- Stock: In Stock

- Product code: 00-00013299

- Shipping Weight: 4.50kg

- SKU: 21024

Markforged D2 Tool Steel Filament – Wear-Resistant Material for Cold Processing

The Markforged D2 Tool Steel filament is a high-carbon, high-chromium steel that is air-hardened and capable of heat treatment to achieve high hardness and compressive strength. Due to its unique properties, this material is ideal for manufacturing parts that operate under abrasive wear conditions and require maximum wear resistance.

Supply format – D2 Tool Steel 400cc, compatible with the industrial Metal X™ 3D printing system. This material meets the chemical requirements of ASTM A681, ensuring stability of characteristics and compliance with international standards.

Main Advantages of the Material

The Markforged D2 Tool Steel filament is a professional solution for manufacturing parts and tools that require maximum hardness, wear resistance, and durability. It combines the advantages of traditional tool steel with the flexibility of 3D printing, opening new opportunities for industrial enterprises and manufacturing workshops.

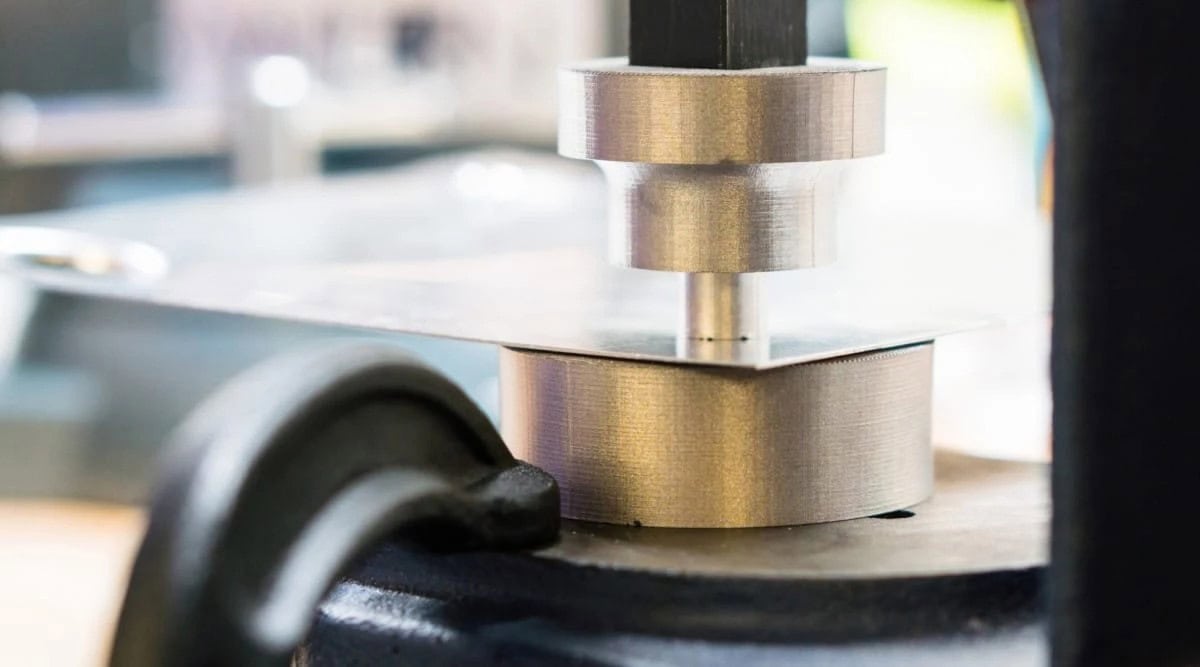

Markforged D2 Tool Steel has balanced mechanical properties that make it one of the most popular solutions for tool manufacturing.

- high hardness after heat treatment – up to 55 HRC

- excellent wear resistance even under prolonged use

- resistance to abrasive wear

- ability to maintain sharp cutting edges

- excellent compressive strength

This makes D2 filament for 3D printing an optimal choice for parts that operate under high loads.

