3D друк Bugatti Divo: 3D технології в суперкарах

Виробник розкішних автомобілів Bugatti представив Divo — останню машину у лінійці сучасних надзвичайних суперкарів. Вона має демонстраційну 3D-друковану задню решітку та стоп-сигнали. Bugatti представили суперкар на заході в Монтереї, штат Каліфорнія, минулої п’ятниці. Було продано обмежену серію у 40 автомобілів всього за кілька годин.

Розгін у Divo трохи нижчий, ніж у попередньої Chiron, проте вона має відмінну керованість завдяки значній економії ваги та збільшенню притискної сили. Виробник стверджує, що Divo — найповороткіший автомобіль.

Естетика автомобіля, звісно, повністю суб’єктивна. На нашу скромну думку, Divo виглядає приголомшливо з усіх боків.

3D друк Bugatti Divo

«Divo — ще один приклад нашої філософії дизайну. Інженери та дизайнери прагнули створити транспортний засіб, орієнтуючись на швидкість проходження поворотів та бокову динаміку», — пояснює Ахім Аншайдт, директор з дизайну Bugatti.

«Наша задача полягала в тому, щоб розробити автомобіль, який відрізнятиметься від Chiron, але все ж одразу впізнавався як Bugatti», — додає Аншайдт.

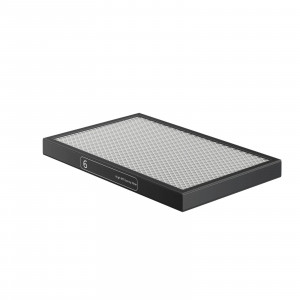

Складається з каскаду плавників, з яких 44 загоряються при включенні стоп-сигналів, цей масив тривимірних друкованих елементів є ще одним кроком на шляху широкого використання адитивного виробництва в автомобільній промисловості. Це не перше використання Bugatti 3D-друку при виробництві своїх автомобілів.

Для Bugatti, яка працює в лабораторії Volkswagen Group, це лише питання часу, коли адитивне виробництво охопить великі масштаби в автомобільній промисловості. Завдяки таким «піонерам» у цій сфері ми незабаром зможемо насолоджуватися 3D-друкованими деталями високої якості навіть у автомобілях, які бачимо щодня.

Залишити коментар