Шестерні на 3D-принтері

Звичайний FDM 3D-друк на настільних 3D-принтерах – найпростіший спосіб відтворення виробів, який підходить для широкого спектра завдань. Одне з таких завдань – виготовлення шестерень із пластику. 3D-принтери ідеально підходять для цього, забезпечуючи гнучкість налаштувань та високу продуктивність. На настільному пристрої для 3D-друку навіть можна організувати міні-станцію дрібносерійного виробництва пластикових шестерень.

Це лише одна з можливостей використання 3D-технологій, про яку детально розповідається в іншому розділі нашого сайту. Якщо розглядати виготовлення шестерень окремо, варто виділити кілька переваг, які надає користувачам 3D-друк. Одне з них – можливість виробництва ексклюзивних компонентів, недоступних у вільному продажі.

Переваги 3D-друку шестерень

Для виготовлення шестерень із пластику вигідно придбати 3D-принтер, якщо вам постійно доводиться самостійно виготовляти різні компоненти. У такому випадку виробництво шестерень повністю себе виправдає. Основні переваги 3D-друку:

- Повна свобода дій. Ви можете виготовляти шестерні будь-якого розміру, типу та конфігурації, достатньо мати відповідну 3D-модель. Жодних обмежень – будь-яка унікальна деталь може бути відтворена в об’ємі;

- Можливість поштучного та серійного виробництва. За допомогою власного 3D-принтера можна організувати дрібносерійне виробництво компонентів будь-якої складності, не кажучи вже про поштучне виготовлення шестерень;

- Різноманітність доступних матеріалів. Із великого вибору 3D-пластику легко обрати матеріал, який відповідає вашим потребам. Важлива міцність, гнучкість чи стійкість до масел – ринок 3D-матеріалів пропонує безліч варіантів;

- Доступна вартість. Особливо це помітно при виготовленні унікальних шестерень або серійних партій. У багатьох випадках 3D-друк обійдеться значно дешевше, ніж інші методи виготовлення або покупка готових деталей.

Виготовлення шестерень із пластику

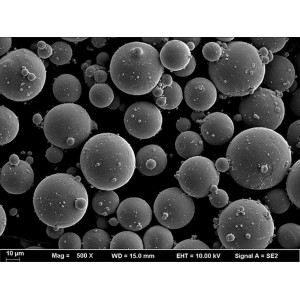

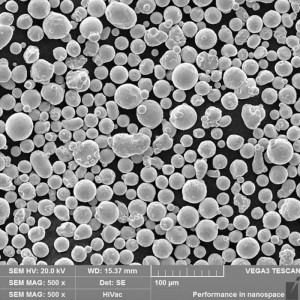

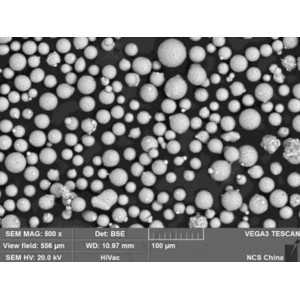

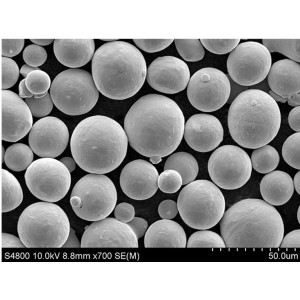

3D-друк шестерень відбувається у такій послідовності: спочатку створюється 3D-модель потрібної шестерні на основі оригіналу, креслень, ескізів або заданих параметрів. Далі обирається оптимальний 3D-пластик для кожної конкретної шестерні з урахуванням механічного навантаження та умов експлуатації. Після узгодження всіх параметрів файл 3D-моделі відправляється на друк.

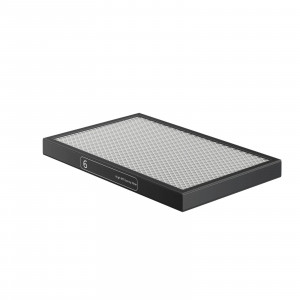

Також звертаємо вашу увагу на послуги нашої компанії: 3D-друк та 3D-моделювання будь-якої складності. Виготовлення шестерень – одне з наших основних напрямків. Приклади шестерень, з якими ми працювали:

- Циліндричні прямозубі;

- Циліндричні косозубі;

- Шевронні;

- Черв’ячні;

- Шестерні планетарної передачі;

- Конусні прямозубі;

- Вал-шестерні;

- Черв’ячні передачі.

Ми беремося за проекти будь-якої складності та готові допомогти реалізувати ваші ідеї. Приклади робіт нашої компанії дивіться в розділі «Портфоліо». Для замовлення телефонуйте або пишіть на електронну пошту, зазначені у розділі «Наші контакти».

Залишити коментар