- Stock: Price on request

- Product code: 00-00012247

- Shipping Weight: 30.40kg

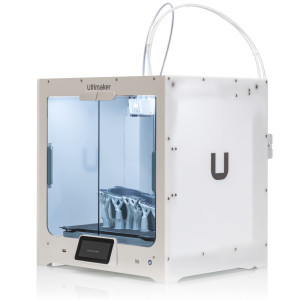

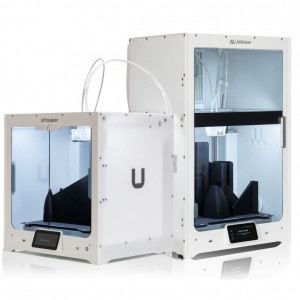

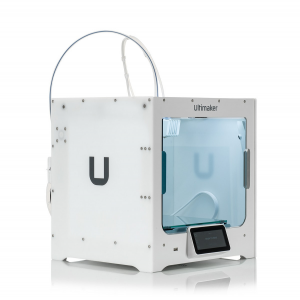

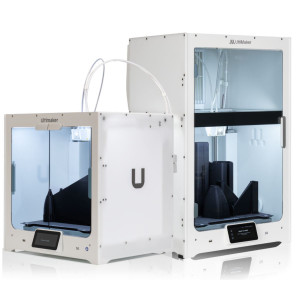

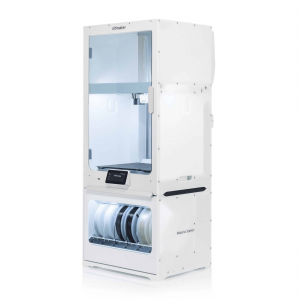

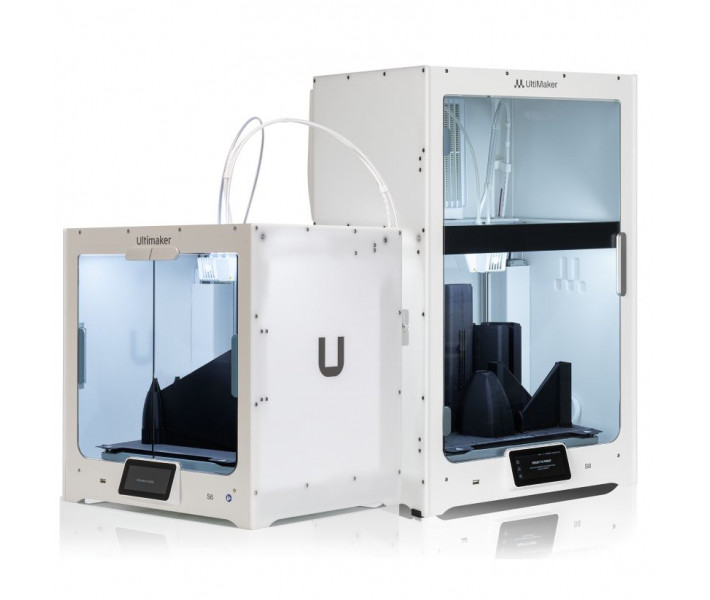

UltiMaker S6 3D Printer with Flexible Plate: Optimize Your Workflows

The UltiMaker S6 3D printer is a high-tech solution for professionals who value precision, reliability, and workflow efficiency. This model is an evolutionary continuation of the S-series, combining proven technologies with an innovative flexible spring steel platform. The device is designed for complex engineering tasks, rapid prototyping, and creating functional industrial-quality parts.

The printer is ideally suited for office and laboratory environments. It ensures high repeatability of results and maximum safety thanks to the integrated filtration system. By choosing the UltiMaker S6, you receive a complete ecosystem: software, a wide selection of materials, and cloud-based production management services.

