- Stock: Price on request

- Product code: 00-00011630

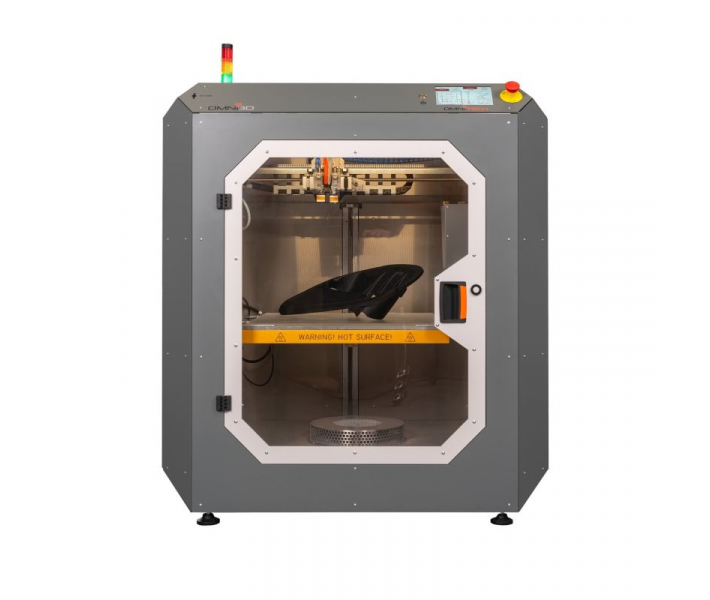

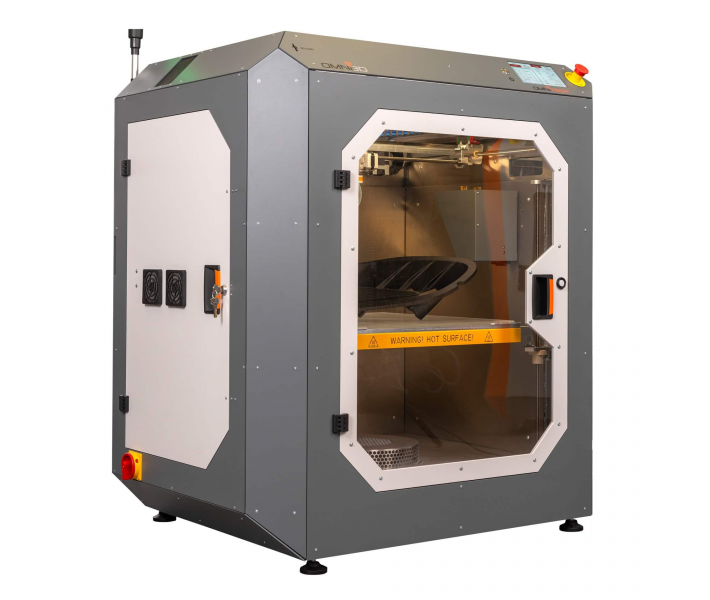

Omni TECH 3D Plastic Printer

The Omni TECH 3D plastic printer is reliable and has a large print area. It uses extrusion 3D printing technology.

Industrial Omni printers are known for their high accuracy of part size transfer. The Omni TECH 3D plastic printer has the following features:

- Patented water cooling technology for extruders.

- Heating with controlled air flow.

- Universal hardened steel nozzles compatible with all types of filaments.

- Wide connectivity options.

USB printing – full integration of USB and SD ports for improved functionality and ease of use of the device.

Omni TECH Auto Calibration

The printer is equipped with a fully automatic calibration system that simplifies the setup process and allows you to quickly start working. This is one of the key features that ensures high efficiency and speed of creating 3D printed objects.

No need to worry: just send the file to print, and then take the finished model. The device will do everything itself.