Technical Specifications

- type of steel – cold-work tool steel D2

- hardness after heat treatment – 55 HRC

- format – spool 400 cc

- standard – ASTM A681

- compatibility – tool steel for Metal X

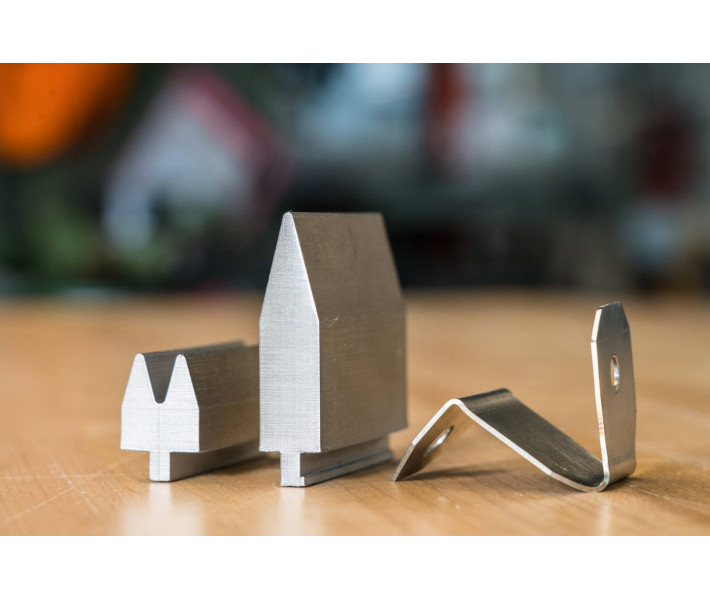

Areas of Application

The Markforged D2 Tool Steel filament is used in manufacturing where strength, compressive resistance, and durability are required. Main areas of use:

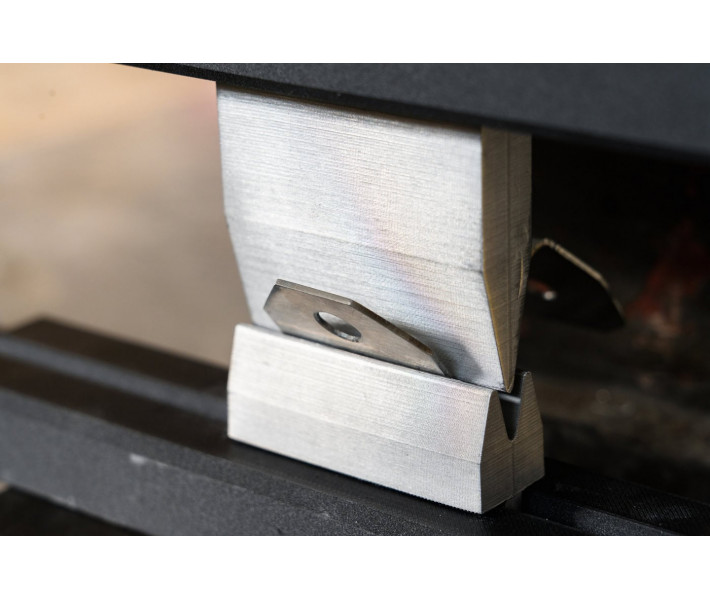

- forming tools

- dies for cold metal processing

- molds

- punch dies

- sheet metal cutting knives

- wear-resistant inserts

Why Choose D2 Tool Steel?

Compared to other tool steels, wear-resistant D2 steel stands out for its superior abrasive resistance. It is less tough than A2, but significantly surpasses it in wear resistance. Due to these properties, tool steel for dies and molds is a benchmark material in machine engineering, metalworking, and equipment manufacturing.

Heat Treatment to Enhance Properties

To unlock the material's potential, the manufacturer recommends performing heat treatment:

- heating to 1000 °C (1830 °F) in a standard furnace

- holding for 30–45 minutes

- air cooling to 65 °C (150 °F)

- subsequent tempering at 200 °C (392 °F) for 30 minutes

If necessary, double tempering is possible to achieve stable hardness and durability.

