- Stock: Price on request

- Product code: 00-00012252

- Shipping Weight: 54.00kg

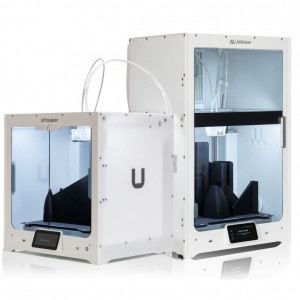

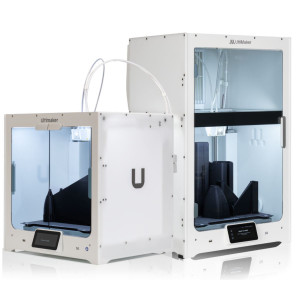

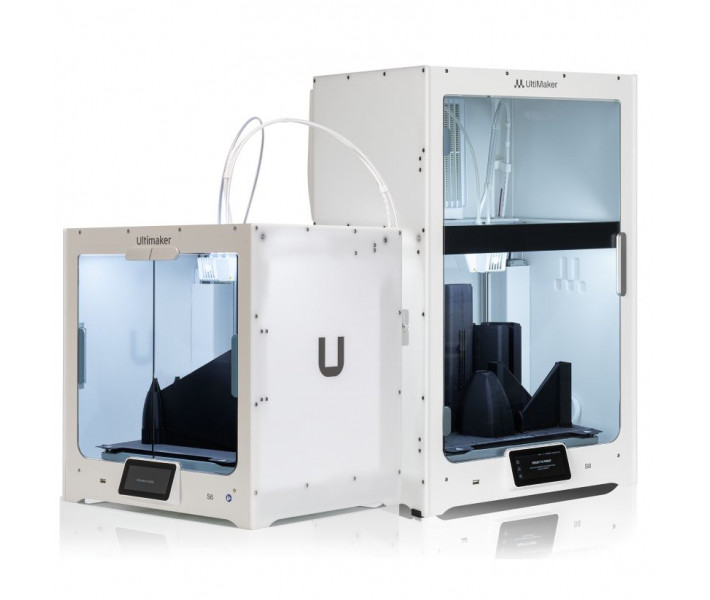

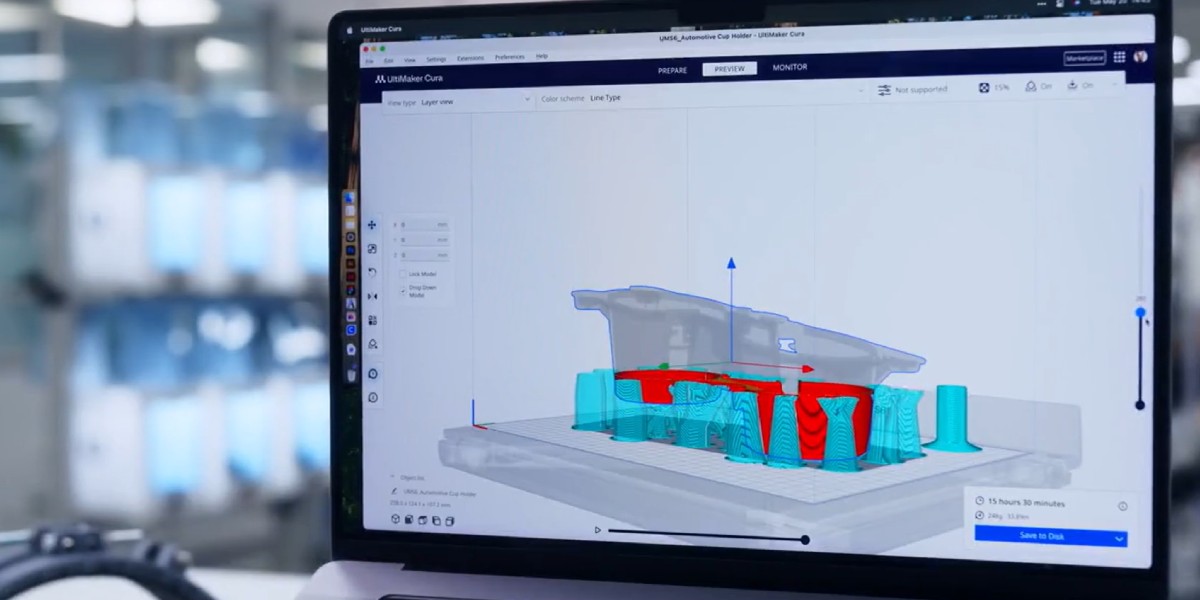

Professional Ecosystem UltiMaker S6 Pro Bundle: Automation Out of the Box

The UltiMaker S6 Pro Bundle Flex Plate is not just a 3D printing device, but a fully automated production station designed for 24/7 operation. This bundle is developed for engineers, designers, and production sites where reliability and minimal operator involvement in the maintenance process are critically important.

Literally, "Pro Bundle" means you get a complete system that independently manages material humidity, filters air, and ensures easy removal of finished parts thanks to an innovative flexible platform.

