Out of stock

3D printer Flashforge Creator 4-A

- Stock: Out of stock

- Product code: 00-00011600

Based on 0 reviews.

-

Write a comment

₴441 045.00

Ex Tax: ₴441 045.00

Quantity:

Flashforge Creator 4-A — 3D Printing for Any Task

Flashforge Creator 4 is a versatile, adaptive, and productive 3D printer, designed for professional use in manufacturing.

Thanks to three interchangeable extruder modules, it can print with a wide range of materials, satisfying a variety of needs:

- Flexible filaments – for creating flexible and elastic models.

- Engineering filaments – for printing strong and durable parts.

- Carbon fiber composite filaments – for manufacturing lightweight and strong products.

On this page, the Creator 4-A includes an additional HT extruder, extending the printing range up to 320 °C.

Key Features

- Three modular extruders – print with a wide range of materials, including flexible filaments, engineering filaments, and composite filaments.

- Two independent IDEX extruders – double your productivity or print complex multi-material models.

- Large print volume 400*350*500 mm – create large objects with high precision.

- High-temperature printing up to 320 °C – enables the use of various types of high-temperature engineering filaments.

- Chamber heating up to 65 °C and platform heating up to 120 °C – reduce warping and improve adhesion.

- Wide filament compatibility – use different materials from Flashforge and other manufacturers.

- Smart filament management system.

- Built-in filament compartment 2 kg + 1 kg.

- 7-inch smart touchscreen.

- Intelligent features and safety – resume printing after power loss, remote monitoring with a camera, automatic shutdown, HEPA 13 air filters.

Industrial 3D Printer Flashforge Creator 4-A

- Versatile – prints from a wide range of materials.

- Flexible – modular extruder system.

- Productive – high printing speed up to 200 mm/s and accuracy.

- Reliable – durable steel construction and high-quality components.

- Easy to use — intuitive software.

More about the Creator 4-A's capabilities

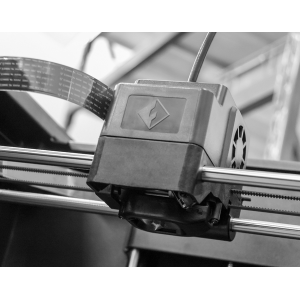

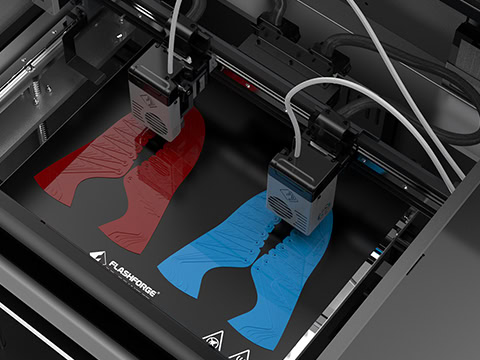

1. Two independent IDEX extruders

- Print simultaneously with two extruders to double your productivity.

- Create multi-material models with different textures and properties.

- Extruders print independently of each other.

2. Three modular extruders for different filaments

- Extruder-F – for printing with flexible filaments.

- Extruder-HT – for printing with engineering filaments.

- Extruder-HS – for printing with carbon fiber composite, glass-filled, etc., filaments.

|

|

|

|

| Extruder Type | Extruder-F | Extruder-HT | Extruder-HS |

| Purpose | Printing with 85A flexible filament | Printing with engineering filaments | Printing with carbon fiber composites |

| Print Speed | 100 mm/s | 200 mm/s | 150 mm/s |

| Filament Diameter | 2.85 mm | 1.75 mm | 1.75 mm |

| Print Temperature | 265 °C | 320 °C | 360 °C |

| Supported Materials | TPU 85A, TPE, TPB, TPC | PC, PA, PP, PETG, ASA, ABS, PLA, PC-ABS, PAHT, PVA | PACF, PET-CF, PP-CF, PA-GF, PC-ABS, PP-GF, PPS-CF, PPS |

