Eiger Software. The cloud-based Eiger software provides precise control over fiber placement. It allows for isotropic or anisotropic reinforcement, optimizing part strength locally and minimizing material consumption.

- Reproducibility and Reliability. Proprietary materials guarantee high reproducibility. The system automatically recognizes the spool, optimizes print parameters, and ensures reliable bonding of the fiber with the matrix.

Order Filament for Markforged 3D Printer with Delivery

When you choose to buy Carbon Fiber FR-A 150cc from us, you receive:

- Original product from the official Markforged representative in Ukraine

- Guaranteed quality, fair prices, discounts for regular customers

- Expert support both in selecting the filament and during its use

Call us, we'll save you time: we'll quickly select the plastic for your specific tasks.

3D Printers

- Metal X

- FX10

- FX20

- X7 (Gen 2)

- X7 (Gen 2) Field Edition

- X7 (Gen 2) Field Edition Brochure

- Mark Two (Gen 2)

- Onyx Pro (Gen 2)

Additional Equipment

Materials

Metal

Markforged Metal Filaments combine the simplicity and safety of FFF printing with the superior properties of advanced metals, bringing metal 3D printing to your benchtop.

- 17-4PH Stainless Steel

- 316L Stainless Steel

- Copper

- H13 Tool Steel

- Inconel 625

- A2 Tool Steel

- D2 Tool Steel

Plastics

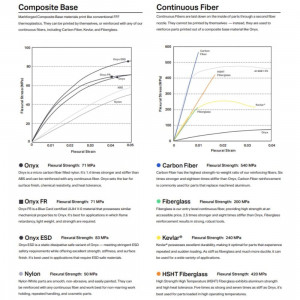

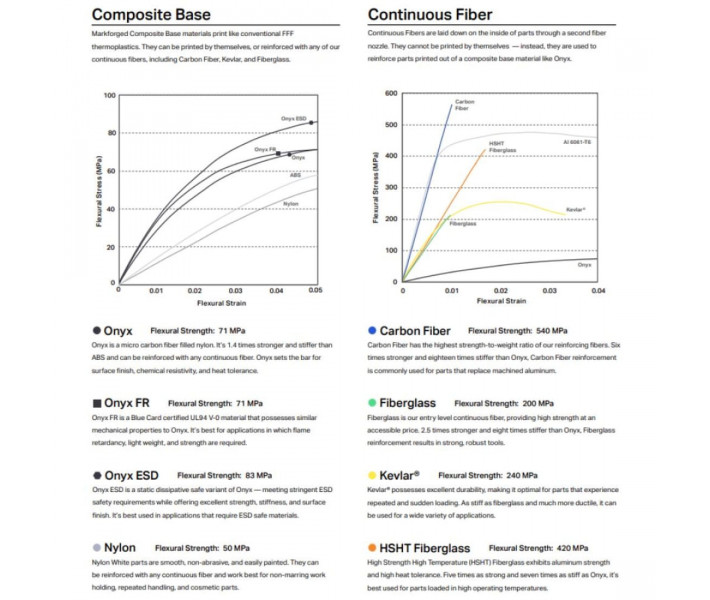

Composite Base filaments are engineering-grade materials that print using a conventional FFF (FDM-style) process. Print with them alone or with Continuous Fibers to yield strong parts. The ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries.

Continuous Fiber

Continuous Fibers enable Markforged composite printers to print metal-strength parts. They cannot be used alone — however, when printed with a Composite Base, they form the backbone of a strong printed part.