- 1. Get a free Formlabs sample

- 2. Formlabs Clear Resin sample - liquid separator

- 3. Formlabs Grey Resin sample - rotating handle

- 4. Sample part made from Formlabs White Resin polymer - architectural model

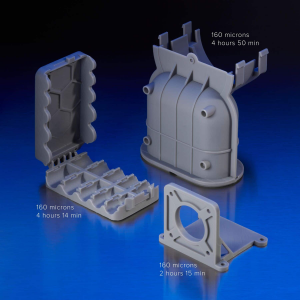

- 5. Detail made from Draft Resin - repeating brackets

- 6. Part made from Black Resin - pen

- 7. Sample part made from Grey Pro Resin - connector

- 8. Sample part made from Durable Resin - gear assembly

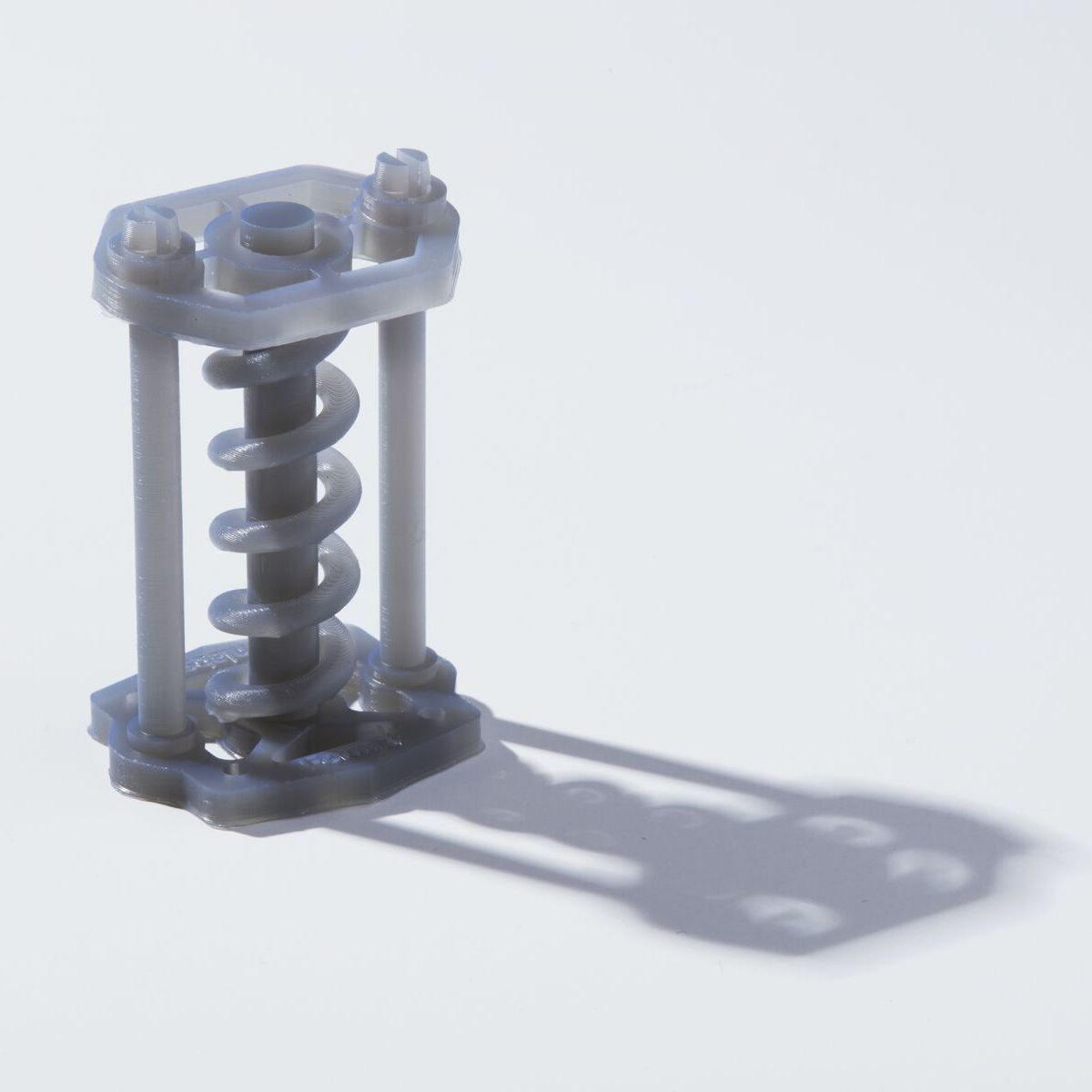

- 9. Sample part made from Tough 1500 Resin - spring

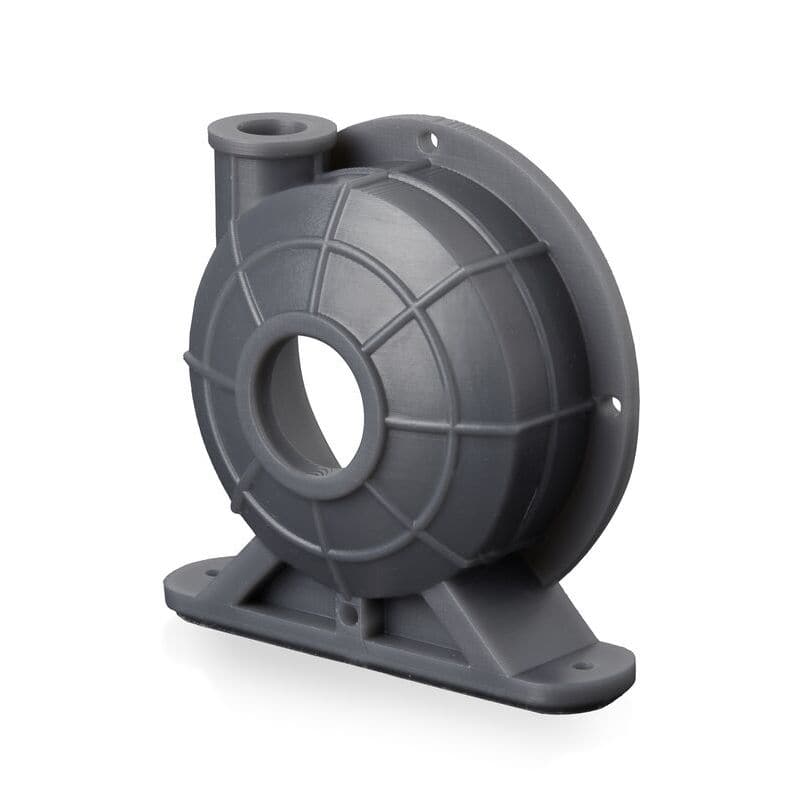

- 10. Sample part made from Tough 2000 Resin - pump housing

- 11. Sample of an engineering part made from High Temp Resin - hair dryer nozzle

- 12. Sample part made from Rigid 4000 Resin - impeller

- 13. Free Formlabs sample part made from Rigid 10K Resin - multitool

- 14. Sample made from soft, elastic Elastic 50A Resin - artery

- 15. Free Formlabs sample made from Flexible 80A Resin flexible polymer

- 16. Model made from Castable Wax Resin jewelry material - ring with three stones

- 17. Jewelry model made from Castable Wax 40 Resin - solid ring

- 18. Sample jewelry model made from High Temp Resin - pavé ring

- 19. Sample made from BioMed Clear Resin - BiPAP adapter to ventilator

- 20. Sample printed from Nylon 11 on a Formlabs Fuse 1+ 30W SLS 3D printer

- 21. Sample printed from Nylon 12 on a Formlabs Fuse 1+ 30W SLS 3D printer

Getting a free Formlabs sample to evaluate the quality of 3D printing is easy!

Contact our managers using the contact details provided on our website or fill out the form below. We will send you a free part made from the material of your choice. You can find a list of models below in this article.

Want to see for yourself the quality of the materials used for 3D printing on Formlabs Form 3, Form 4, or Formlabs Fuse powder-based 3D printers?

All you need is a sample printed from photopolymers developed and manufactured by Formlabs. We will send you a free sample part printed on a Form 3, Form 4, or Fuse 1+ 3D printer. With it, you can evaluate the quality of 3D printing and the functional features of the material.

Get a free Formlabs sample

To receive a free sample of Formlabs polymer, please complete the form:

Formlabs Clear Resin sample - liquid separator

A Clear Resin polymer part printed on a Form 3 3D printer. Models made from this material have a polished surface of stunning quality. In addition, such parts are virtually optically transparent. The polymer is ideal for working with light or demonstrating internal functions.

