- Stock: In Stock

- Product code: 00-00013284

- Shipping Weight: 4.50kg

- SKU: MF-F-MF-20876

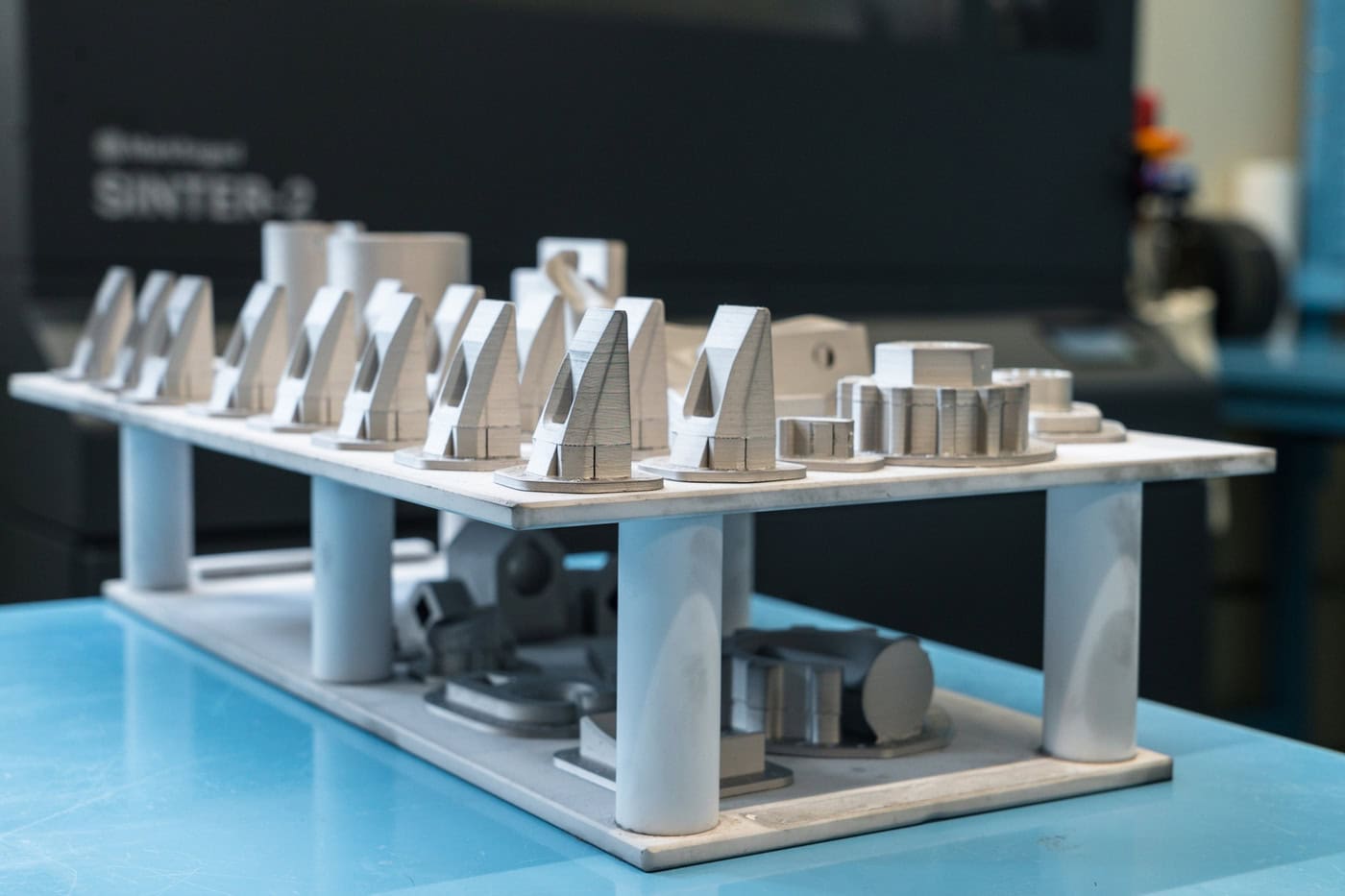

The Markforged 17-4PH Stainless Steel V2 400cc filament is a high-quality material for industrial metal 3D printing that combines strength, corrosion resistance, and heat treatability.

