- Stock: In Stock

- Product code: GEN-89029443

- Shipping Weight: 1,800.00kg

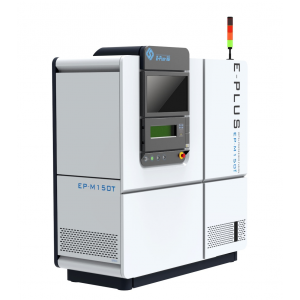

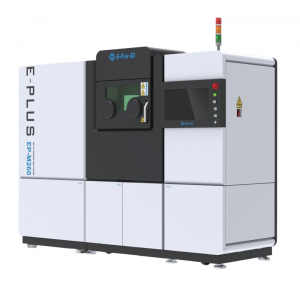

Purchase 3D Printer for Metal Printing SLM EP-M150 Pro

If you decide to purchase a 3D printer for metal printing for industrial production of parts in Ukraine, contact the specialists at the 3DDevice store.

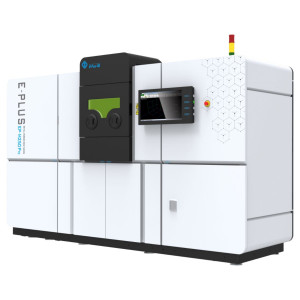

A distinctive feature of the EP-M150 Pro 3D printer is that it has the option to choose the printing mode with one or two high-power lasers simultaneously in an enlarged build chamber Ø 150 mm x 240 mm.

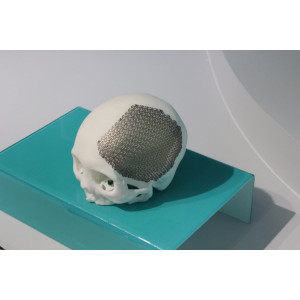

This printer operates using the Metal Powder Bed Fusion (MPBF™) technology. Layers of metal powder are sequentially sintered by one or simultaneously two lasers with a power of 200 and 500 W. Thus, the printer produces metal parts with high productivity and precision from powder materials such as: titanium alloy, aluminum alloy, nickel-based superalloy, maraging steel, stainless steel, cobalt, chromium alloy, etc. The fields of application for producing metal parts using MPBF™ technology are diverse and include: industrial production, medicine, education, dentistry, material development, instrumentation, automotive manufacturing, and more.

Advantages of EP-M150 Pro

- High Precision. The printer is equipped with lasers with high beam quality and a tiny laser spot. The lasers are well-coordinated with each other and have uniform beam quality from different locations in the build chamber.

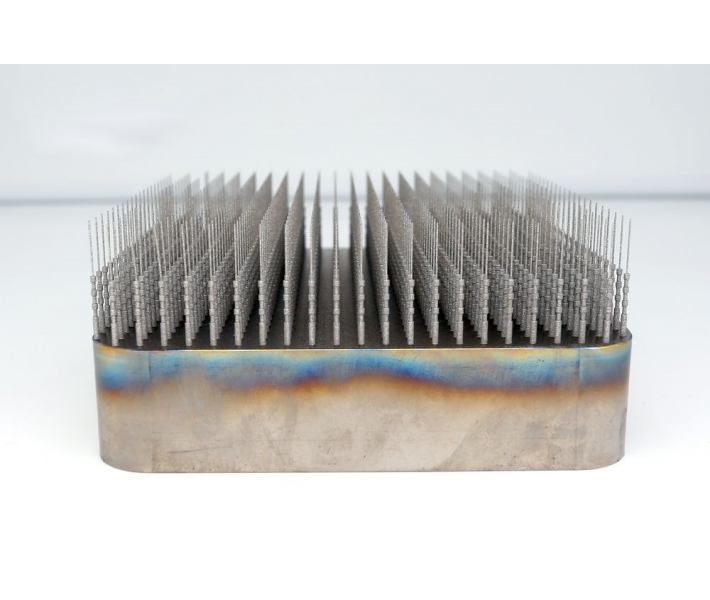

- High Productivity. A distinctive feature of additive technologies based on powder melting is their high productivity. This is achieved by the ability to densely pack parts in the build volume of the build chamber. The density of printed parts in the EP-M150 Pro can reach almost 100%.

- Volatility of Mechanical Properties <5%. In dual-laser printing mode, accuracy deviation in the alignment area is ≤ 0.15 mm.

- High Efficiency. The printer prints with a layer thickness of 50 -100 microns. Along with dual-laser printing mode, printing with a high layer thickness increases productivity by 2.3 – 2.7 times.

- Openness. The EP-M150 Pro 3D printer for metal printing is compatible with several materials. The same machine can print on several materials without adjusting the optical path. Several machines can simultaneously and consistently use the same set of process parameters.

- Convenient Operating System. Ergonomic interface, one-click printing. Easy replacement of working elements: replacing the filter element, residual material tank liner, and recoating device can be completed within 2 minutes.

- Economical Resource Consumption. The printer accurately doses and consumes powder. The printing process organization ensures a high material utilization rate. Air consumption during processing <3 l/min (0.3 MPa). Free material parameter packages.

- Safety. The printer is designed to ensure maximum safe operation. It has protection against electric shock and fire. It monitors the working environment and gas source in real-time, providing protection against waste and contamination.

Technical Specifications of 3D Printer for Metal Printing

| Optical System | Fiber Laser 200 W / 500 W (Single or Dual Laser Mode Optional) |

| Printing Technology | SLM |

| Build Chamber Size | Ø 150 mm x 240 mm (height adjustable) |

| Laser Spot Size | 60 microns |

| Layer Thickness | Laser 200 W: 20 microns – 50 microns Laser 500 W: 20 microns – 100 microns |

| Printing Speed | Parameter varies depending on equipment configuration and process parameters, as well as the number of lasers: One laser: 5 cm³ – 7.5 cm³ Two lasers: 8.5 cm³ – 12.75 cm³ |

| Gas Supply | Ar / N₂ |

| Oxygen Content | ≤ 100 ppm |

| Materials | Titanium alloy, aluminum alloy, nickel alloy, maraging steel, stainless steel, cobalt-chromium alloy, copper alloy, etc. |

| Power Supply | 220 V, 16 A, 50 ~ 60 Hz, 3 kW |

| Maximum Scanning Speed | 8 m/s |

| Input Data | STL or other converted file |

| Software | EP-Hatch; E-Plus 3D |

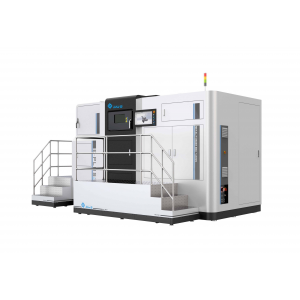

| Dimensions (W * D * H) | 2120 x 800 x 2000 mm |

| Machine Weight | 1500 kg |

| Country of Manufacture | China |

| Warranty | 1 year |