Manufacturing Advantages of 3D Printing with D2 Steel

Thanks to Metal X™ technology, you can manufacture complex geometric parts with high-precision cutting edges and functional prototypes without traditional machining costs.

Key benefits:

- reduction of production cycle

- material savings due to the additive approach

- ability to create custom tools for specific tasks

- minimization of waste while preserving steel properties

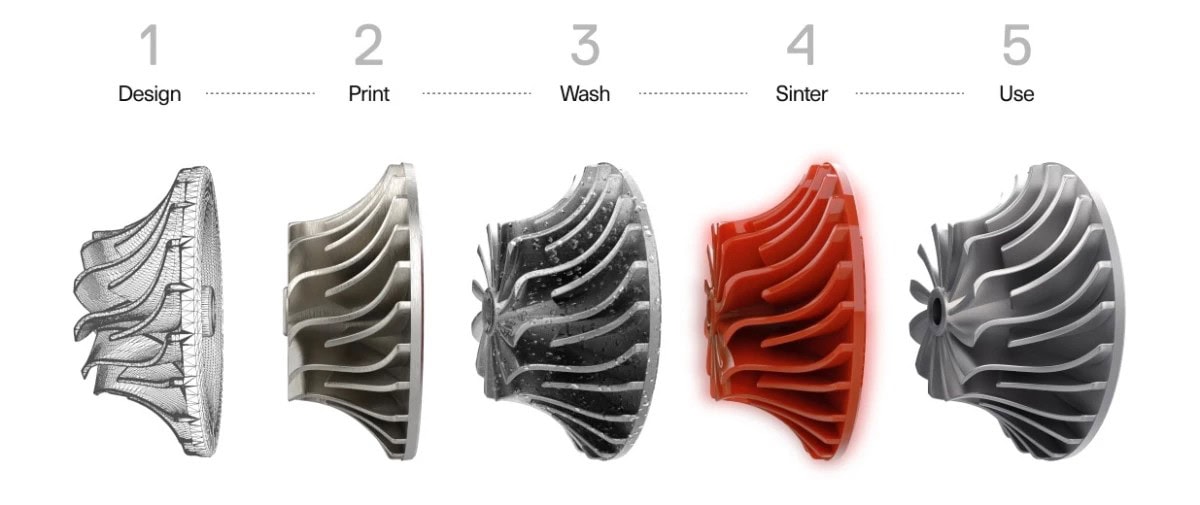

ADAM Manufacturing Technology

The process of manufacturing parts from this material is based on ADAM (Atomic Diffusion Additive Manufacturing) technology. The essence of the technology is that stainless steel powder is contained in a polymer binder, which is fed into the nozzle based on the principles of classic FDM printing. The subsequent sintering process leads to atomic diffusion, resulting in a fully metallic part with excellent mechanical properties.

Buy Markforged Tool Steel for 3D Printing in Ukraine

By ordering D2 Tool Steel in a volume of 400cc from 3DDevice as the official representative of Markforged in Ukraine, you receive a guarantee of the original product, professional consultation, and support at every stage. We have been working in the field of additive technologies since 2012 and strive to apply our experience to help you select optimal materials and solutions for your production.

3D Printers

- Metal X

- FX10

- FX20

- X7 (Gen 2)

- X7 (Gen 2) Field Edition

- X7 (Gen 2) Field Edition Brochure

- Mark Two (Gen 2)

- Onyx Pro (Gen 2)

Additional Equipment

Materials

Metal

Markforged Metal Filaments combine the simplicity and safety of FFF printing with the superior properties of advanced metals, bringing metal 3D printing to your benchtop.

- 17-4PH Stainless Steel

- 316L Stainless Steel

- Copper

- H13 Tool Steel

- Inconel 625

- A2 Tool Steel

- D2 Tool Steel

Plastics

Composite Base filaments are engineering-grade materials that print using a conventional FFF (FDM-style) process. Print with them alone or with Continuous Fibers to yield strong parts. The ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries.

Continuous Fiber

Continuous Fibers enable Markforged composite printers to print metal-strength parts. They cannot be used alone — however, when printed with a Composite Base, they form the backbone of a strong printed part.