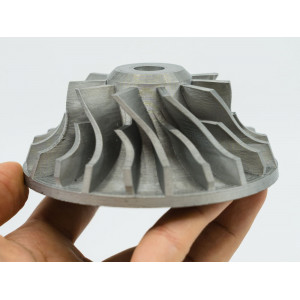

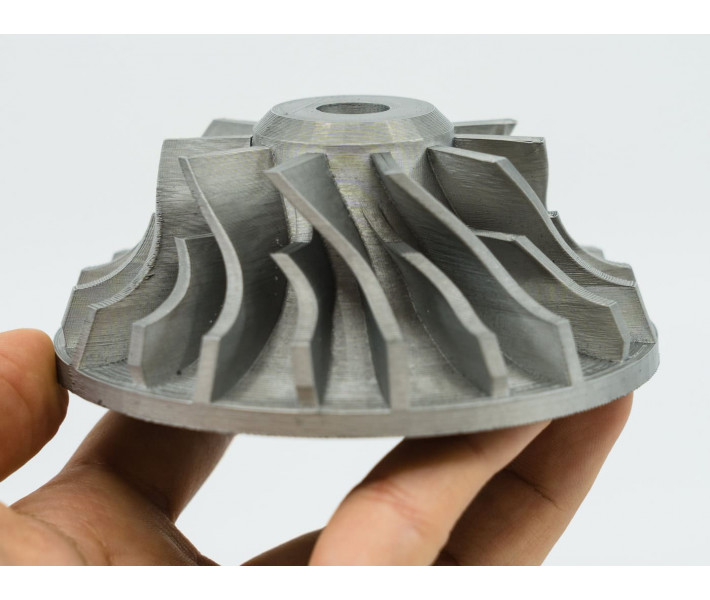

Obtain fully metal parts for engineering tasks with properties close to forged steel. The material is ideal for creating tools, functional prototypes, and complex geometries that are virtually impossible to manufacture using traditional methods.

With the 17-4PH Stainless Steel V2 400cc, users can achieve engineering tasks with maximum precision and reliability.

Main Features of Markforged 17-4PH Stainless Steel Filament

17-4PH stainless steel V2 is an updated version of the material with an improved binder composition that provides even better workability.

- heat treatable up to a hardness of 36 HRC;

- strength reaches 95% of forged steel properties;

- versatility in industrial applications – from tooling to low-volume production;

- high wear resistance and corrosion resistance.

Compatibility

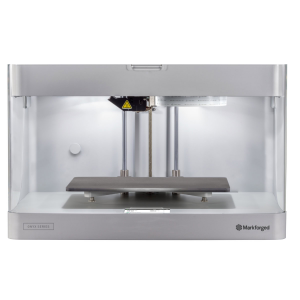

The metal filament is fully compatible with Markforged Metal X and FX10 3D printers, which have the Markforged FX10 Metal Kit.