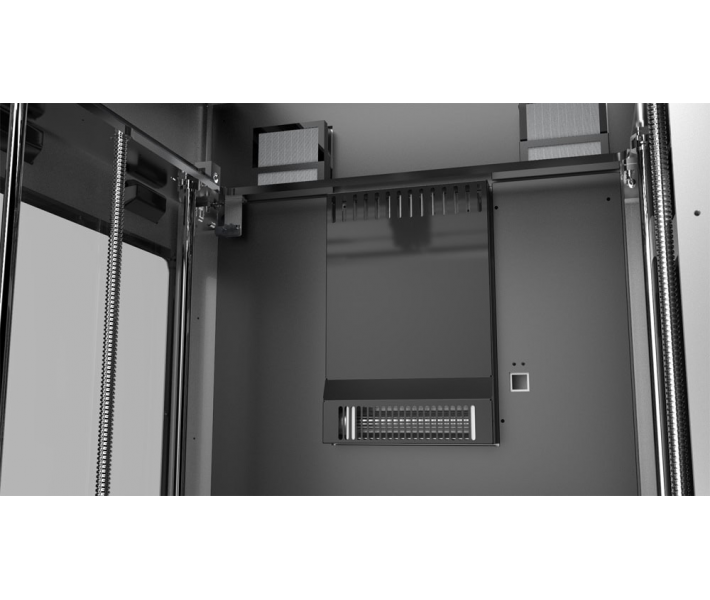

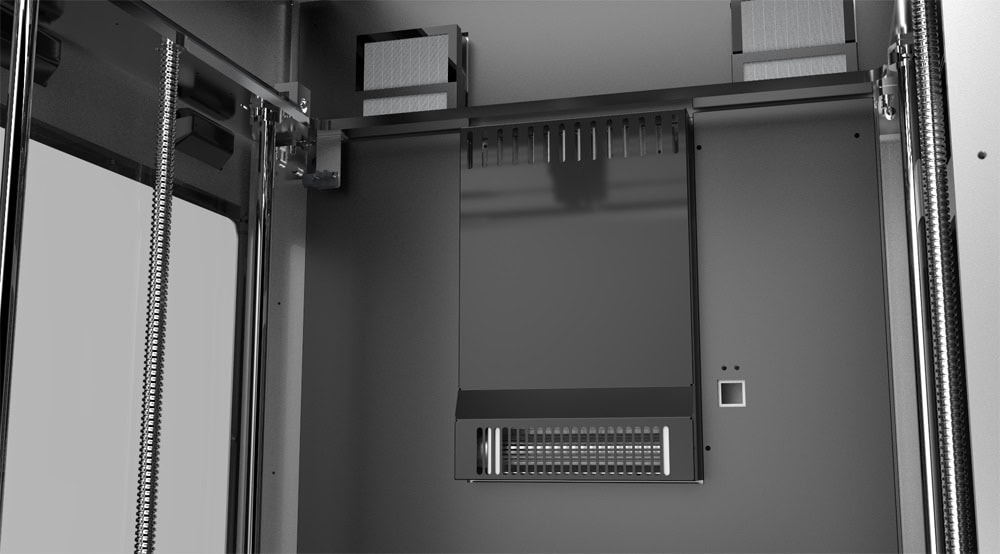

3. Print Chamber heating up to 65 °C and Build Platform heating up to 120 °C

- Reduces warping and cracking of models.

- Improves adhesion to the print platform.

- Maintains a stable temperature throughout the entire printing process.

4. Large print volume, enclosed build chamber

- 400*350*500 mm – enough space for creating large objects.

- Suitable for printing complex parts and mockups.

5. High-precision 3D printing

- Linear rails and lead screws ensure smooth and precise movement.

- S-type motion control system guarantees high print quality. It ensures smoother starting and stopping, precise nozzle positioning, and excellent print details.

6. User-friendly and intelligent filament management system

- Automatic temperature setting for various filaments.

- Manual temperature setting capability.

- Convenient design for subsequent printing.

7. Wide compatibility with 3D plastics

- Supports Flashforge Supreme filaments with high print quality.

- Compatible with third-party filaments.

