Новини Formlabs

0

388

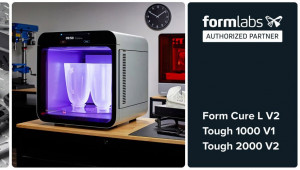

Зустрічайте нові продукти Formlabs цієї осені!

У четвер, 13 листопада 2025 року, Formlabs оголосила про реліз трьох ключових новинок, які посилюють

можливості

адитивного виробництва та допоможуть бізнесам перейти від прототипування до стабільного серійного

випуску.

Ці продукти вже доступні для замовлення в Україні через 3DDevice.

Нові міцні To..

0

1503

Просунуті методи постобробки в 3D-друці

Компанія 3DDevice запрошує інженерів, дизайнерів і всіх, хто працює з адитивними технологіями, на безкоштовний

вебінар, присвячений сучасним методам обробки 3D-друкованих деталей.

Дата проведення: 30.07.2025

Час: 11:00

Формат: Zoom

Програма вебінару

Під час вебінару ми розглянемо, як правильн..

0

1275

Презентація 3D-принтера Formlabs Form 4L

15 жовтня компанія Formlabs презентувала свій новий фотополімерний MSLA 3D принтер Form 4L –

широкоформатний і блискавично-швидкий.

3DDevice запрошує всіх бажаючих на презентацію Form 4L:

Дата: 30.10.2024 о 11:00 за Києвом

Спікер: Юртаєв Арсеній

..

0

1426

Полірувальна машина Formlabs Fuse Blast вже в Україні!

Автоматизована піскоструминна камера Formlabs Fuse Blast, розроблена для системи SLS 3D-друку Formlabs Fuse – вже

доступна в Україні.

Компанія 3DDevice, як авторизований партнер Formlabs в Україні та Молдові, отримала першу партію цих полірувальних

машин.

Fuse Blast – це автоматизована

сист..

0

1716

Новий Formlabs Form 4: до 4 разів швидший SLA друк

17 квітня 2024 року Formlabs представили свій новий 3Д-принтер Form 4 - нове покоління фотополімерних

3Д-принтерів цієї відомої американської компанії.

Серія Form 4 отримала ряд технологічних оновлень, які стають істотними перевагами, щоб задуматися про покупку

фотополімерного 3Д-принтера:

Но..

0

1646

Як отримати знижку 16000 грн за рекомендацію Formlabs?

Нова Реферальна програма Formlabs – це вигідна можливість отримати знижку на продукти Formlabs!

Порекомендуйте 3Д-принтери Formlabs своїм друзям та знайомим, які ще не мають принтерів Formlabs, і кожний із вас

отримає по 16 тис. грн знижки:

Поточні власники 3Д-принтерів Formlabs отримають знижку ..

0

1301

Оновлення PreForm 3.34.0 розширює можливості 3D-друку

Нова версія програмного забезпечення Formlabs PreForm 3.34.0 розкриває нові можливості для 3D-друку

як за технологією SLA, так і SLS.

Для Fuse 1+ 30W:

Швидкість друку на 25% вища, ніж у попередній версії програмного забезпечення,

і в три рази швидше, ніж у оригінального Fuse 1.

..

0

1143

Екосистема Автоматизації фотополімерного 3D друку Formlabs

Екосистема Автоматизації 3D друку Formlabs – серійний 3D друк у вас у майстерні.

4 січня Formlabs представили свою Automation Ecosystem – Екосистему Автоматизації фотополімерного 3D друку. Це

комплексне рішення, яке дозволяє перетворити ваш парк LFS 3D принтерів Formlabs Form 3, Form 3+, Form 3B або

..

0

1151

Нові БіоМед матеріали Formlabs

Сімейство фотополімерів для медичного 3D друку – поповнюється. 12 квітня Formlabs представили два нових фотополімери

для виробництва біосумісних, стерилізованих та жорстких деталей для кінцевого використання: BioMed Black

Resin та BioMed White

Resin.

Ці два непрозорі матеріали медичного призначення..

0

868

Нова антистатична смола Formlabs ESD Resin

4 січня компанія Formlabs представила свою

нову розробку: смолу Formlabs ESD Resin, яку вони позиціонують як міцний матеріал,

здатний розсіювати накопичення статичної електрики.

Завдяки своїм антистатичним властивостям та міцності, ESD Resin ідеально підходить для виготовлення:

Інструментів т..

0

872

Новий 3D принтер Formlabs Form 3+ та Form 3B+У вівторок, 4 січня 2022 року Formlabs оголосили про вихід свого нового обладнання: це універсальний 3D-принтер Form 3+ та біосумісний 3D-принтер Form 3B+, які сприятимуть розвитку промислового 3D-друку та допоможуть втілити ідеї в життя швидше, ніж будь-коли.Що нового в Form 3+ і Form 3B+?Удосконалення програмного забезпеч..

0

1171

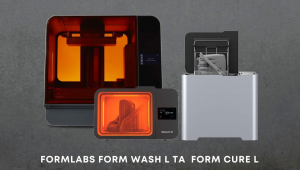

Мийка та сушарка для 3D принтера Formlabs Form 3L та Form 3BL

Мийка та сушарка для Form

3L – необхідні елементи, які завершують досконалий 3Д друк на цьому 3Д принтері.

Чудова новина, на яку всі так чекали!

26 жовтня 2021 року компанія Formlabs анонсувала вихід на ринок цих широкоформатних машин для подальшої обробки, Form Wash L та Form Cure L.

Вони д..