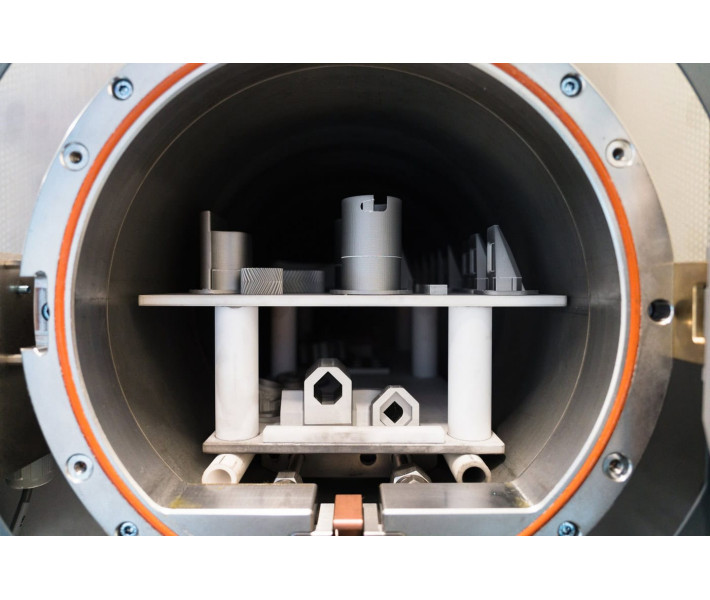

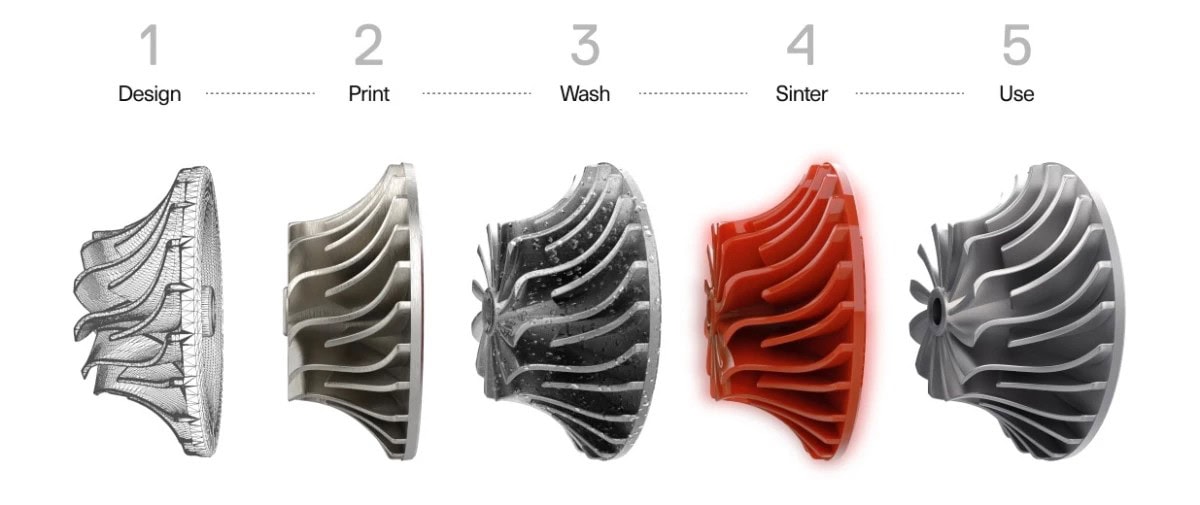

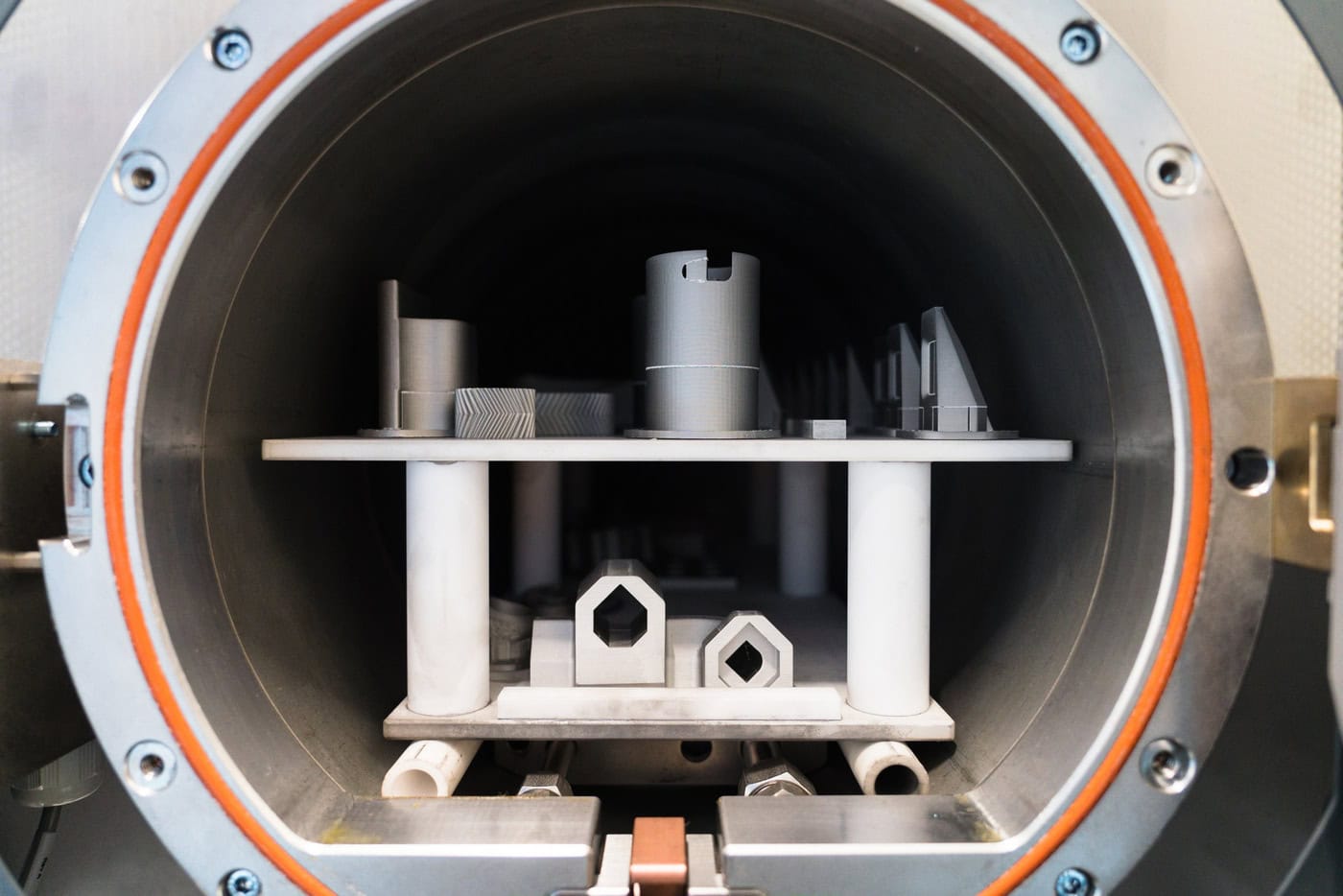

ADAM Manufacturing Technology

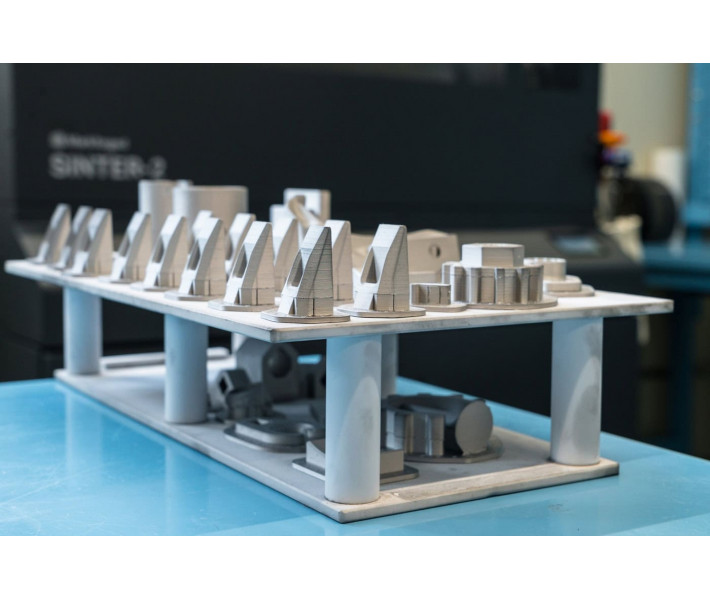

The process of manufacturing parts from this material is based on ADAM (Atomic Diffusion Additive Manufacturing) additive manufacturing. The essence of the technology is that stainless steel powder is contained in a polymer binder, which is fed into the nozzle based on the principles of classic FDM printing. The subsequent sintering process leads to atomic diffusion, resulting in a fully metal part with excellent mechanical properties.

Applications

By using stainless steel for 3D printing, engineers and manufacturing companies gain extensive capabilities:

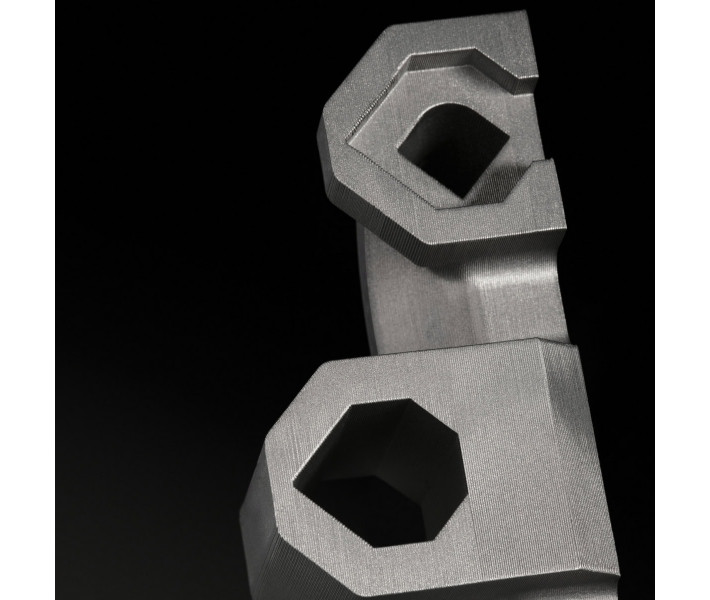

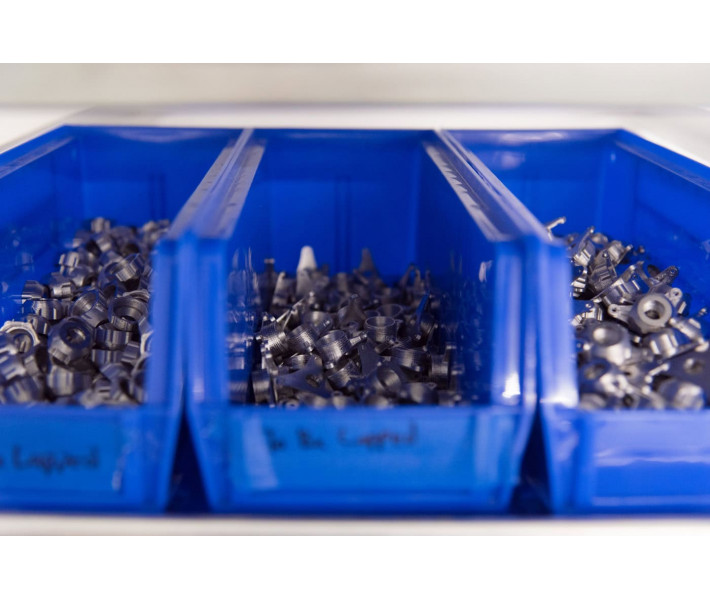

- creation of end tools and fixtures;

