- Stock: In Stock

- Product code: GEN-95919415

- Shipping Weight: 2,040.00kg

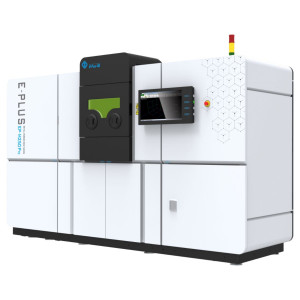

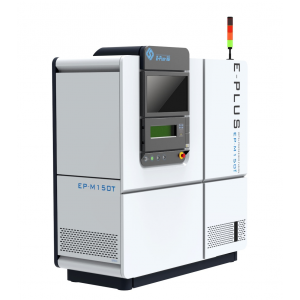

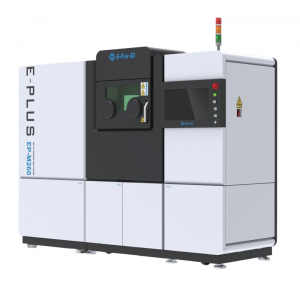

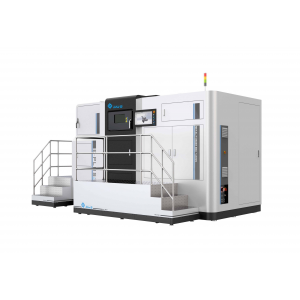

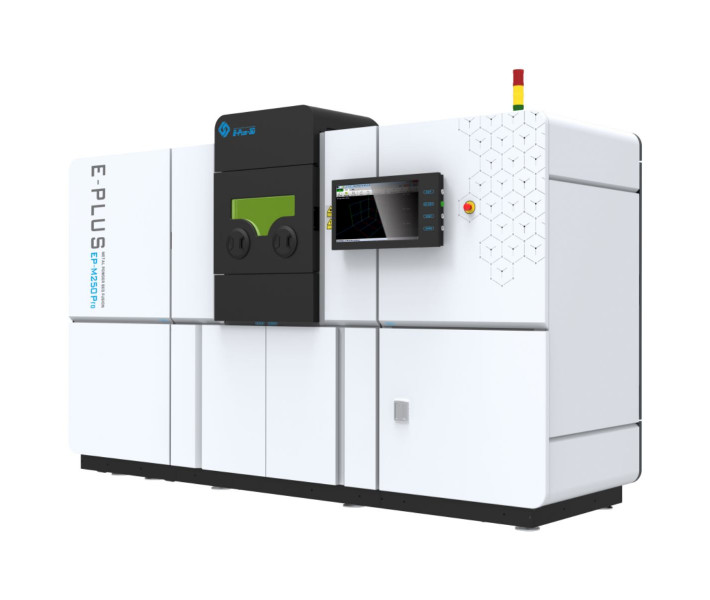

3D Printer EP-M250 Pro with SLM Technology from E-PLUS 3D

The SLM EP-M250 Pro 3D printer is a professional machine with a large build area and two lasers. It has the capability of maintenance without stopping the print. Excellent print quality from various metal alloys for medical, automotive, aviation, and other industrial applications.

The metal 3D printer EP-M250 Pro operates using the metal powder bed fusion (MPBF) technology from E-PLUS 3D. It can reliably and continuously operate without interruptions even during filter replacement, making it an excellent choice for large-scale production of medium-sized metal parts. It has an optimized metal powder supply system. Thus, printing takes a minimal amount of time, efficiently using raw materials. Additionally, it has low inert gas consumption during purging and printer operation. This maintains a protective environment inside the working chamber for product fusion.

High-Performance and Continuous 3D Printer EP-M250 Pro

- Dual-Laser system with a working volume of 262 x 262 x 350 мм.

- Continuous operation during filter replacement.

- Optimized overlap strategy reduces the time for applying a new powder layer.

- Precise laser beam quality control.

Economical

- The portioned powder supply and application system reduces raw material losses, thus using it economically.

- Enhanced filtration system significantly increases filter lifespan.

- Low inert gas consumption during purging and operation.

Reliability and Ease of Use

- Designed with a convenient powder recirculation system and equipped with access through a glove box for minimal contact with powder.

- Features intelligent software for minimal human involvement in the process.

