Унікальна 3D шкіра

Технології 3D друку, і зокрема біопринтингу, активно розвиваються та дарують світу все нові неймовірні розробки, в реальність яких іноді важко повірити. Одним з останніх досягнень науковців стала унікальна 3D шкіра, створена для дуже цікавої мети. Її основне застосування — тестування косметичної продукції для азійського ринку.

Корені такого незвичайного винаходу лежать у надмірній орієнтації світової косметики на людей зі світлою шкірою. Це стосується не тільки тональних засобів, а й пудри, тіней та іншого. При цьому представники народів з іншим кольором шкіри стикаються з великими труднощами у виборі підходящої косметики. Насправді проблема глибша: різні типи шкіри відрізняються за рядом характеристик і по-різному реагують на засоби догляду. Тому, якщо цільовий ринок косметичної компанії орієнтований на один тип шкіри, для власників іншого типу її продукція може виявитися естетично чи біологічно непридатною. Китайська компанія Jala Group — місцевий виробник косметики — усвідомила цю проблему і розробила радикально новий спосіб оптимізації косметичних засобів безпосередньо для азійських споживачів.

3D шкіра для тестування косметики

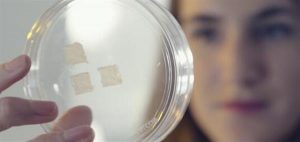

Спільно з французькою компанією LabSkin Creations організація взялася за проєкт п’ять років тому, а до кінця 2016 року вдосконалила власну методику біопринтингу настільки, що була готова представити новий сенсаційний продукт. Унікальна розробка дослідників — це 3D шкіра, яка отримала назву «Asian skin», що наочно відображає спрямованість проєкту. Участки такої шкіри виготовлені з людських стовбурових клітин на спеціальному 3D принтері і повністю імітують справжню живу тканину.

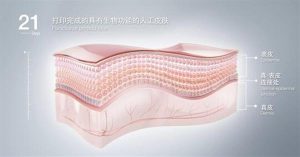

Для розробки власного процесу 3D- біодруку науковцям знадобилось 98 глибоких експериментів, але результат однозначно того вартий. 3D шкіра в пробірці функціонує абсолютно так само, як справжня шкіра представника азійських народів, і може застосовуватися для тестування косметики на безпеку та ефективність, а також для розробки нових косметичних продуктів. Ця дивовижна методика цікава не лише з точки зору кінцевої мети, а й як самостійний процес. Повідомляється, що на виготовлення функціонуючого елементу дерми, епідермісу та дермально-епідермального з’єднання потрібно всього три тижні. Однак такий результат — заслуга багатьох років наполегливої праці.

3D шкіра: методика створення

Для виготовлення одного невеликого шматочка штучної шкіри дослідникам спочатку довелося проаналізувати справжню людську шкіру. Після цього у цифровому середовищі була створена її 3D модель, яка потім переносилась за допомогою спеціального 3D принтера на структури, подібні до шкіри. В якості матеріалу використовувалися особливі біо-чорнила. В результаті отримувалися ділянки тканини, за зовнішнім виглядом та складом схожі на реальну шкіру. Отримана методика пізніше була запатентована компанією LabSkin Creations. Вона полягає у використанні різних елементів, включаючи стовбурові клітини людини, для швидкого виготовлення штучної шкіри. Нанесення біо-чорнил відбувається всього за 1 хвилину 56 секунд, подальший процес формування шкірних структур займає 21 день. За цей час 3D шкіра «дозріває», поки не набуде зовнішнього вигляду, складу та функцій справжньої шкіри.

Розробники впевнені, що 3D шкіра знайде широке застосування завдяки своїм перевагам:

- По-перше, тестування косметики буде точнішим, ніж аналогічні випробування на тваринах;

- По-друге, зміна «рецепту» біо-чорнил та маніпуляції зі стовбуровими клітинами можуть призвести до пошуку та розробки більш адаптованих, індивідуальних рішень для людей з різними типами шкіри.

Завдяки технології біопринтингу ми наближаємося до створення нового покоління натуральних продуктів з використанням інноваційних методик. А це допоможе виготовляти оптимальні товари для споживачів.

Залишити коментар