- Stock: Price on request

- Product code: 00-00012246

- Shipping Weight: 30.40kg

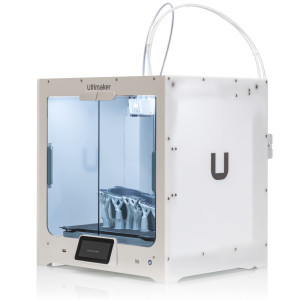

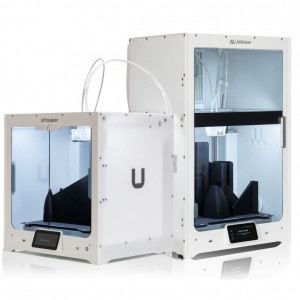

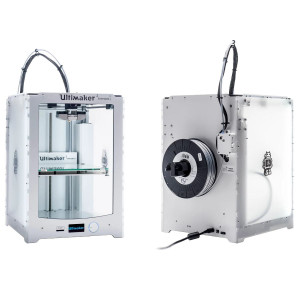

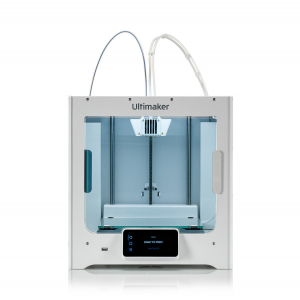

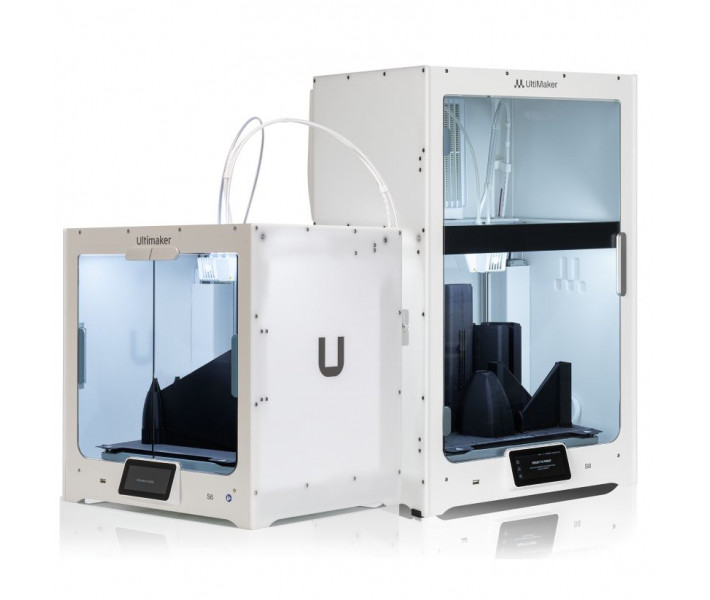

UltiMaker S6 Glass Plate: Glass Plate for Reliability and Precision

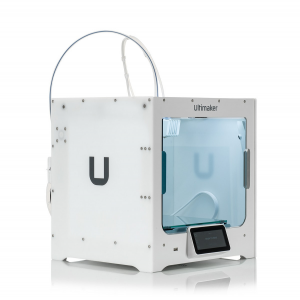

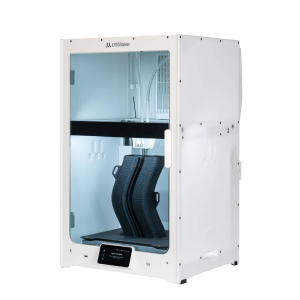

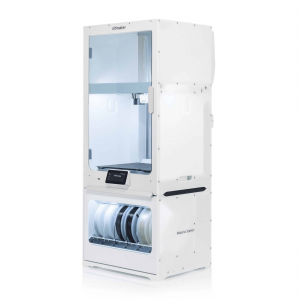

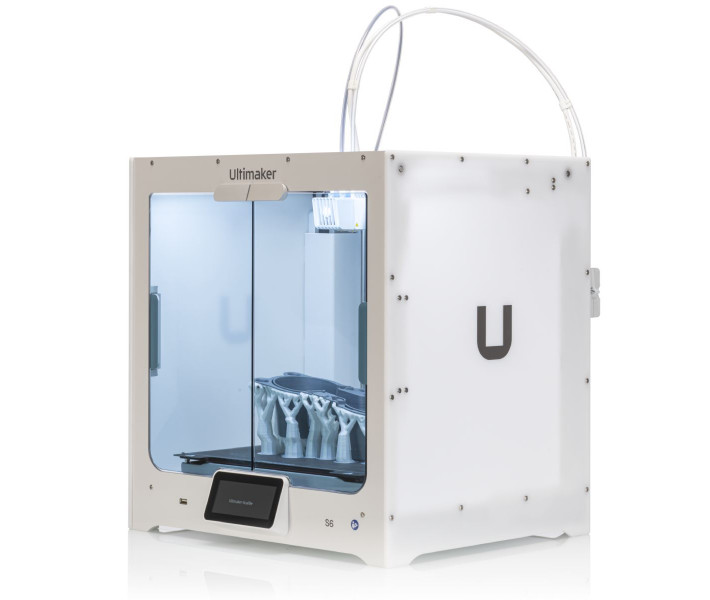

