- Stock: In Stock

- Product code: GEN-74372153

- Shipping Weight: 12,360.00kg

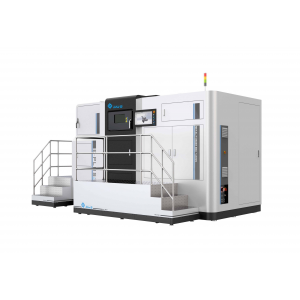

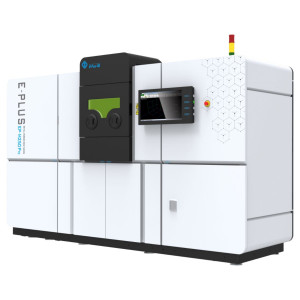

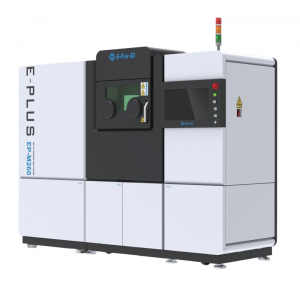

3D Metal Printer EP-M450 from E-PLUS 3D

The 3D metal printer EP-M450 is a professional dual-laser device with a build chamber size of 455 x 455 x 500 mm for the production of reliable and high-quality large-sized metal parts or serial production of small and medium-sized parts.

The EP-M450 is a highly efficient 3D printer for 3D printing from metal powder. A printer for large-scale production that offers bidirectional powder recoating and high printing speed of parts – up to 55 cm³/hour. The fully open E-PLUS 3D system makes the EP-M450 a very powerful tool for large manufacturers as they have complete freedom to choose the printing strategy using various metal powders such as stainless steel, titanium, aluminum, nickel alloys, etc., which helps control production costs.

Thanks to high efficiency, quality production and reliability, as well as ease of operation and integration of additive manufacturing into the overall production ecosystem, the EP-M450 metal 3D printer ensures that its owners stay one step ahead in their field of activity.

High Quality

- The density of printed parts reaches 99.9%, and the deviation of the mechanical properties of the parts is less than 5%.

- Optimized gas flow design ensures efficient removal of smoke and splashes, as well as achieving uniform and stable full-size printing.

- Dynamic software with the ability to divide the model into different parts (top and bottom surfaces, main areas, and small areas, etc.). Different process parameters can be individually applied to these parts to ensure high print quality.

- Repeatable positioning accuracy along the Z-axis in the build direction **<= ± 5 μm**.

- Overlap deviation in dual laser printing $\le \pm 0.1 \text{ mm}$. The overall mechanical properties of the printed part remain the same compared to the results of printing on a single laser machine.

High Efficiency

- The large build chamber size (chamber volume over 100 liters) allows for the printing of large-sized products or multi-series production.

- Time-saving printing technologies: selection of increased layer thickness, optimal scanning strategies – increase production capacity.

- Dual laser system with 500W fiber lasers each and a bidirectional powder recoating method increases printing efficiency by 70%.

- Layering speed up to 55 cm³/hour.

Reliability

- Sealed printing chamber with oxygen concentration support $<100 \text{ ppm}$ and stable pressure during printing.

- Control of raw material availability in the feeder with the ability to load it directly during printing.

- Double door protection of the chamber is achieved through double gas vent holes at the top of the printing chamber.

Economical and Easy Operation

- Perfect dual filtration system with reverse blowing extends filter life over 1000 hours.

- User-friendly interface along with one-click printing technology makes the preparation and printing process very simple.

- Ability to use different types of blades for applying metal powder, such as ceramic, polyurethane, alloy steel, etc.

- Gas consumption rate for printing less than 6 l/min reduces operating costs.

- Real-time printing process control using a sensor system and traceable printing records after each print.

Open System

- Flexible software with a user-friendly interface allows you to choose laser power, scanning speed and direction, layer thickness, model orientation; model division into parts with individual printing parameters, etc.

- In addition, there is the possibility to work with different types of raw materials on the market and from different manufacturers.

- Possibility of integration with Siemens NX software.

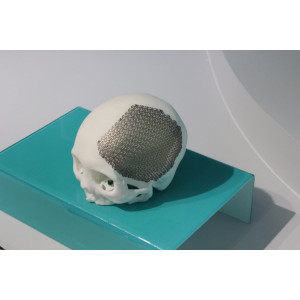

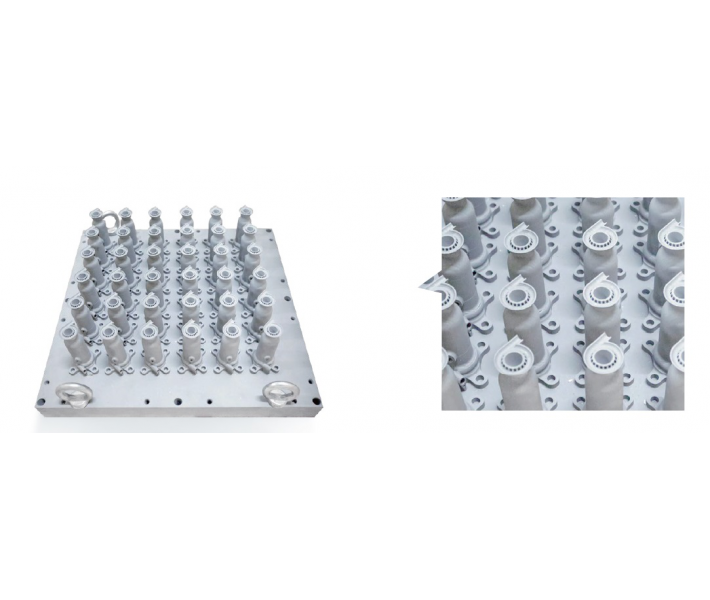

Examples of parts printed on the EP-M450 metal 3D printer:

3D Metal Printer EP-M450. Technical Specifications

| Build Chamber Size | 455 x 455 x 500 mm |

| Laser | Fiber laser. Single: 500 W or Dual: 2 x 500 W (Optional). |

| Laser Spot Size | 80-120 μm |

| Scanning System | High precision galvanometer |

| Maximum Scanning Speed | 8 m/s |

| Layer Thickness | 20 – 100 μm |

| Build Speed | Single laser: 15 – 35 cm³/hour; Dual laser: 25 – 55 cm³/hour |

| Material | Titanium alloy, aluminum alloy, nickel alloy, maraging steel, stainless steel, cobalt-chrome alloy, copper alloy, etc. |

| Power Supply | 380 V, 45 A, 50/60 Hz, 17 kW |

| Gas Supply | Ar/N₂ |

| Oxygen Content in Chamber | <= 100 ppm |

| Dimensions (W x D x H) | 5500 x 3300 x 3100 mm |

| Machine Weight | 10300 kg |

| Control Software | EPHatch, EPlus 3D |

| Input Data Format | STL or other convertible |

| Country of Manufacture | China |