- Real-time monitoring of the production environment and construction process.

Safe

- Innovative gas flow management system and optimized filtration system create conditions for clean air in the room.

- The sealed device enclosure minimizes oxygen content in the working chamber.

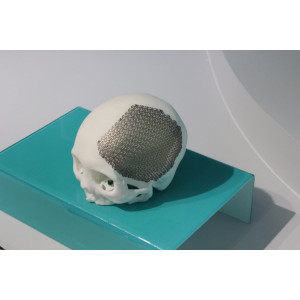

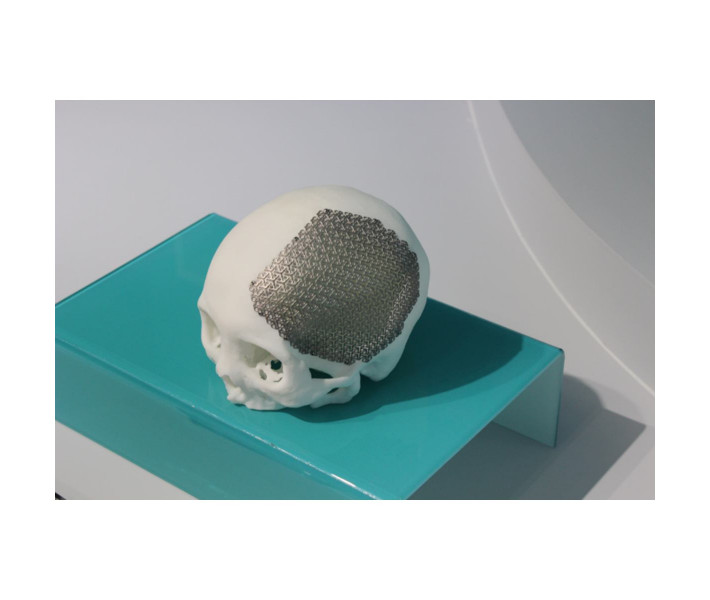

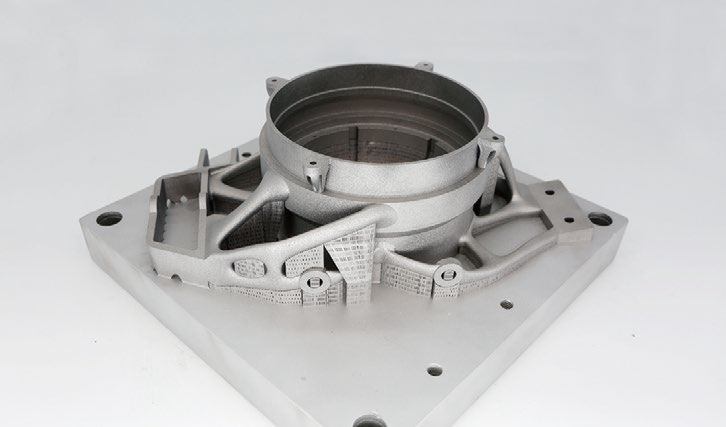

Examples of Parts Printed on the 3D Printer EP-M250 Pro:

Technical Specifications

| Build Volume (X * Y * Z) | 262 x 262 x 350 мм |

| Laser | Fiber laser, 500 Вт (one or two lasers optional) |

| Laser Spot Size | 70 мкм |

| Scanning System | High precision galvanometer |

| Maximum Scanning Speed | 8 м/с |

| Layer Thickness | 20 – 100 мкм |

| Build Speed | 5 – 20 см³/ч* |

| Material | Titanium alloy, aluminum alloy, nickel alloy, maraging steel, stainless steel, cobalt-chrome alloy, copper alloy, etc. |

| Power Supply | 380 В, 26 А, 50/60 Гц, 14 кВт |

| Gas Supply | Ar/N₂ |

| Oxygen Content in Chamber | ≤100 ppm |

| Dimensions (W * D * H) | 3500 x 1300 x 2300 мм |

| Machine Weight | 1700 кг |

| Control Software | EP Control, EP Hatch |

| Input Data Format | STL or other convertible |

| Platform Heating System | Available optionally, platform heated up to 200 °C |

| Country of Manufacture | China |

| Warranty | 1 year |