3D друк Tesla!

Навряд чи буде перебільшенням назвати електромобіль справжнім досягненням людства, здатним кардинально змінити світ. У умовах стрімкого погіршення екологічної ситуації все більше людей обирають екологічно чистий транспорт. Компанія Tesla Motors лідирує у світовому виробництві автомобілів на електродвигунах і постійно вдосконалює технології виготовлення та управління своїми машинами.

3D друк Tesla

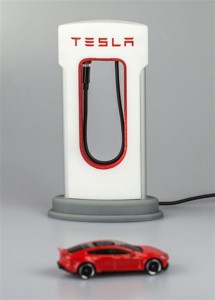

Наприклад, їхні оригінальні зарядні станції «Tesla Supercharger» вже широко поширені у світі, і їхня кількість постійно зростає, що дозволяє водіям електромобілів не обмежувати себе у подорожах. Такий підхід значно сприяє популяризації автомобілів Tesla.

3D друк Tesla

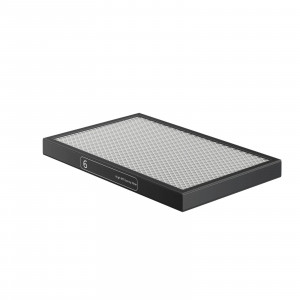

Успіх електромобілів надихає окремих людей на створення не таких глобальних, але дуже корисних винаходів. Так, Мартін Хансен, ентузіаст 3D друку та власник Tesla із Північної Німеччини, розробив повністю функціонуючу мініатюрну репліку зарядної станції Tesla Supercharger для зарядки мобільних телефонів.

3D друк Tesla

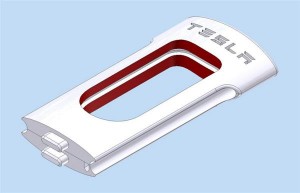

Ідея створення пристрою з’явилася у нього ще у 2014 році, і він довго працював над її реалізацією. Механізм, створений за допомогою 3D принтера, зовні нічим не відрізняється від оригіналу, повністю повторюючи дизайн. На жаль, на відміну від справжньої станції, швидкість зарядки буде звичайною. Модель складається з шести частин, які легко зібрати, і сумісна з будь-яким USB-кабелем.

3D друк Tesla

«Я провів майже весь вільний час, досліджуючи Tesla Motors та Model S», — розповідає Хансен. «Одного разу, відвідавши зарядну станцію, я зрозумів, що мережа станцій Supercharger є ключем до успіху Tesla, і кожен власник автомобіля хотів би мати власну станцію вдома».

3D друк Tesla

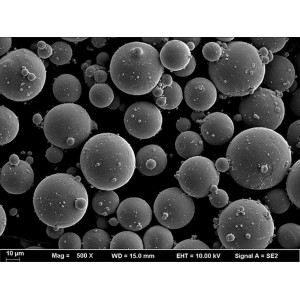

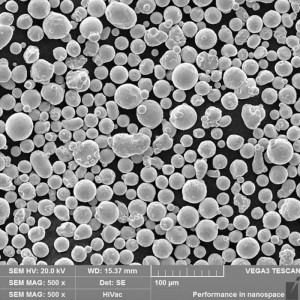

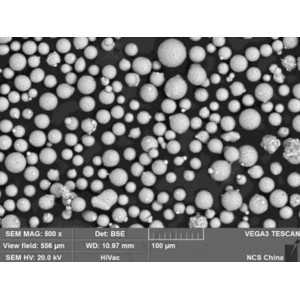

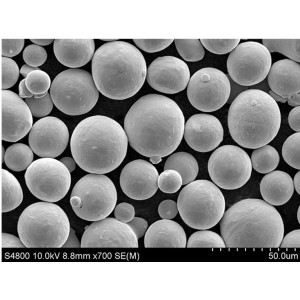

Мініатюрна станція Мартина дійсно заслуговує похвали, адже це його перший досвід роботи з 3D технологіями. Хансену знадобилися місяці, щоб освоїти 3D моделювання. Практично всі деталі були надруковані на 3D принтері Zortrax M200 з білого ABS-пластику, окрім кількох елементів, виготовлених за технологією SLS сторонніми виробниками. Бокові частини станції виконані з алюмінію.

3D друк Tesla

Бажаючи поділитися дизайном з шанувальниками Tesla, Хансен розмістив STL-файли мініатюрної станції Supercharger на своєму сайті, щоб кожен охочий міг отримати унікальний 3D-друкований пристрій та цікаво підкреслити свою індивідуальність.

Залишити коментар