- High resolution

- Has a clear, optically transparent surface

- No additional polymerization required

Formlabs Grey Resin sample - rotating handle

Free Formlabs sample made from Grey Resin. The material is used for prototyping and general-purpose design, and is ideal for capturing fine details.

- High resolution

- Clean matte surface that perfectly conveys fine details

- No post-curing required

Sample part made from Formlabs White Resin polymer - architectural model

White Resin makes it easy to print smooth surfaces and details. It is ideal for finished presentations or as a base for painted prints.

- High resolution

- Surface cleanliness

- No post-curing required

Detail made from Draft Resin - repeating brackets

Free Formlabs sample made from Draft Resin photopolymer. This photopolymer prints parts 4 times faster than other standard resins. It is the ideal material for iterative prototyping. This sample part contains three brackets connected to a raft, allowing you to test the ease of removing the support. A single bracket can be printed in just 17 minutes using Draft Resin.

- Initial prototypes

- Fast iterations

- High throughput

Part made from Black Resin - pen

Black Resin is designed for 3D printing models with very thin elements and intricate details.

- High resolution

- Clean matte surface

- No post-curing required

Sample part made from Grey Pro Resin - connector

Grey Pro universal Resin is ideal for conceptual modeling and functional prototyping, especially for parts that will be processed multiple times.

Material properties:

- Tensile strength — 61.2 MPa

- Tensile modulus — 2.6 GPa

- Flexural modulus — 2.0 GPa

- Elongation at break — 13.0%

Sample part made from Durable Resin - gear assembly

Durable Resin is used to print parts with a smooth glossy surface and high resistance to deformation. This material has a low modulus of elasticity, high elongation, and high impact strength. Use this material for parts that require minimal friction.

Material properties:

- Tensile strength — 28 MPa

- Tensile modulus — 1.0 GPa

- Joule toughness — 114 J/m

- Heat distortion temperature — @ 0.45 MPa 41 °C

Sample part made from Tough 1500 Resin - spring

Tough 1500 Resin allows you to produce rigid and flexible parts that bend and compress quickly under cyclic loading. The combination of stiffness and elongation in this resin allows this spring to compress and return to its shape repeatedly. This sample is an assembly of three parts: a base, a spring mounted on supports, and an upper part that presses against the spring.

Material properties:

- Tensile strength — 33 MPa

- Tensile modulus — 1.5 GPa

- Joule toughness — 67 J/m

- Heat distortion temperature — @ 0.45 MPa 52 °C

Sample part made from Tough 2000 Resin - pump housing

This pump housing demonstrates the strength of Tough 2000 Resin.

Tough 2000 is the strongest and most rigid material in Formlabs' Tough and Durable Resin family. This makes it ideal for prototyping durable parts that should not bend easily.

Material properties:

- Tensile strength — 46 MPa

- Tensile modulus — 2.2 GPa

- Joule fracture energy — 40 J/m

- Heat deflection temperature — @ 0.45 MPa 63 °C

Sample of an engineering part made from High Temp Resin - hair dryer nozzle

High Temp Resin V2 can withstand thermal loads of up to 238 °C at 0.45 MPa. This makes it ideal for static applications that will be exposed to higher temperatures.

Material properties:

- Heat deflection temperature — @ 0.45 MPa 238 °C (for material version V2) and 289 °C (version V1)

Sample part made from Rigid 4000 Resin - impeller

Rigid 4000 Resin is reinforced with glass. This provides high rigidity and a polished surface. It is ideal for rigid and durable parts that can withstand minimal deflection. It is used to print parts with thin walls.

Material properties:

- Tensile strength - 75.2 MPa

- Tensile modulus - 4.1 GPa

- Bending modulus - 3.7 GPa

Free Formlabs sample part made from Rigid 10K Resin - multitool

Rigid 10K Resin is the stiffest material in the Formlabs engineering family. This glass-filled material mimics the strength of glass and fiber-reinforced thermoplastics. This multifunctional tool includes a slotted screwdriver, bottle opener, and three hex keys, demonstrating the material's resistance to deformation under various forces and torques.

Material properties:

- Tensile strength — 65 MPa

- Tensile modulus — 10 GPa

- Flexural modulus — 9 GPa

Sample made from soft, elastic Elastic 50A Resin - artery

Elastic 50A Resin is Formlabs' softest engineering resin. It is suitable for printing parts that will bend, stretch, compress, and withstand repeated cycles without breaking. This sample is a designer's interpretation of a pulmonary artery.