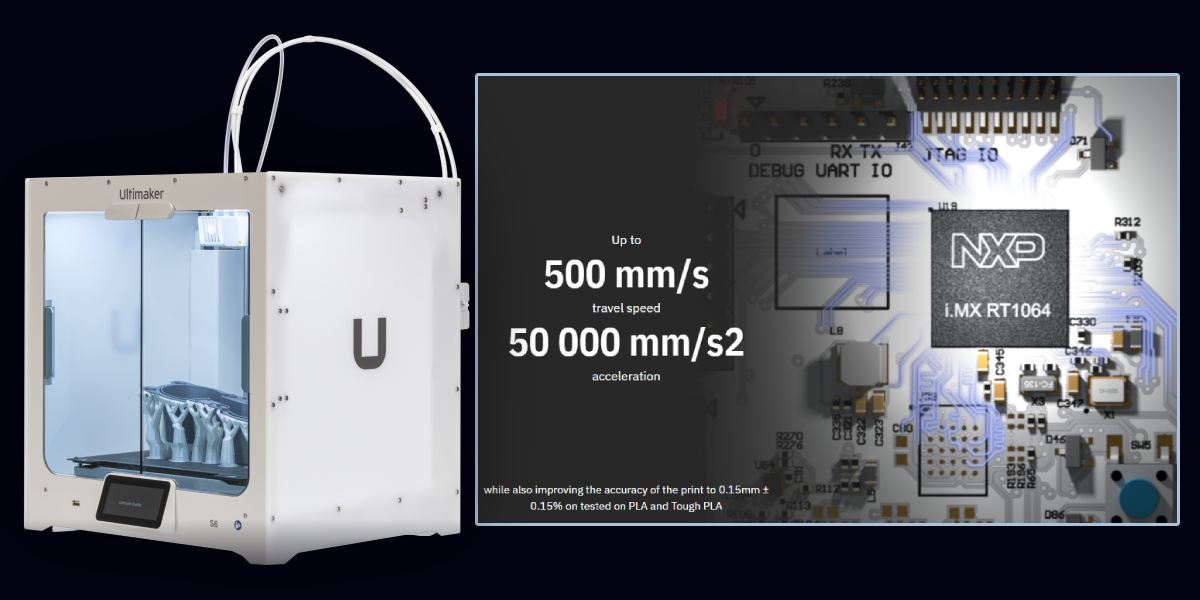

UltiMaker S6 is an evolution of the legendary S5 series, providing up to 4 times more performance thanks to the Cheetah motion planner and a new material feeding system. The quality of a finished 3D object directly depends on the stability of the first layer. The UltiMaker S6 Glass Plate is an original component designed specifically to ensure perfect adhesion and flawless model geometry. Using original glass from the manufacturer guarantees full compatibility with the printer's kinematics and automatic calibration systems.