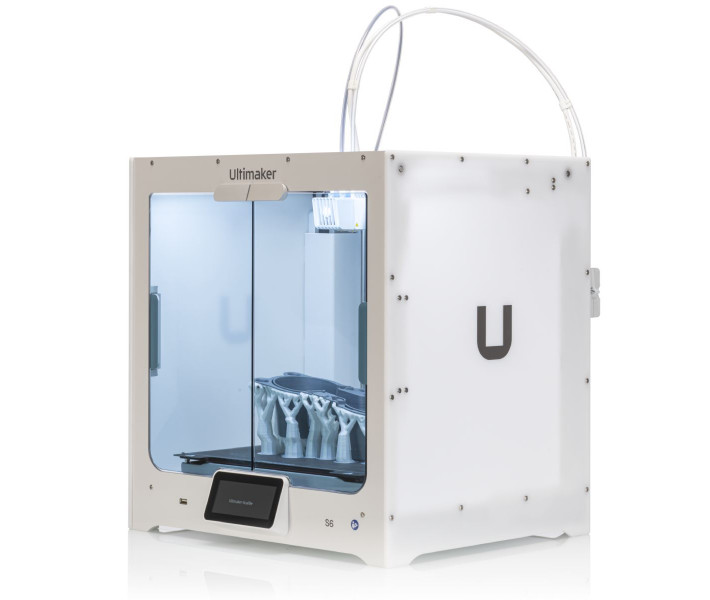

Flexible Platform for Easy Model Removal

A key feature of the UltiMaker S6 is the innovative flexible spring steel plate with a PEI coating. This solution radically simplifies the workflow:

- Ease of use: forget about spatulas. The plate is removed from the magnetic base, and the part is detached by simply bending the sheet.

- Magnetic fixation: 25 powerful magnets eliminate platform shifting during printing.

- Durability: the PEI coating is wear-resistant and guarantees perfect first-layer adhesion.

- Time-saving: rapid product removal reduces equipment downtime, which is crucial for batch production.

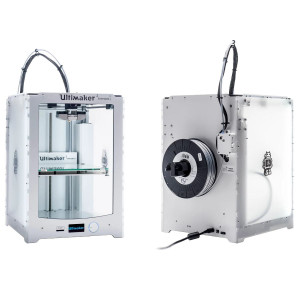

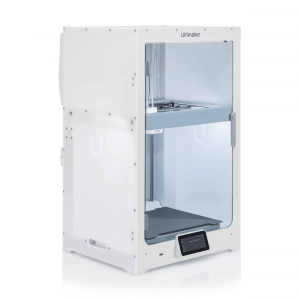

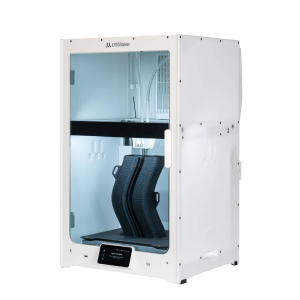

Integrated Air Manager and Enclosed Chamber

The UltiMaker S6 is equipped with a fully enclosed chamber and an air purification system. This allows for maintaining a stable temperature regime, which is critical for printing with engineering plastics (ABS, Nylon, PC).

The built-in HEPA filter and carbon filter capture up to 95% of ultrafine particles (UFP) and neutralize odors. This makes the printer's operation safe in classrooms and rooms without specialized ventilation. The stable climate inside the chamber prevents model delamination and corner warping.