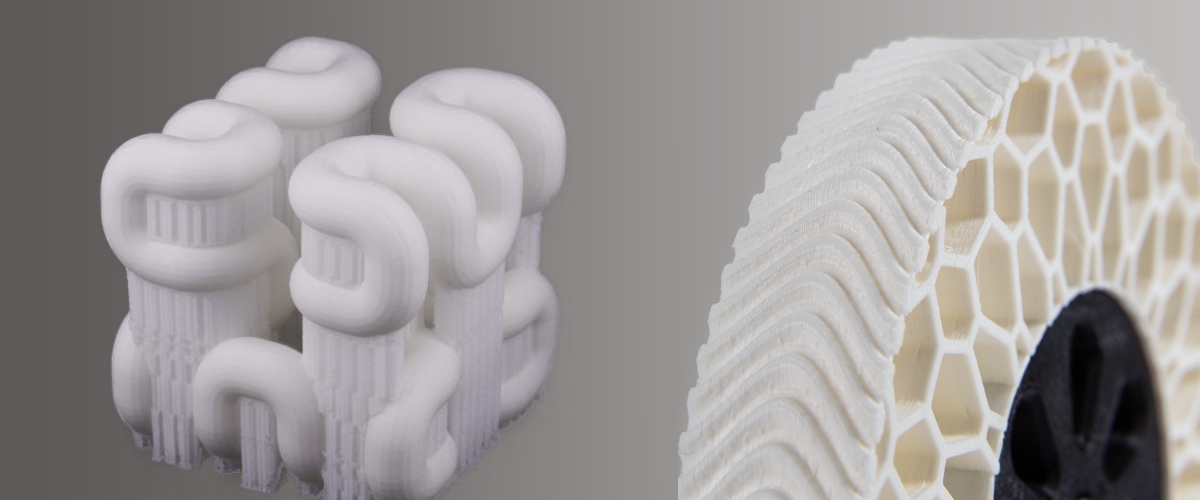

Two extruders – advanced 3D printing capabilities

The printer is equipped with a system for lifting the inactive print head, which improves print quality. Additionally, a high-temperature head is available, capable of operating at temperatures up to 500 ° C.

Closed heated work chamber

The heated chamber in the Omni TECH plastic 3D printer allows printing large parts from industrial materials, such as ABS. Temperature and air flow control ensure stable printing. In addition, the chamber is used to dry the filament. The chamber can also perform thermal expansion after the work is completed.

Large building volume

A large print area makes it possible to print large items or several small objects at the same time. This increases productivity.