Bundle Composition and Functionality of Each Module

To understand the value of this solution, it is necessary to break down each element included in the Pro Bundle:

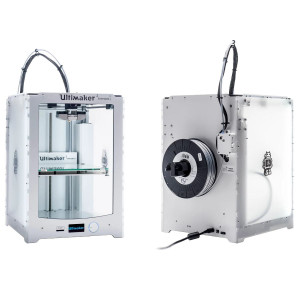

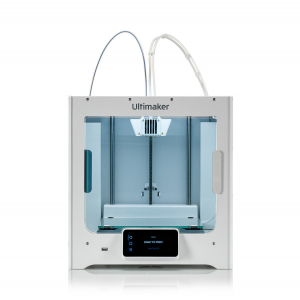

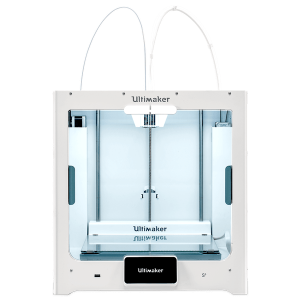

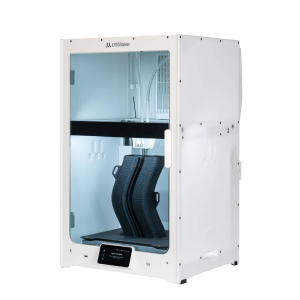

UltiMaker S-series 3D Printer

This is the "heart" of the system. The printer is equipped with a reliable dual extrusion system that allows for printing complex geometric shapes using soluble supports (PVA).

- Material Flow Sensor: automatically pauses printing if the filament runs out or gets tangled.

- Print Core System: quick-swap print heads allow you to switch from printing with standard plastics to working with abrasive composites in a matter of seconds.

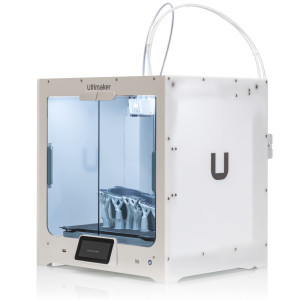

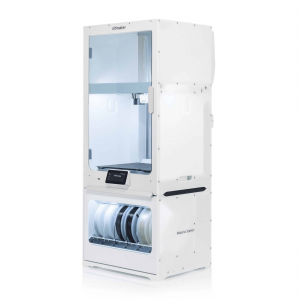

Material Station

The bottom module of the system that turns the printer into an autonomous factory.

- Automatic Loading: holds up to 6 filament spools. If one spool runs out of plastic, the station instantly switches the feed to the next one without interrupting the print.

- Microclimate Control: humidity inside the module is maintained below 20%, which is vital for hygroscopic materials (Nylon and PVA).

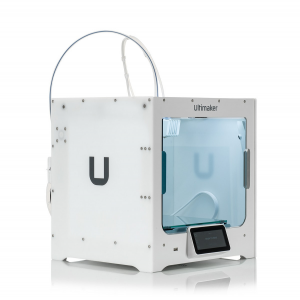

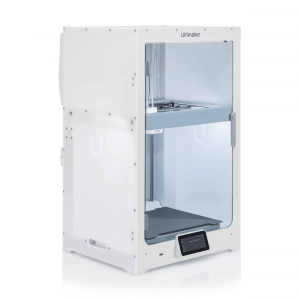

Air Manager

The top module, creating an enclosed and safe printing environment.

- UFP Filtration: the built-in EPA filter traps up to 95% of ultrafine particles.

- Thermal Regulation: the module optimizes airflows inside the chamber, preventing shrinkage of parts made from technical plastics (ABS, PC).

Flex Plate

A special addition in this configuration, replacing traditional glass.

- Easy Removal: a steel sheet with PEI coating. After work is complete, simply bend the sheet and the part will detach.

- Adhesion Without Glue: the surface provides excellent first-layer grip without additional adhesives.

Technical Specifications of UltiMaker S6 Pro Bundle

| Parameter | Value |

|---|---|

| Build Volume (XYZ) | 330 × 240 × 300 mm |

| Extrusion System | Dual, with automatic nozzle lifting |

| Filament Diameter | 2.85 mm |

| Nozzle Temperature Range | 180–280 °C |

| Build Surface | Flexible steel plate with magnetic attachment |

| Material Module | 6 slots with NFC recognition and humidity control |

| Filtration | EPA filter (up to 95% efficiency) |

| Interfaces | Wi-Fi, LAN, USB, cloud management (Digital Factory) |

Features and Innovations

The main feature of the UltiMaker S6 Pro Bundle lies in its intelligent management. Thanks to built-in NFC readers, the Material Station itself informs the printer which type and color of plastic is loaded. Inductive bed calibration sensors scan the surface before starting work, guaranteeing a perfect first layer.

Applications

- Industrial Prototyping: functional units with high precision.

- Small-Batch Production: printing end-use products without the cost of injection molds.

- Tooling Production: templates, jigs, and fixtures.

- Medicine and Education: detailed anatomical models.

The UltiMaker S6 Pro Bundle Flex Plate is a complete professional system that saves time, reduces operator involvement, and increases the predictability of results. If you plan regular printing and want maximum comfort, the Pro Bundle will be the most promising choice for your business. Visit our showroom or call us: our managers will answer any questions!