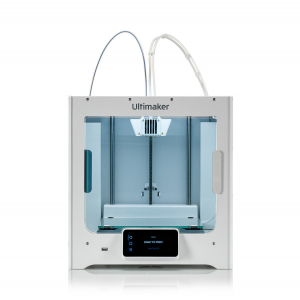

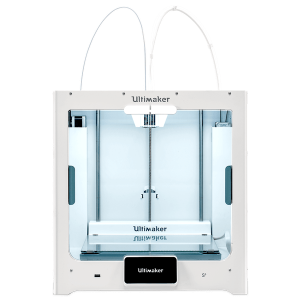

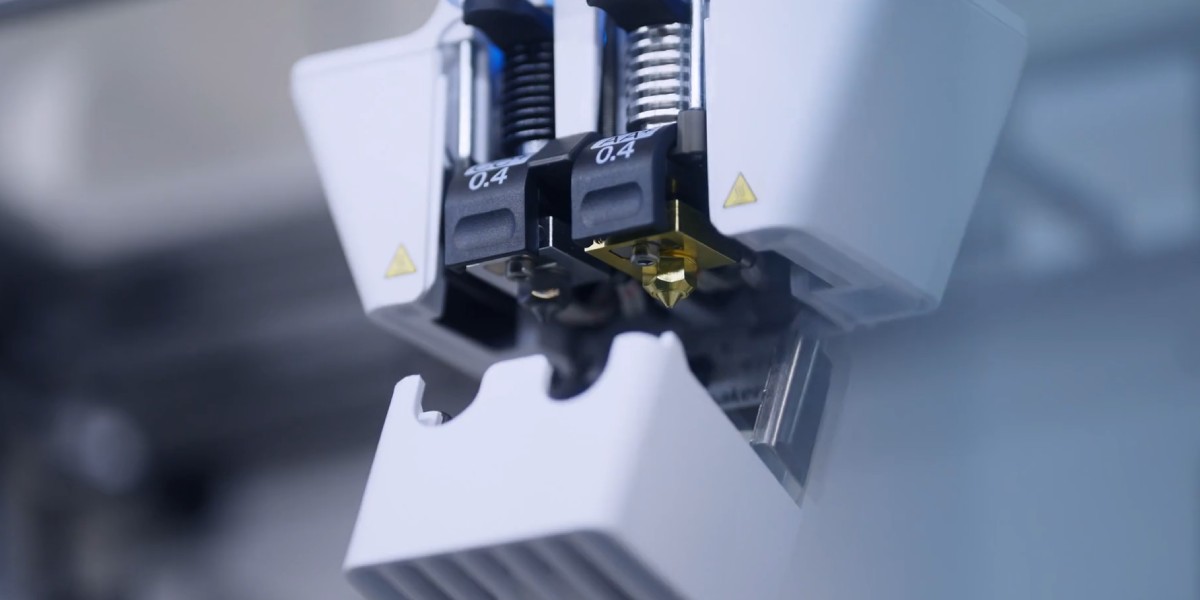

Dual Extrusion System and Print Precision

The printer utilizes a proprietary dual extrusion system with automatic nozzle lifting. This enables the printing of products with complex geometries using soluble supports (PVA).

- High precision: a tolerance of just ±0.15 mm meets mechanical engineering standards.

- Swappable print cores: Print Core technology allows for changing nozzles in seconds — from 20-micron layers to high-speed printing.

- Filament sensor: the system will automatically pause operation when the material runs out, protecting against defects.

Business Advantages

- Maximum automation: active leveling of the bed at multiple points guarantees a perfect first layer.

- Support for over 300 materials: use original plastics or filaments from world leaders (BASF, Arkema).

- 24/7 reliability: the construction is designed for continuous industrial operation.

- Cloud management: the Digital Factory service allows for remote monitoring of printing via the built-in HD camera.

Applications

- Industrial design: functional prototypes and tooling.

- Medicine: anatomical models and customized orthopedic products.

- Education: training students on world-standard equipment.

- Automotive industry: small-batch interior parts and models for testing.

Technical Specifications

| Parameter | Value |

|---|---|

| Printing Technology | FDM (Fused Deposition Modeling) |

| Build Area | 330 × 240 × 300 mm |

| Extruders | 2 (Dual Extrusion System) |

| Platform | Flexible steel with PEI coating |

| Filament Diameter | 2.85 mm |

| Positioning Accuracy | 6.9 / 6.9 / 2.5 microns |

| Filtration System | HEPA and Activated Carbon |

| Interfaces | Wi-Fi, Ethernet, USB 2.0 |

UltiMaker S6 is confidence in results. UltiMaker Cura software already contains profiles for hundreds of materials, saving you from lengthy setup. The flexible plate makes the final stage of the printing process as easy as its beginning. Any questions left? Call us: we have solutions for any tasks!