Technical Features and Design

The glass plate for UltiMaker S6 is made of high-strength borosilicate glass. This material has an extremely low coefficient of thermal expansion: when heated to operating temperatures (up to 110°C and higher), the platform maintains perfect flatness without deforming or creating height differences.

The thickness and edge processing of the plate are optimized for quick installation into the bed clips. The glass surface undergoes thorough polishing, ensuring mirror smoothness of the bottom surface of printed parts. This is critical for functional prototypes where a tight fit between components is required.

Advantages of Using Original UltiMaker Glass

- Sterile environment: suitable for food industry and medical tasks.

- High thermal conductivity: uniform heat distribution eliminates "cold zones" and corner warping.

- Ideal adhesion: the surface is adapted for a wide range of professional filaments.

- Easy model removal: after cooling, the model "pops off" on its own.

- Durability: resistance to aggressive chemicals and scratches.

Operational Benefits

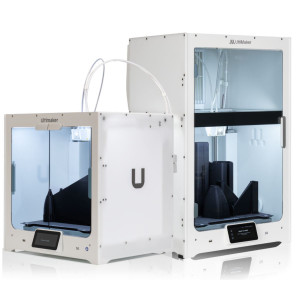

Working with a removable glass bed simplifies production: while one part is cooling, you can install a second plate and immediately start printing. The transparency of the glass allows for visual monitoring of the heater status, and the smooth surface is easy to clean with warm water or alcohol solutions.

Applications

- Industrial design: perfectly flat covers and housing bases.

- Architectural modeling: printing elements with a large footprint area.

- Engineering parts: working with high-shrinkage materials (ABS, CPE, Nylon).

UltiMaker S6 Technical Specifications

| Section | Parameter | Value |

|---|---|---|

| Technology | Print method | FDM (Fused Deposition Modeling) |

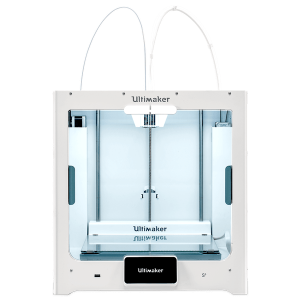

| Printing | Head | Dual with auto-lift and inductive probing |

| Mechanics | Planner | UltiMaker Cheetah (3rd order smooth motion) |

| Temperature | Nozzle / Bed | up to 340 °C / up to 120 °C |

| Accuracy | Dimensions | ±0.15 mm or ±0.15 % |

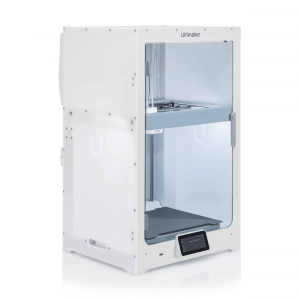

| Build volume | XYZ | 330 × 240 × 300 mm |

| Electronics | Processor | ARM Cortex Quad-core 1.8 GHz |

| Connectivity | Network | Wi-Fi (Dual Band), LAN, USB 2.0 |

| Physical | Weight | 25 kg |

Important! Switching between glass and flexible plates on a single device is not supported: these are different types of assembly blocks (requiring different calibration and mountings).

UltiMaker S6 Glass Plate is compatible with more than 300 types of plastic

Why Choose This Specific Solution

UltiMaker S6 Glass Plate is an investment in production stability. The original glass has a strictly verified thickness, which is critical for the Active Leveling sensor. This guarantees protection of the surface from damage during calibration and a perfect first layer across the entire print area. We have a wide selection of 3D printers and accessories from the world's best manufacturers. Our dedicated managers will answer all your questions – call us now!