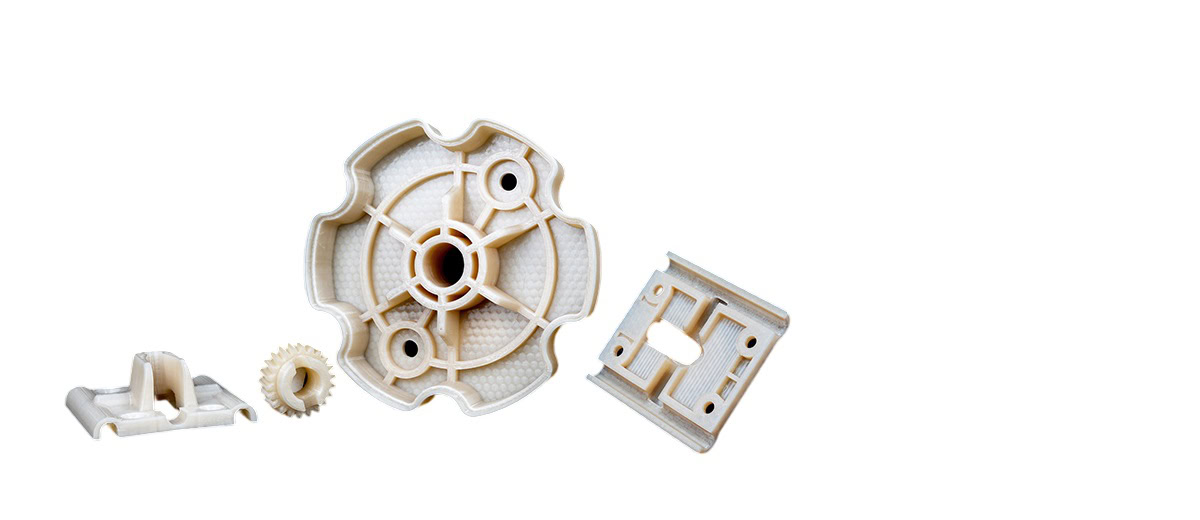

8. Application Cases

- Functional prototyping — quickly bring your ideas to life.

- Customized parts manufacturing — print strong and durable parts, tools, fixtures, spare parts, etc.

- Small and medium-batch production.

- Education — teach students 3D printing and engineering.

- Design — create complex and innovative models.

- Medicine — print anatomical models and surgical guides.

Specification

| Printing Technology | FDM/FFF |

| Build Volume (mm) | 400*350*500 |

| Filament Diameter (mm) | 1.75 |

| Maximum Nozzle Temperature (°C) | 320 |

| Number of Extruders | 2 |

| Build Chamber Type | Enclosed |

| Filament Chamber Type | Enclosed |

| Chamber Heating | Yes |

| Filament Drying | Available |

| Feeding Mechanism Type | Direct |

| Extruder Structure Type | IDEX — Independent Dual Extruders |

| Nozzle Diameter (mm) | 0.4, (0.6/0.8) |

| Printing Speed (mm/s) | 200 |

| Maximum Chamber Temperature (°C) | 65 |

| Platform Heating | Available |

| Maximum Platform Temperature (°C) | 120 |

| Platform Material | Flexible Steel Platform |

| Open Filament System | Yes |

| Supported Materials | PLA, PETG, PC-ABS, PAHT, PVA, ABS,ASA, PP, PA, PC |

| Air Filter | HEPA 13 |

| Control | 7″ touchscreen |

| Body Material | Stainless Steel |

| Presence of Camera | Yes |

| Features | Built-in camera, real-time remote monitoring, power loss recovery, sealed drying chamber, automatic shutdown |

| Supported File Types | 3MF, STL, OBJ, FPP, BMP, PNG, JPG, JPEG, GX, G File, GCODE |

| Power Requirements | AC 100–240 V, 50/60 Hz, 30 А |

| Output Power | 2300W |

| Country of Origin | China |

| Warranty Period (months) | 12 |

| Net Weight (kg) | 90.0 |

| Net Dimensions (mm) | 840×675×1050 |

| Gross Weight (kg) | 95.0 |

| Gross Dimensions (mm) | 990×820×1260 |

| Operating Environment Temperature Range (°C) | 15 — 30 |