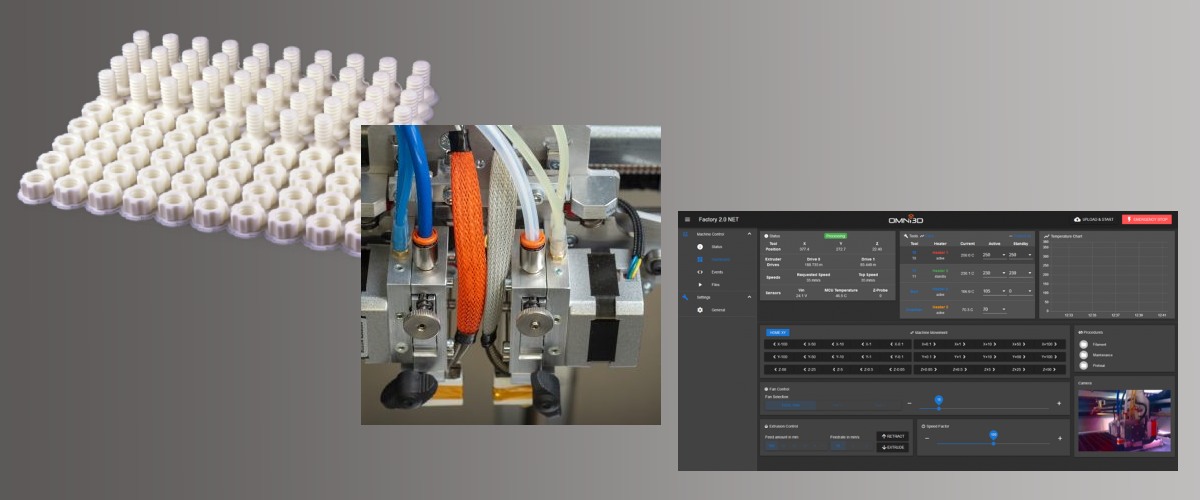

Water cooling system in the Omni TECH industrial 3D printer

The system reduces the temperature in the extruder by 40°C and effectively cools the upper part of the nozzles. This prevents the filament from overheating, keeping it stable during printing.

Remote Monitoring

The built-in camera allows you to monitor the printing process via a dedicated web page.

Manage a group of printers

Connection to the Factory 2.0 NET system allows you to create and manage a network of 3D printers. Each printer can be configured and controlled via a web interface, which simplifies remote printing and monitoring.

Wide range of applications for Omni TECH plastic 3D printers

Omni3D 3D printers feature high accuracy, repeatability and large working volume, making them an ideal choice for various industries:

- Automotive

- Education

- Heavy industry

- Light industry

- Medicine

- Transport

- Industrial design

- Car services

- Car personalization

- Automotive component manufacturing

Omni TECH Specifications | |

| Printing Technology FFF | FFF |

| Minimum Layer Height (microns) | 50 – 400 |

| Build Field (mm) | 500*500*570 |

| Plastic Ø (mm) | 1,75 |

| Maximum Nozzle Temperature (°C) | 360°C (optional 420 °C) |

| Number of Extruders 2 | 2 |

| Working Chamber Type | Closed |

| Filament Chamber Type | Closed |

| Chamber Heating | Yes |

| Plastic Drying | No |

| Automatic Calibration | Yes |

| Feed Mechanism Type | Direct |

| Extruder Design | Type Double head, electronic lifting system |

| Nozzle Diameter (mm) | 0.4, (0.6, 0.8 optional) |

| Size Accuracy (mm) | +/- 0.12% (not less than +/- 0.12 mm) |

| Printing Speed | 86 cm³/h |

| Maximum Chamber Temperature (°C) | 70 (active heating) |

| Maximum Platform Temperature (°C) | 150 (optional 170) |

| Platform Material and Features | Reusable sandwich structure with uniform heating, automatic calibration, glass ceramic working surface |

| Supported Materials | ABS-42, ABS V0, ABS FC, ASA-39, PC-ABS-37, PET-G-32, PETG CARBON, PA-12, PA 6/66 HD, TPU-93A, HIPS-20, ODS-20, PVA-20, CF PA-12, PLA, GF30-PA6, ALFATEICO, PEKK-A, ABS, FUSION+ and others |

| Air Filter | Carbon + HEPA (optional) |

| Control | 7″ LCD touch screen |

| Video Camera | Yes |

| Features | Emergency shutdown, HEPA filter (optional), door sensor, end of thread sensor, power failure protection |

| Supported File Types | STL, OBJ, 3MF, GCODE, FACTORY |

| Software | Simplifi 3D |

| Connection | SD-карта, USB, Ethernet, WLAN |

| Power Requirements | Power supply: 230 V / 50 Hz (optional 110 V / 60 Hz), Max. power consumption 2.2 kW |

| Country of Origin | Poland |

| Warranty Period (months) | 12 (with the possibility of extension) |

| Certificates | CE |

| Net Weight (kg) | 190 |

| Net Dimensions (mm) | 1200*1070*770 |

| Dimensions and weight in packaging | no data |

| Range of Operating Environment Temperatures (°C) | 15 – 35 |

System requirements: The 3D printer works autonomously from an SD card. Simplify3D software is installed on a computer with Windows, Linux, MacOS, and at least 2GB of RAM. The computer must be connected to the Internet at the time of activation.