Ремонт виробів із пластику на 3D-принтері

3D-друк дуже зручний і вигідний для ремонту та відновлення найрізноманітніших виробів, тому його часто застосовують як у побуті, так і в різних ремонтних майстернях. Ремонт виробів із пластику на 3D-принтері – це простий та зручний процес, який не потребує значних витрат часу чи фінансів. Для відновлення пластикових деталей вам знадобиться лише їх 3D-модель, яку можна легко створити самостійно.

Якщо щодо рентабельності побутового ремонту за допомогою 3D-друку ще можна сперечатися, то користь 3D-принтерів для сервісних центрів складно переоцінити. У ремонтних майстернях, де кількість замовлень на відновлення пошкоджених виробів дуже велика, застосування тривимірного друку цілком виправдане. Особливо затребуваний ремонт пластикових виробів, які складно знайти у вільному продажу.

3D-друк у сервісних центрах

Останнім часом все більше ремонтних майстерень переходять на використання 3D-друку, і цьому є кілька вагомих причин:

- По-перше, 3D-друк – це швидко. Відтворення одного виробу методом тривимірного друку займає від кількох годин до кількох днів (залежно від складності та розмірів моделі). Для відновлення ексклюзивних деталей або при обмежених термінах це особливо важливо;

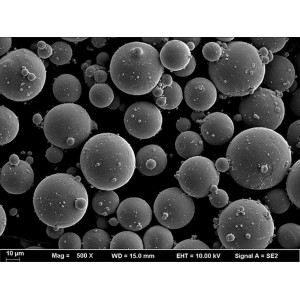

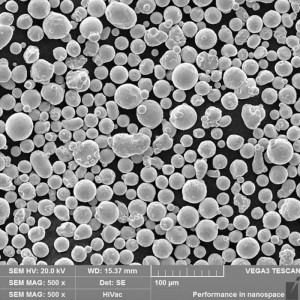

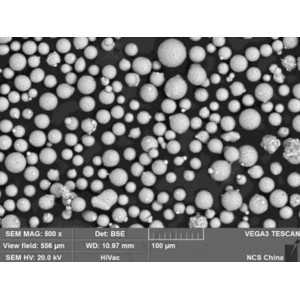

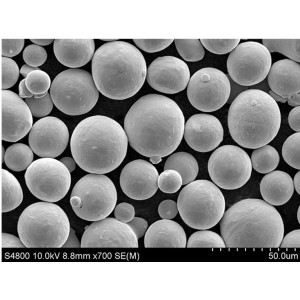

- По-друге, існує величезна кількість різноманітного пластику для 3D-принтерів. Пошкодженню та зносу підлягають будь-які деталі, і ключовим фактором є властивості 3D-пластику, з якого потрібно відтворити ідентичну деталь. З 3D-друком ремонт гнучких, міцних або стійких до хімічного впливу деталей не буде проблемою;

- По-третє, надрукувати можна все, що завгодно. Сучасні методики 3D-друку дозволяють виготовляти компоненти надзвичайно складної структури. А завдяки різноманітності пластику потреби будь-якого сервісного центру будуть задоволені;

- По-четверте, ремонт виробів із пластику таким методом вигідний фінансово. Особливо це стосується рідкісних та ексклюзивних компонентів, які важко знайти в продажу, а також оригінальних деталей від виробника, що коштують значні гроші. З 3D-принтером і базовими навичками 3D-моделювання ви самі можете стати виробником унікальних компонентів.

3D-принтери для ремонту

Переваги 3D-друку зрозумілі, але які саме вироби можна ремонтувати за допомогою 3D-принтера? Відповідь проста – абсолютно будь-які! Все, що виготовлено з пластику, можна відтворити методом тривимірного друку без особливих зусиль. Ось кілька прикладів застосування ремонту виробів із пластику за допомогою 3D-принтера:

- Відновлення шестерень різної конструкції;

- Виготовлення пластикових компонентів будь-яких механізмів;

- 3D-друк кріплень (для фото/відеотехніки, автомобілів, кабелів тощо);

- Відновлення корпусів різного розміру;

- Виготовлення заглушок, важелів та іншого.

Це лише мала частина того, де може знадобитися ремонт виробів із пластику. Насправді список можна розширювати нескінченно, адже з розвитком 3D-технологій зростає й сфера їх застосування.

Кожному, кого зацікавила 3D-друк у сервісних центрах та ремонт виробів із пластику за допомогою власного 3D-принтера, ми рекомендуємо завітати до нашого інтернет-магазину, де представлені різні моделі обладнання для 3D-друку. Тут ви знайдете настільні, професійні, SLA 3D-принтери та принтери по металу. Усі можливості 3D-друку для вашої роботи! Крім продажу обладнання, наша компанія надає послуги 3D-моделювання та 3D-друку. Замовлення можна зробити за телефоном або електронною поштою, вказаними у розділі «Наші контакти».

Залишити коментар