- Stock: In Stock

- Product code: 00-08800065

- Shipping Weight: 1.20kg

- SKU: RS-C2-FRGR-01

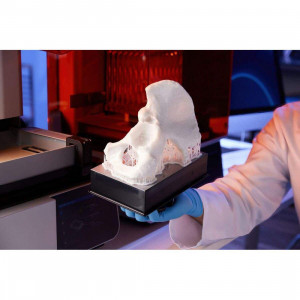

Flame Retardant Resin for Form 4

Flame Retardant Resin is a specialty material certified by UL 94 Blue Card to create self-extinguishing and halogen-free parts with favorable flammability, smoke, and toxicity (FST) characteristics. Use Flame Retardant resin to easily 3D print flame-retardant, heat-resistant, rigid, and creep-resistant parts that will perform well over time in environments and manufacturing facilities with high temperatures or ignition sources.

Tests and certifications include: UL 94 V-0 at 3 mm thickness for flammability; FAR 25.853 Appendix F, Part I for flammability; and ASTM E662 for FST. For full test results and certifications, please see the data sheet.

Why choose Flame Retardant Resin?

Accelerate time to market without the design constraints and upfront costs of traditional manufacturing with isotropic and highly detailed parts (XY resolution: 25 microns) with unlimited geometric freedom in any quantity (1 to 1000 parts) at any time.

- Certified flame retardant. Produce certified flame retardant, UL 94 V-0, and FAR 3D printed parts that meet the necessary certification requirements for persistent hazardous environments.

- Heat and creep resistance. The parts will perform well for a long time in closed and industrial environments with high temperatures or sources of ignition.

- Appearance of injection molded parts. Produce plastic parts with exceptional surface finishes that are far superior to other manufacturing methods such as FDM 3D printing.

- Stiff and functional. Produce rigid and functional parts with an elastic modulus of 2.9 GPa that can handle post-production operations such as threading, trimming, and drilling.

Application of Flame Retardant Resin

Flame Retardant Resin is a cost-effective solution for manufacturing self-extinguishing parts.

- Aircraft, automotive and railroad interior parts with excellent surface finish.

- Components of protective and internal consumer or medical electronics.

- Special fixtures, jigs and spare parts for industrial environments with high temperatures or ignition sources.

Specifications

| Printing technology | SLA | |

| Polymerization | Needed | |

| Layer height (microns) | Form 4/4B – 50, 100 | |

| Printer Compatibility | Form 4/4B | |

| Resin Tank Compatibility | Form 4 Resin Tank | |

| Build Platform Compatibility | Form 4 Build Platform, Form 4 Build Platform Flex | |

| Volume (L) | 0,84 | |

| Manufacturer Country | USA | |

| Post-cured at 70 ºC for 60 minutes | Post-cured at 80 ºC for 120 minutes | |

| Heat Deflection Temperature 0.45 Mpa | 94 ºC | 111 ºC |

| Heat Deflection Temperature 1.8 MPa | 71 ºC | 83 ºC |

| Tensile Modulus | 2,9 GPa | 3,1 Gpa |

| Ultimate Tensile Strength | 38,5 Mpa | 41,2 MPa |

| Elongation at Break | 9,4% | 7,1% |

| Notched Izod | 22,1 J/m | 22,4 J/m |

If you have any questions, please contact us.

Downloads

Technical Data Sheet, PDF (EN)