Material properties:

- Tensile strength — 3.32 MPa

- Relative elongation at break — 160%

- Tensile strength — 19.1 kN/m

- Compression set at 70C — 9%

- Shore hardness — 50A

Free Formlabs sample made from Flexible 80A Resin flexible polymer

Flexible 80A Resin is the stiffest of Formlabs' flexible and elastic resins, with a Shore hardness of 80A. It mimics the flexibility of rubber or TPU. Balancing softness and strength, Flexible 80A resin can withstand bending and compression even during repeated cycles. It is the choice for stiffer flexible parts that slowly return to their shape after deformation. Supports print resolutions of 100 and 50 microns. Post-curing is required.

Material properties:

- Tensile strength — 8.9 MPa

- Relative elongation at break — 120%

- Tensile strength — 24 kN/m

- Shore hardness — 80A

Model made from Castable Wax Resin jewelry material - ring with three stones

Castable Wax Resin jewelry polymer accurately prints the most complex jewelry details thanks to its high strength. This resin contains 20% wax for clean and reliable casting that replicates traditional casting technology. Formlabs recommends this material for fittings and direct casting of filigree and thin items with small details using lost wax models. For excellent repeatable results, simply follow the manufacturer's recommended burnout schedule.

Features:

- Lightweight intricate jewelry

- One material for prototyping and production

- No additional curing required

Jewelry model made from Castable Wax 40 Resin - solid ring

Castable Wax 40 Resin, a jewelry-grade wax-filled polymer, provides exceptional casting characteristics for the most complex projects. Castable Wax 40 contains a 40% blend of hard and soft waxes. With its low thermal expansion, it is the recommended material for direct casting in a wide range of styles, from heavy-duty rings and medallions to lightweight wedding jewelry.

Features:

- Cleanly cast stone settings, embossed text, and heavy items

- Use of plaster molding and standard burnout

- No additional curing required

Sample jewelry model made from High Temp Resin - pavé ring

Formlabs High Temp Resin is also recommended for use in room temperature vulcanization (RTV) and high-temperature natural rubber vulcanization processes. Vulcanization allows you to create a mold capable of producing multiple copies of wax models for a faster and easier wax burnout process.

Features:

- Heat deflection temperature — @ 0.45 MPa 238 °C

Sample made from BioMed Clear Resin - BiPAP adapter to ventilator

BioMed Clear Resin is a strong, durable material for biocompatible applications that require prolonged contact with skin or mucous membranes. This USP Class VI-certified material is suitable for applications that require wear resistance and low water absorption over time. Parts printed with BioMed Clear Resin are compatible with standard sterilization methods. BioMed Clear Resin is manufactured at Formlabs' ISO13485 facility and is supported by an FDA device master file.

Features:

- Medical equipment and device components

- Ventilator components and PPE

- Biotechnology equipment

- Drug delivery devices

- Research and development

Sample printed from Nylon 11 on a Formlabs Fuse 1+ 30W SLS 3D printer

Nylon 11 powder is a highly effective material for functional prototyping and small-batch production. It is designed for manufacturing highly flexible and durable parts. This sample demonstrates a durable case printed with Nylon 12 powder and an insert printed with Nylon 11 powder, featuring a locking clip that opens when a sturdy button is pressed.

- Case: Nylon 12 Powder

- Insert: Nylon 11 Powder

Features:

- Impact-resistant prototypes, fixtures, and jigs

- Thin-walled air ducts and enclosures

- Buttons, clips, and hinges

- Orthopedics and prosthetics*

*Material properties may vary depending on part design and manufacturing practices. The part manufacturer is responsible for verifying the suitability of printed parts for their intended use.

Sample printed from Nylon 12 on a Formlabs Fuse 1+ 30W SLS 3D printer

Nylon 12 powder combines strength and detail. It is a highly effective material for both functional prototyping and end-use applications of complex assemblies and durable parts with high environmental sustainability. Printed on the Fuse 1 without supports, this durable enclosure includes moving components printed together and an internal map demonstrating the printed features.

Features:

- High-performance prototyping

- Low-volume production

- Permanent fixtures and tools

- Biocompatible, sterilizable parts*

*Material properties may vary depending on part design and manufacturing practices. The part manufacturer is responsible for verifying the suitability of printed parts for their intended use.

Leave a Comment