Відновлення пластикових виробів за зразком

На жаль, досконалих матеріалів не існує, і всі вони в тій чи іншій мірі піддаються впливу зовнішніх факторів, що може призвести до поломки або пошкодження виробу. Особливо це стосується практично всіх видів пластику, що використовуються в промисловості. Тому поломка, наприклад, бункера кавомолки може не бути великою несподіванкою, але точно створить незручності власнику. І тоді доведеться вирішувати: замінити пошкоджений об’єкт або замовити відновлення пластикових виробів.

У деяких випадках заміна пошкодженої деталі не викличе проблем. Проте якщо зламана унікальна, рідкісна або стара деталь, її заміна може бути складною. Першою проблемою може стати неможливість знайти потрібний компонент у продажу. Другою – занадто висока ціна необхідної деталі. І що робити, якщо її вартість практично дорівнює вартості всього пристрою? Вихід один – відновлення пластикових виробів. Деякі компанії займаються ремонтом пластику, але ми розглянемо відновлення виробів за пошкодженим зразком.

3D-друк для відновлення пластикових об’єктів

Для цієї мети відмінно підходить технологія 3D-друку, яка поступово набирає популярність у нашій країні. У чому суть підходу? Відновлення пластикових виробів відбувається на основі пошкодженого зразка. У результаті ви отримуєте ідентичний оригіналу виріб, готовий до виконання поставлених завдань. Початковий об’єкт при цьому залишається у вас. По суті, після 3D-друку у вас на руках залишаються два вироби – пошкоджений оригінал і нова 3D-друкована деталь. Процес створення виглядає так:

- Створення 3D-моделі на основі оригінального пошкодженого виробу. Можна використовувати технологію 3D-сканування з подальшою доопрацюванням даних у спеціальному ПЗ, або 3D-моделювання вручну за розмірами пошкодженого об’єкта;

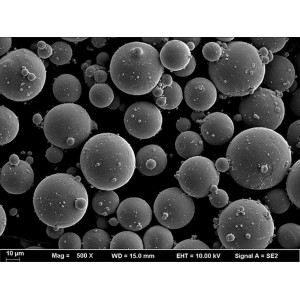

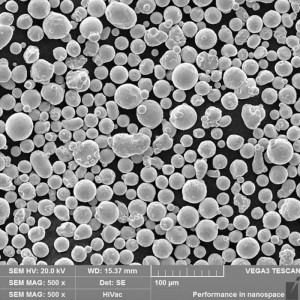

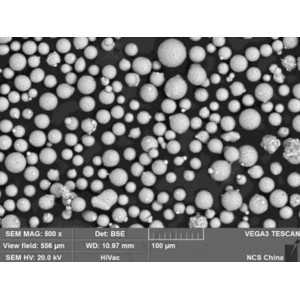

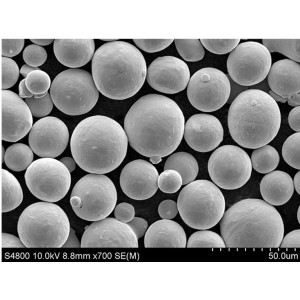

- Вибір оптимального матеріалу. Залежно від призначення деталі може знадобитися різний 3D-пластик. Сучасний ринок 3D-друку пропонує міцні, гнучкі, стійкі до хімічного впливу та інші матеріали;

- Створення управляючого коду для 3D-принтера. На цьому етапі програма-слайсер розраховує час друку та витрату пластику, а також встановлюються необхідні параметри друку;

- 3D-друк виробу. Розроблена 3D-модель відтворюється на 3D-принтері з обраного пластику. Готова деталь перевіряється на відповідність заданим розмірам. За потреби вносяться коригування в цифрову модель, і 3D-друк повторюється.

Замовити відновлення пластикових виробів

Відновлення пластикових виробів за допомогою 3D-принтера – простий та зручний спосіб отримати будь-яку деталь без зайвих витрат. Ви сплачуєте лише за витрату матеріалу, що часто значно менше, ніж ціна магазинної деталі. Такий підхід зручний як у домашніх умовах із власним настільним 3D-принтером, так і при замовленні 3D-друку у спеціалізованих сервісах.

Наша компанія виконує відновлення пластикових виробів за зразком від 150 грн (при наявності 3D-моделі). Ми обов’язково проводимо консультацію та разом з клієнтом підбираємо оптимальний матеріал для кожної деталі. Для замовлення пишіть нам на електронну пошту або телефонуйте за контактами з розділу «Наші контакти». Приклади наших робіт дивіться в розділі «Портфоліо».

Залишити коментар