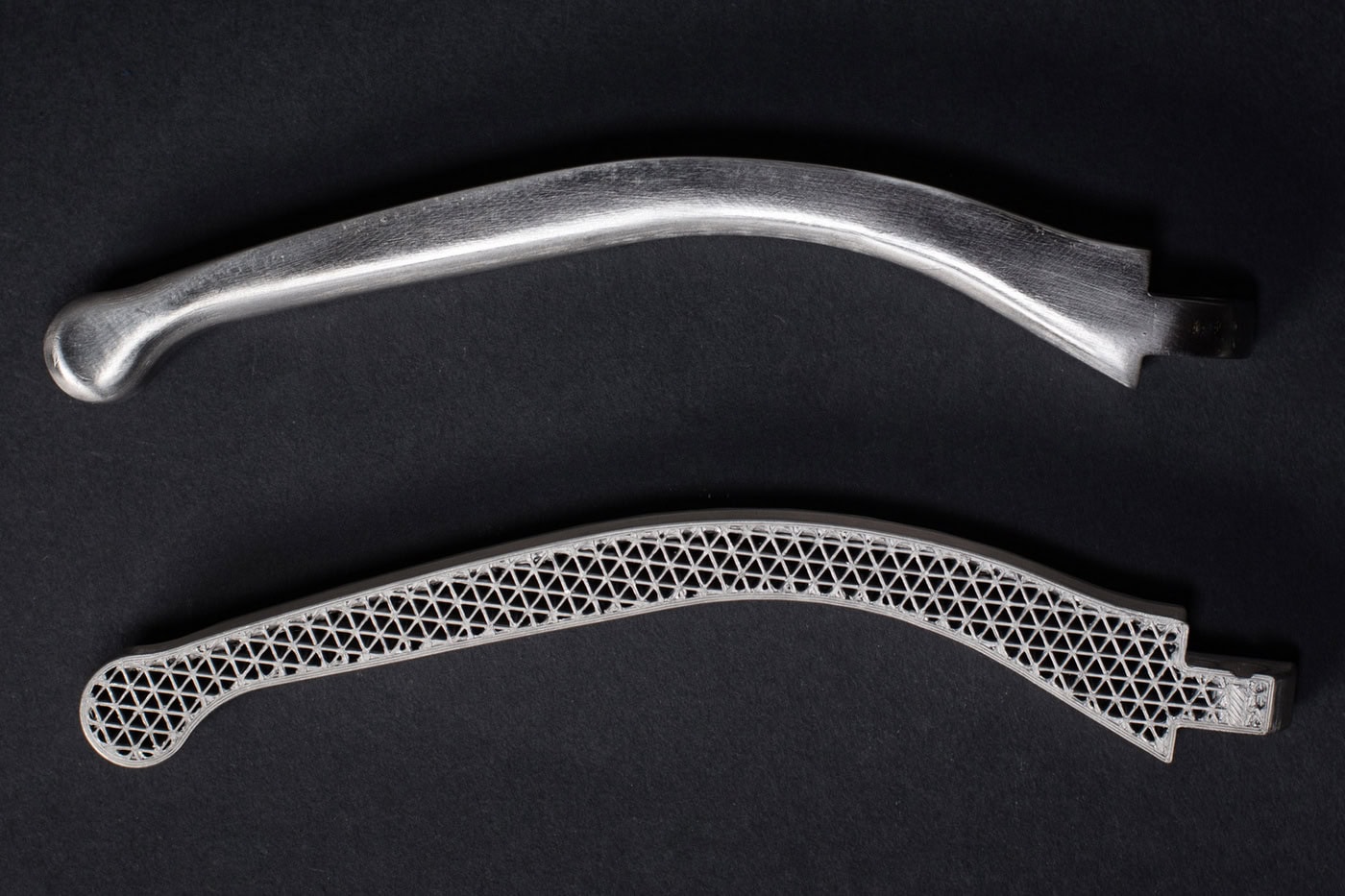

- lightweight yet strong brackets and structural elements;

- high-wear-resistant tools for industrial use;

- functional prototypes and experimental samples;

- specialized wrenches and attachments;

- low-volume production of parts;

- manufacturing of spare parts and components with complex geometry.

Mechanical Properties of 17-4PH Stainless Steel

A material for creating precise and durable components that meet industrial sector standards:

- Tensile Strength – 1050 MPa (in the state after sintering), 1250 MPa (after heat treatment).

- Hardness – 30 HRC (in the state after sintering), 36 HRC (after heat treatment).

Advantages in Manufacturing

- Significantly reduces the time required to manufacture tooling, prototypes, and tools: a few days instead of several weeks.

- Manufactures complex-shaped elements that cannot be realized using standard machining or even DMLS.

When to Choose 17-4PH

The filament performs best in production environments where hard, rigid, and corrosion-resistant parts are required. It is suitable for low-volume production, creating spare parts, engineering tools, and components that must withstand high loads.

When heat treated under H900 conditions (heating to 482 °C for 4 hours), parts achieve maximum strength and hardness. To enhance impact toughness, the H1150 mode can be used, making the material more ductile by reducing ultimate strength.

For more details on the production process for metal parts made from Markforged 17-4PH steel, please watch the video:

Buy Markforged Metal Filament in Ukraine

Choose Markforged 17-4PH Stainless Steel Filament from us – the official representative of Markforged in Ukraine.

As specialists with over 10 years of experience in 3D printing, we provide expert consultations and assistance in selecting solutions tailored to your tasks and budget. By purchasing from us, you receive an original product and complete confidence in its quality.

3D Printers

- Metal X

- FX10

- FX20

- X7 (Gen 2)

- X7 (Gen 2) Field Edition

- X7 (Gen 2) Field Edition Brochure

- Mark Two (Gen 2)

- Onyx Pro (Gen 2)

Additional Equipment

Materials

Metal

Markforged Metal Filaments combine the simplicity and safety of FFF printing with the superior properties of advanced metals, bringing metal 3D printing to your benchtop.

- 17-4PH Stainless Steel

- 316L Stainless Steel

- Copper

- H13 Tool Steel

- Inconel 625

- A2 Tool Steel

- D2 Tool Steel

Plastics

Composite Base filaments are engineering-grade materials that print using a conventional FFF (FDM-style) process. Print with them alone or with Continuous Fibers to yield strong parts. The ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries.

Continuous Fiber

Continuous Fibers enable Markforged composite printers to print metal-strength parts. They cannot be used alone — however, when printed with a Composite Base, they form the backbone of a strong printed part.